Plastic granulator

A granulator and plastic technology, applied in the field of mechanical equipment, can solve the problems of large equipment volume and increase resource consumption, and achieve the effect of improving grinding efficiency and broad market prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

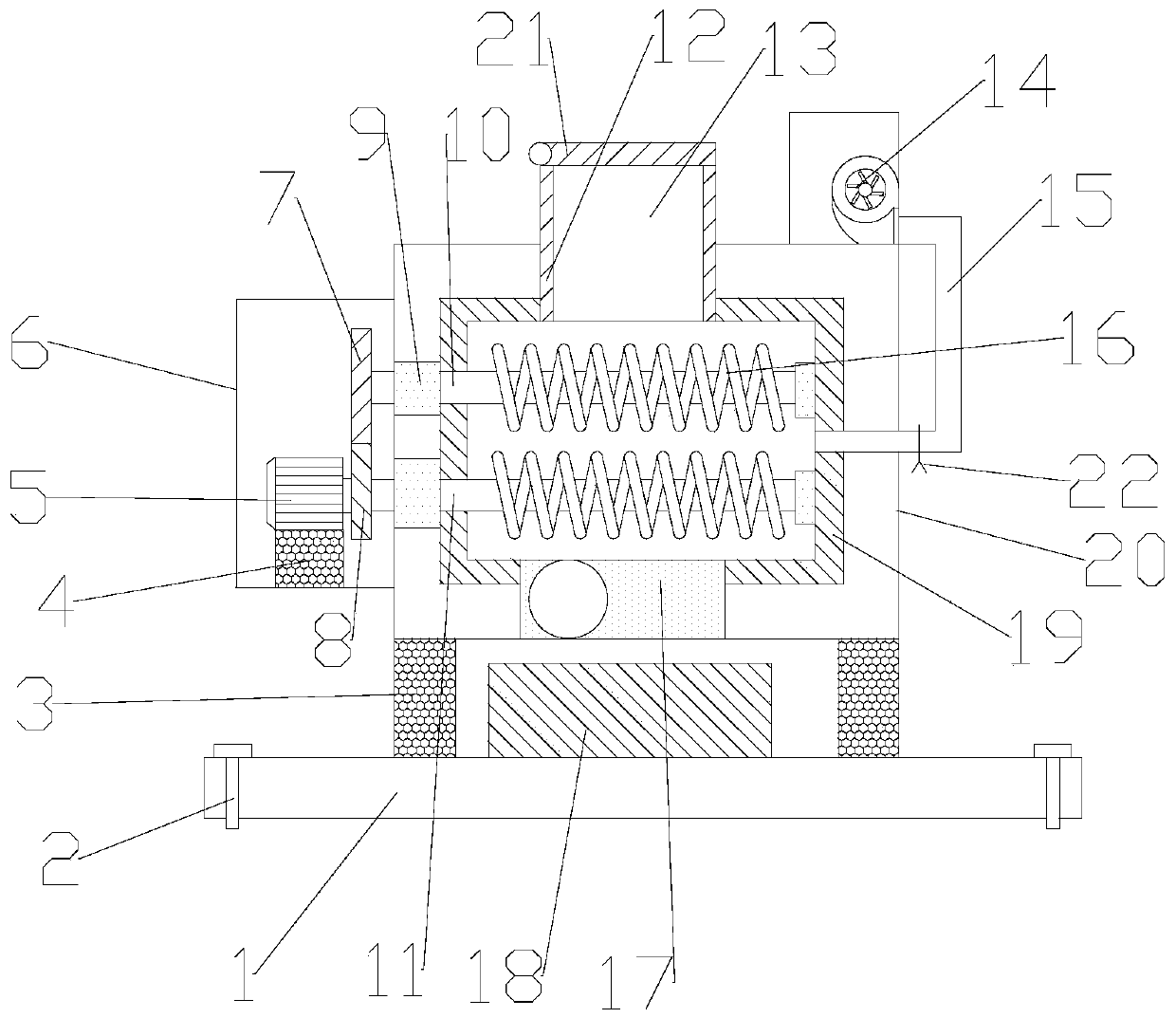

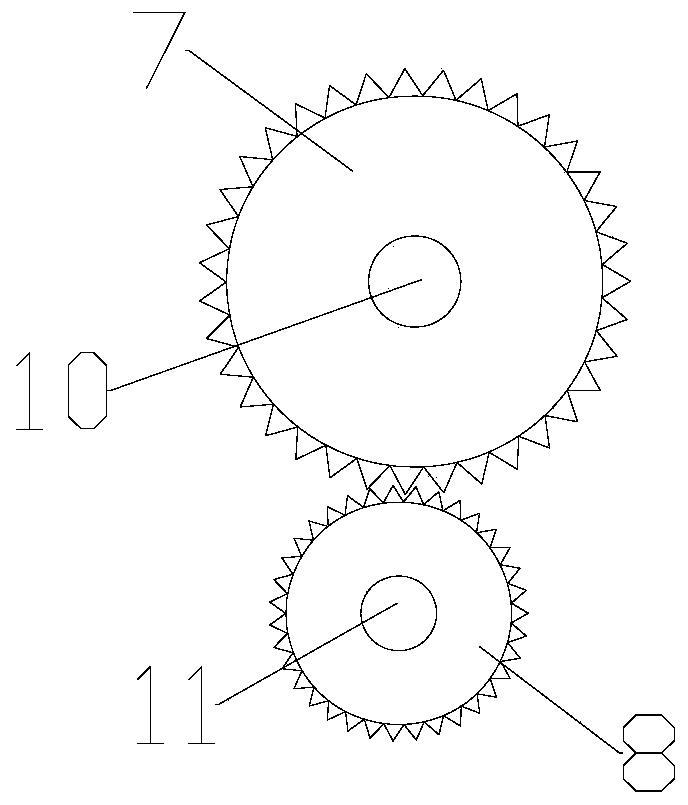

[0022] see figure 1 , in an embodiment of the present invention, a plastic granulator includes a mounting base 1 and a granulator main body 20, the lower end of the granulator main body 20 is connected to the upper end of the mounting base 1 through a bracket 3;

[0023] In order to solve the problem that the granulator increases resource consumption due to the use of multiple motor drives and leads to a larger volume of equipment, the upper end of the granulator main body 20 is provided with a feed port 13, and the inner wall of the feed port 13 is A heating plate 12 for preheating materials is provided, the heating plate 12 is a ceramic heating plate, the left side of the main body 20 of the granulator is provided with a protective shell 6 for installing the driving motor 5, and the lower end of the driving motor 5 is provided with Fixed block 4, the output end of described driving motor 5 is connected with driving gear 8, and the upper end of described driving gear 8 is pro...

Embodiment 2

[0028] see Figure 1-2 , in an embodiment of the present invention, a plastic granulator includes a mounting base 1 and a granulator main body 20, the lower end of the granulator main body 20 is connected to the upper end of the mounting base 1 through a bracket 3;

[0029] In order to solve the problem that the granulator increases resource consumption due to the use of multiple motor drives and leads to a larger volume of equipment, the upper end of the granulator main body 20 is provided with a feed port 13, and the inner wall of the feed port 13 is A heating plate 12 for preheating materials is provided, the heating plate 12 is a ceramic heating plate, the left side of the main body 20 of the granulator is provided with a protective shell 6 for installing the driving motor 5, and the lower end of the driving motor 5 is provided with Fixed block 4, the output end of described driving motor 5 is connected with driving gear 8, and the upper end of described driving gear 8 is ...

Embodiment 3

[0039] Please also refer to figure 1 and figure 2 As shown, in the embodiment of the present invention, a plastic granulator includes a mounting base 1 and a granulator main body 20, the lower end of the granulator main body 20 is connected to the upper end of the mounting base 1 through a bracket 3;

[0040] In order to solve the problem that the granulator increases resource consumption due to the use of multiple motor drives and leads to a larger volume of equipment, the upper end of the granulator main body 20 is provided with a feed port 13, and the inner wall of the feed port 13 is A heating plate 12 for preheating materials is provided, a protective shell 6 for installing a drive motor 5 is provided on the left side of the main body 20 of the granulator, a fixed block 4 is provided at the lower end of the drive motor 5, and the drive motor 5 The output end is connected with a driving gear 8, and the upper end of the driving gear 8 is provided with a driven gear 7 mesh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com