An automatic weighing and weight sharing system suitable for steel pipe plants

An automatic weighing and steel pipe factory technology, applied in weighing, special scales, measuring devices, etc., can solve the problems of automatic weighing and weight sharing of steel pipes, the deviation between actual weight and theoretical weight, and low accuracy, etc., to achieve Improve sales management efficiency, reduce manpower and material resources, and achieve efficient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

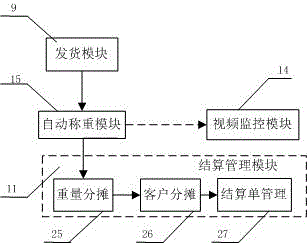

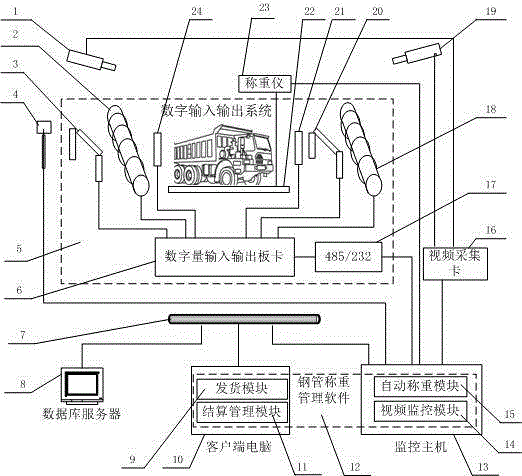

[0031] 1) Delivery: The operator enters the delivery order management interface in the delivery module 9 of the client computer 10, and inputs the following information: purchase unit, card number, vehicle number, product name, specification, number of pieces, loose branch (not enough Scattered number of pieces for a whole piece) unit price per ton and unit price of branch (note: only one unit price per ton or unit price of branch should be filled in). Multiple records can be filled in one order. If you make a mistake, you can modify or delete it and fill it out again. Enter the settlement document management interface and enter the following information: settlement unit, settlement amount, settlement by ton / payment, arrears, acceptance, rebate, discount, addition, settlement method, sales order category and remarks. Multiple settlement customers can be filled in. After the information input is completed, the operator sends the registered radio frequency card to the truck dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com