Waterproof cable tension sensor and inspection platform

A tension sensor and waterproof cable technology, applied in the sensor field, can solve the problems affecting the measurement accuracy of the Hall sensor, the high price of the Hall sensor, and the short sensing distance, so as to reduce the manufacturing cost and the difficulty of the assembly process, the cost is low, and the sensing distance is reduced. long distance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

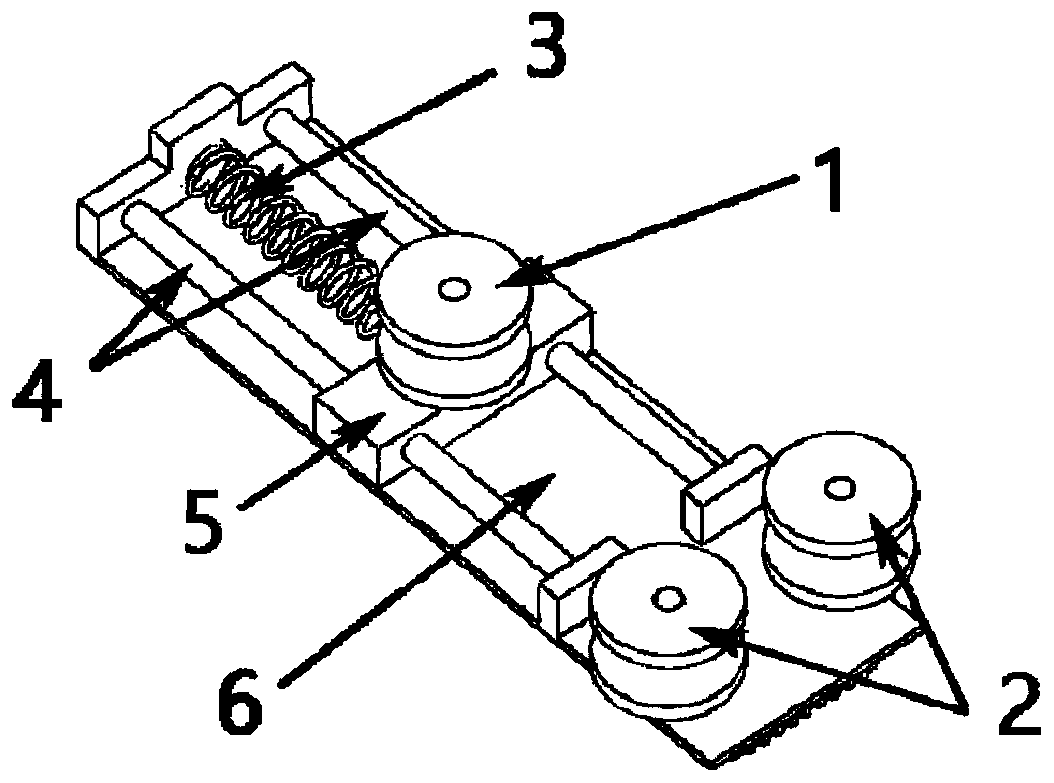

[0028] This embodiment provides a waterproof cable tension sensor, including a fixed seat 6, a slide rail 4 mechanism, a cable tension acquisition mechanism and a sensing mechanism, wherein:

[0029] The upper part of the fixing base 6 is fixed with a sliding rail 4 mechanism, the sliding rail 4 mechanism includes a slider 5, the cable tension acquisition mechanism acquires the cable tension, and the cable tension acquisition mechanism is fixedly connected with the slider 5, so The sliding rail 4 mechanism has a displacement to move the slider 5 along the cable tension direction, the bottom of the slider 5 is equipped with a magnet, and the distance the slider 5 moves is proportional to the cable tension;

[0030] A sensing structure is fixedly installed on the bottom of the fixing base 6 , and the sensing mechanism obtains the position of the slider 5 by acquiring the magnetic field of the magnet, and outputs the cable tension according to the slider 5 .

[0031] The sliding ...

Embodiment 2

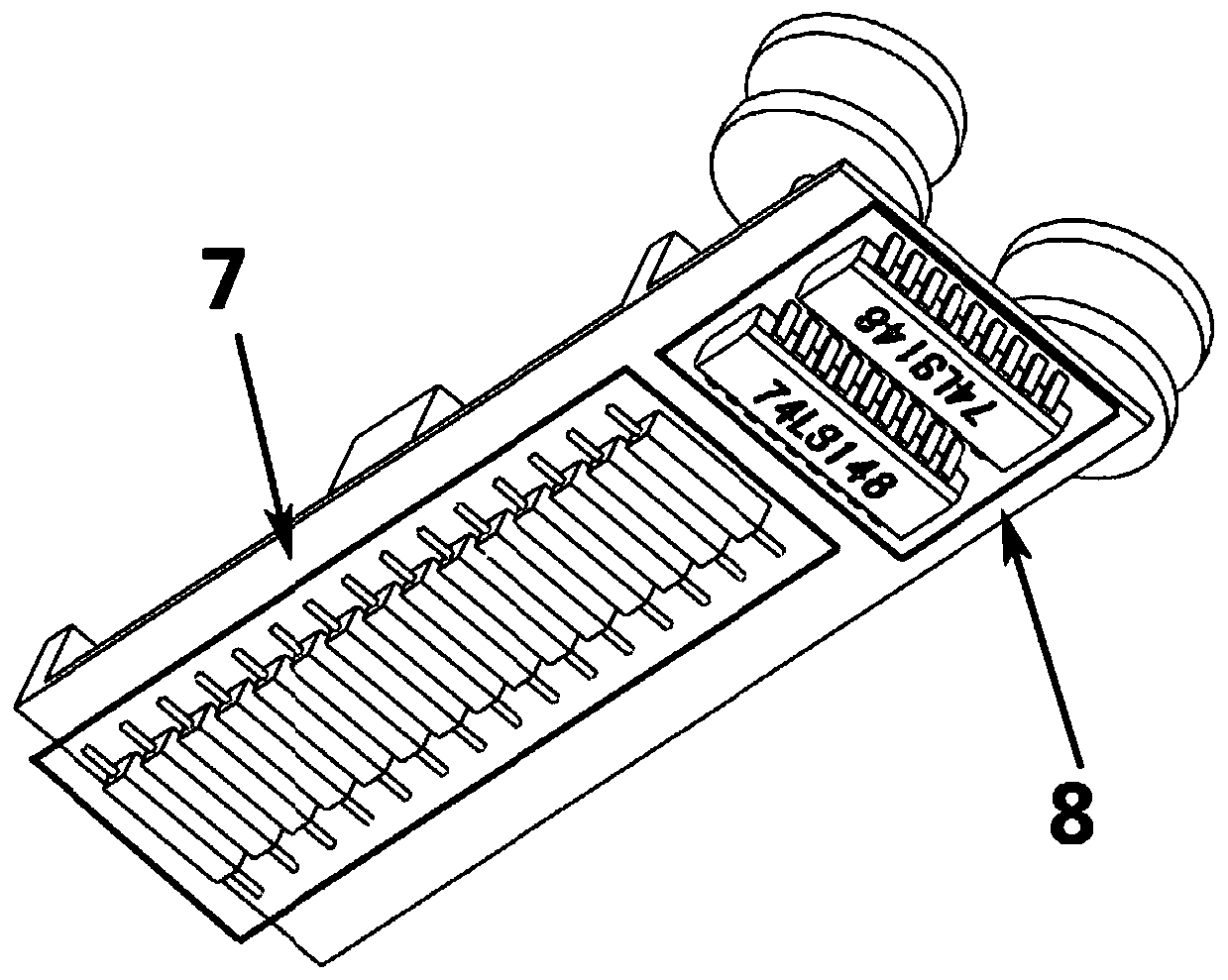

[0038] This embodiment provides an inspection platform, including the waterproof cable tension sensor described in Embodiment 1.

[0039] The same or similar reference numbers correspond to the same or similar parts;

[0040] The terms describing the positional relationship in the accompanying drawings are only used for exemplary illustration, and should not be construed as a limitation on this patent;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com