A kind of lithium battery waterproof method

A lithium battery, waterproof shell technology, applied in the direction of lithium battery, battery isolation from its environment, non-aqueous electrolyte battery, etc., can solve the problems of battery damage, lithium battery damage, access to the interior of the battery, etc., to improve installation and waterproof ability. , good waterproof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

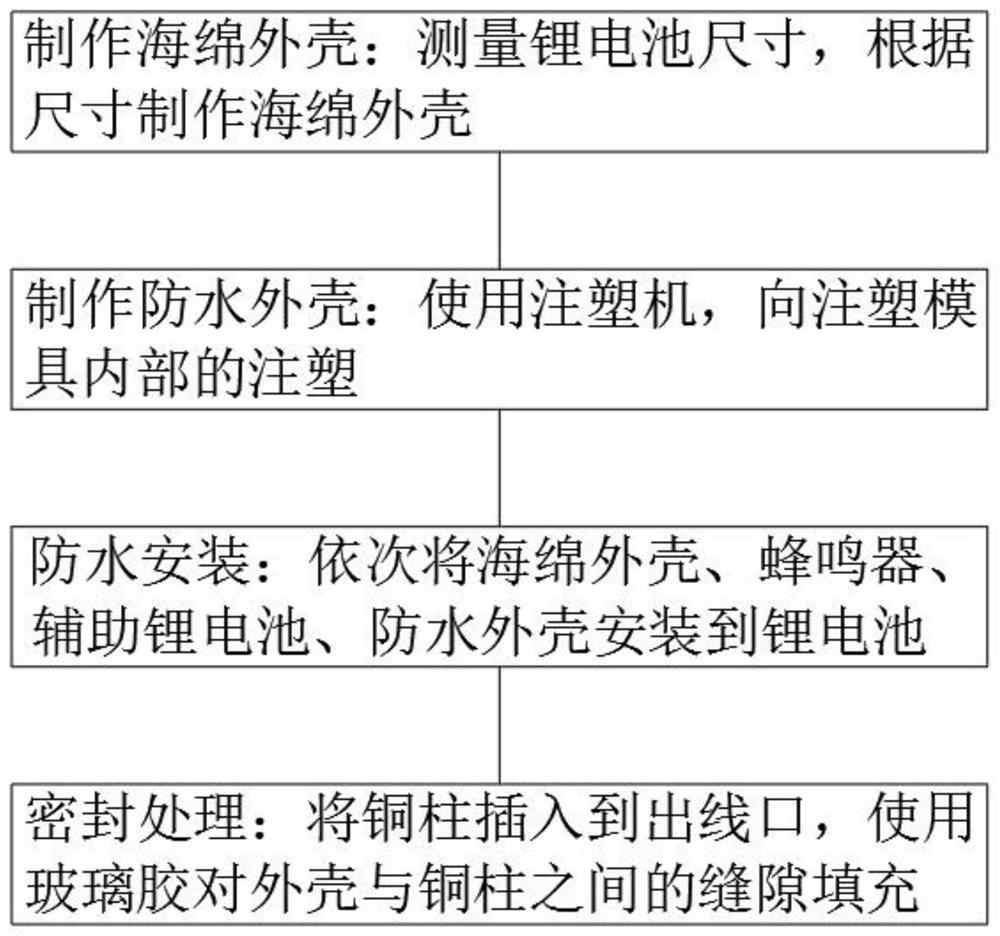

[0027] like figure 1 shown, including the following steps:

[0028] (1) Making the sponge shell: measure the size of the lithium battery, and make the sponge shell according to the size. Making the sponge shell includes the following steps:

[0029] (1.1), take 100mL distilled water, and mix with crosslinking agent, foaming agent, plasticizer to obtain solution, add konjac gum powder, dissolve in the above solution, stir, foaming agent is NaHCO 3 , the amount of foaming agent is 2.80g / L, and the crosslinking agent is Na 2 CO 3 , the amount of crosslinking agent is 4.0g / L, plasticizer is C 24 h 38 o 4 , the plasticizer is 10.0g / L;

[0030] (1.2), pour the mixed solution after stirring into the foaming mold to heat up, foam and shape, the foaming mold is divided into inner and outer layers, the inner layer is the same size as the lithium battery shell, and the outer layer The distance is 1.2mm, and the heating temperature is 100°C;

[0031] (2) Making the waterproof casi...

Embodiment 2

[0035] like figure 1 shown, including the following steps:

[0036] (1) Making the sponge shell: measure the size of the lithium battery, and make the sponge shell according to the size. Making the sponge shell includes the following steps:

[0037] (1.1), take 100mL distilled water, and mix with crosslinking agent, foaming agent, plasticizer to obtain solution, add konjac gum powder, dissolve in the above solution, stir, foaming agent is NaHCO 3 , the amount of foaming agent is 2.80g / L, and the crosslinking agent is Na 2 CO 3 , the amount of crosslinking agent is 4.0g / L, plasticizer is C 24 h 38 o 4 , the plasticizer is 10.0g / L;

[0038] (1.2), pour the mixed solution after stirring into the foaming mold to heat up, foam and shape, the foaming mold is divided into inner and outer layers, the inner layer is the same size as the lithium battery shell, and the outer layer The distance is 2.0mm, and the heating temperature is 100°C;

[0039] (2) Making the waterproof casi...

Embodiment 3

[0043] like figure 1 shown, including the following steps:

[0044](1) Making the sponge shell: measure the size of the lithium battery, and make the sponge shell according to the size. Making the sponge shell includes the following steps:

[0045] (1.1), take 100mL distilled water, and mix with crosslinking agent, foaming agent, plasticizer to obtain solution, add konjac gum powder, dissolve in the above solution, stir, foaming agent is NaHCO 3 , the amount of foaming agent is 2.80g / L, and the crosslinking agent is Na 2 CO 3 , the amount of crosslinking agent is 4.0g / L, plasticizer is C 24 h 38 o 4 , the plasticizer is 10.0g / L;

[0046] (1.2), pour the mixed solution after stirring into the foaming mold to heat up, foam and shape, the foaming mold is divided into inner and outer layers, the inner layer is the same size as the lithium battery shell, and the outer layer The distance is 2.5mm, and the heating temperature is 100°C;

[0047] (2) Making the waterproof casin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com