Air purifier convenient for filter screen replacement

An air purifier, a technology that is easy to replace, applied in the direction of suction filters, vacuum cleaners, separation methods, etc., can solve the problems of inconvenient replacement of filter elements and high replacement costs, achieve good air purification effect, simple structure, and reduce production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

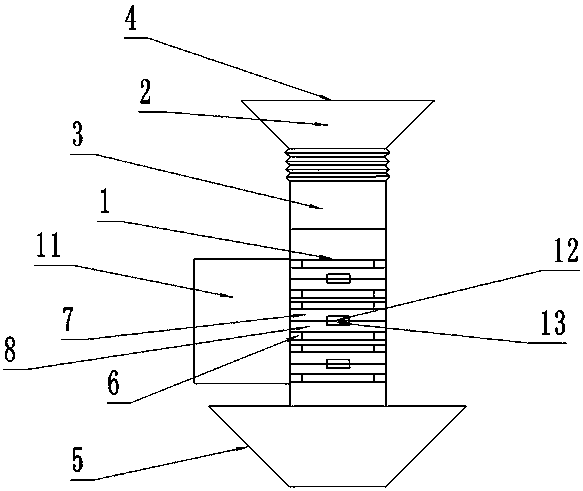

[0024] Such as figure 1 , figure 2 and image 3 As shown, an air purifier for convenient replacement of the filter screen includes a housing 1, an air inlet, a filter device, a fan 3 and an air outlet, the air inlet is located at one end of the housing 1, and the air outlet is located at the The other end of the casing 1 is a cuboid, the filter device and the fan 3 are respectively arranged in the casing 1, the fan 3 is fixed on the inner wall of the casing 1 near the air outlet side, and the fan 3 and the The power cord is connected, and the filter device is close to the air inlet side. The filter device includes a frame fixing part, a first frame body 7, a second frame body 8, blades 9 and a third filter screen 10, and the frame body is fixed fixed on the opposite sides of the inner wall of the housing 1, one side of the first frame body 7 and the second frame body 8 is connected by a rotating shaft, and the contact surfaces of the first frame body 7 and the second frame ...

Embodiment 2

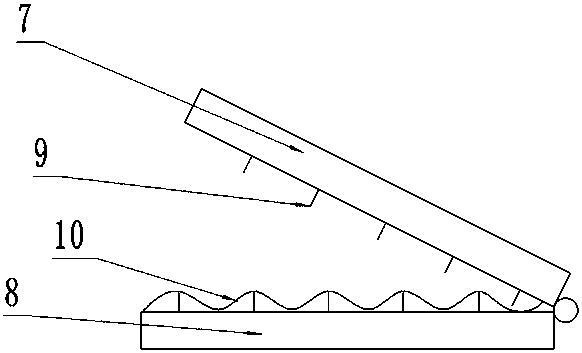

[0030] Such as figure 2 As shown, the shape and size of the first frame body 7 and the second frame body 8 are the same, the blades 9 in the first frame body 7 are parallel to the blades 9 in the second frame body 8, and the blades 9 of the blades 9 The thickness is greater than the thickness of the first frame body 7 and not more than twice the thickness of the first frame body 7 .

[0031] After putting into the third filter screen 10, close the first frame body 7 and the second frame body 8, and the excess part of the blade 9 relative to the thickness of the first frame body 7 and the second frame body 8 can make the third filter screen 10 It forms a wavy shape, which can be well fixed between the first frame body 7 and the second frame body 8, and increases the area where the air to be purified passes through the third filter screen 10, thereby increasing the air purification effect. The third filter screen The net 10 is a flexible composite filter.

Embodiment 3

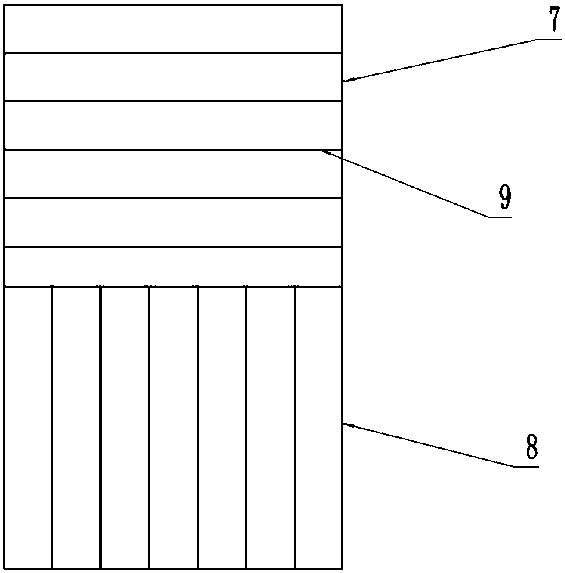

[0033] Such as image 3 As shown, the shape and size of the first frame body 7 and the second frame body 8 are the same, the blades 9 in the first frame body 7 are perpendicular to the blades 9 in the second frame body 8, and the blades 9 of the blades 9 The thickness is equal to the thickness of the first frame body 7 .

[0034]The blades 9 in the first frame body 7 are perpendicular to the blades 9 in the second frame body 8, which can better fix the third filter screen 10, so that the third filter screen 10 can be placed relatively flatly between the first frame body 7 and the second frame body 8. Between the second frames 8, the filter screen mainly placed is a rigid filter screen.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com