Spacecraft real object tracking system and method based on RFID

A tracking system and spacecraft technology, applied in the field of spacecraft physical tracking system, can solve the problems of untimely physical tracking and inaccurate positioning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

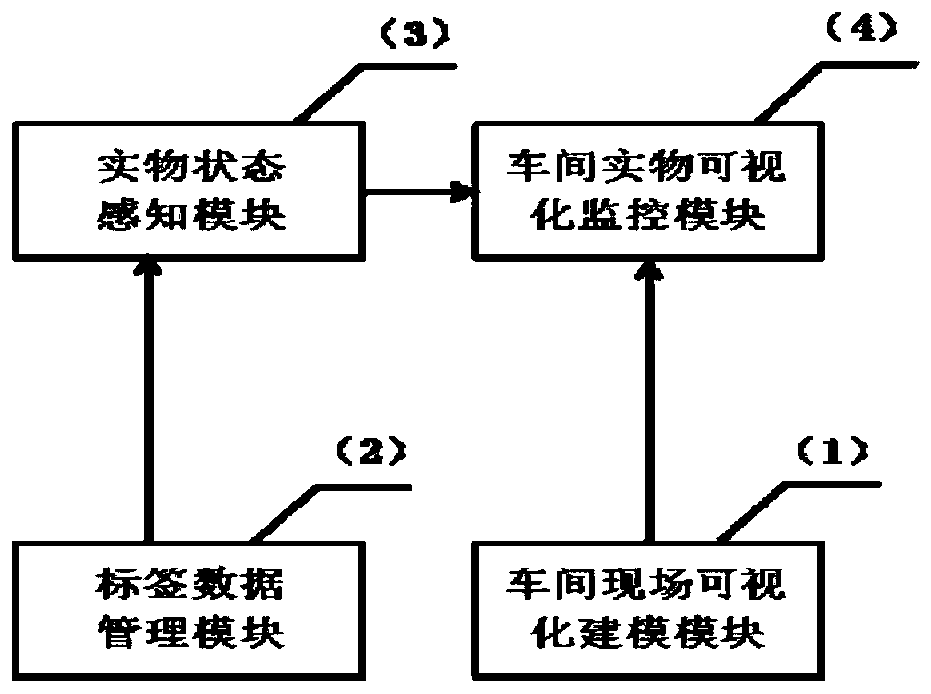

[0027] RFID-based tracking and management system for spacecraft physical objects, including: workshop site visual modeling module (1), tag data management module (2), physical object status perception module (3), workshop physical object visual monitoring module (4), such as figure 1 shown.

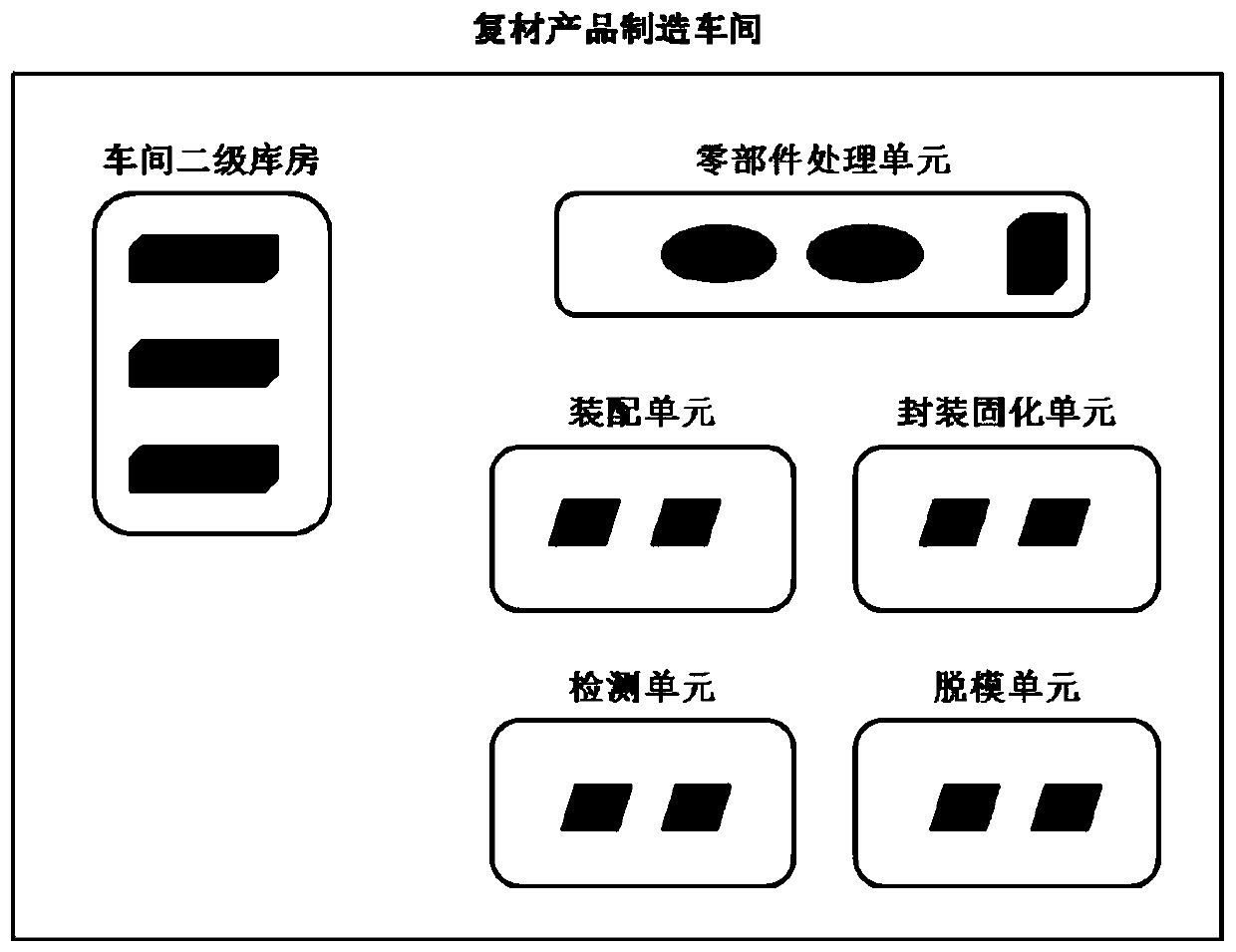

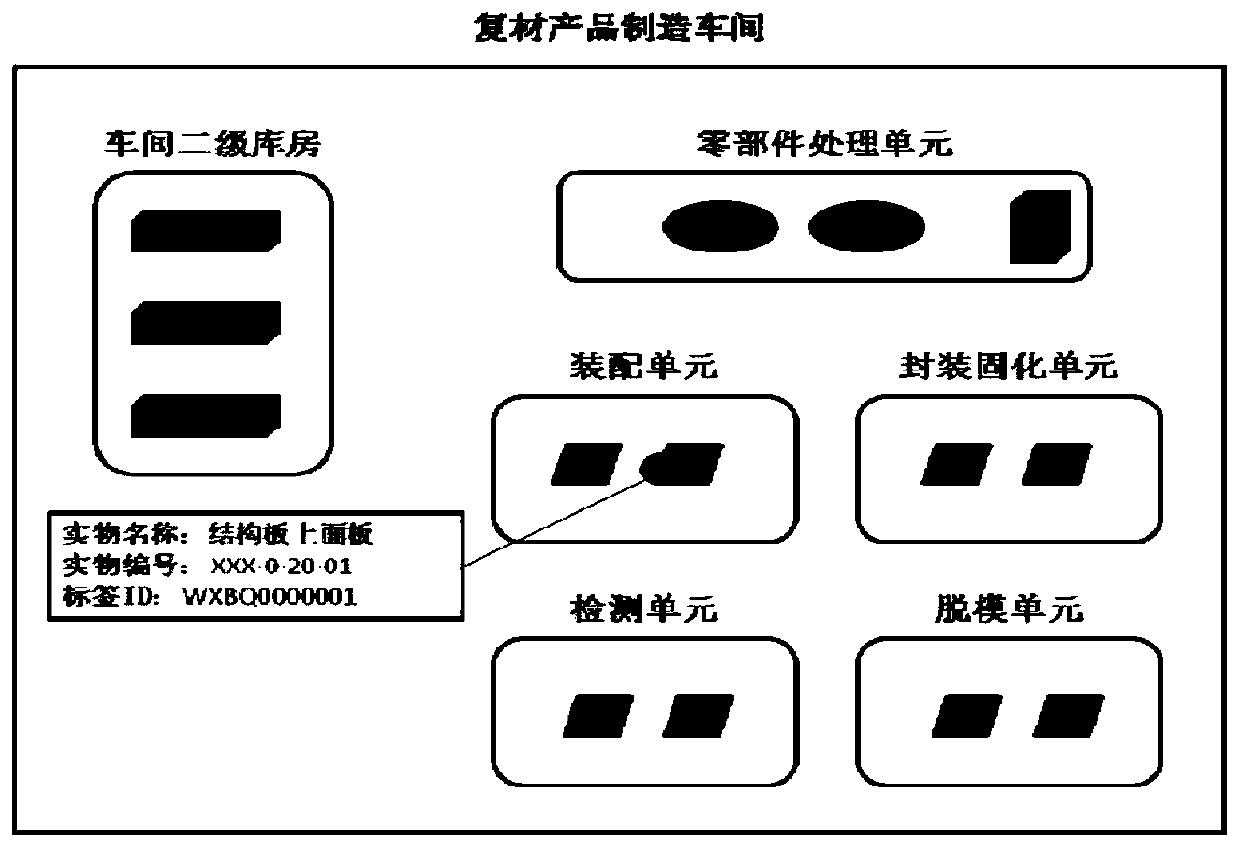

[0028] The first step is to use the workshop site visual modeling module (1) to design a workshop background interface for the composite product manufacturing workshop to display the physical tracking effect of the structural plate during the composite processing process. First, use the workshop modeling element management function to define the static area and equipment in the composite product manufacturing workshop. use Graphical symbols, set length and width dimensions, coordinates, and the Chinese name above the graphic is the composite product manufacturing workshop, indicating the entire scope of the composite product manufacturing workshop; embedded Graphical symbols, set the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com