An automatic two-way explosion-proof equipment for underground coal mines and its application method

An automatic and coal mine technology, applied in mining equipment, earthwork drilling, safety devices, etc., can solve the problems of high difficulty, poor reliability, increased cost and workload, etc., and achieve the requirements of reducing difficulty, ensuring safety, and increasing explosion-proof area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to clearly illustrate the technical features of the solution, the solution will be described below through specific implementation modes.

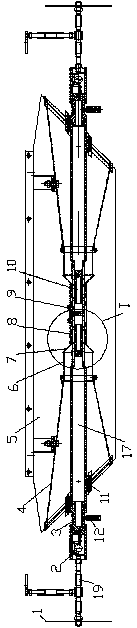

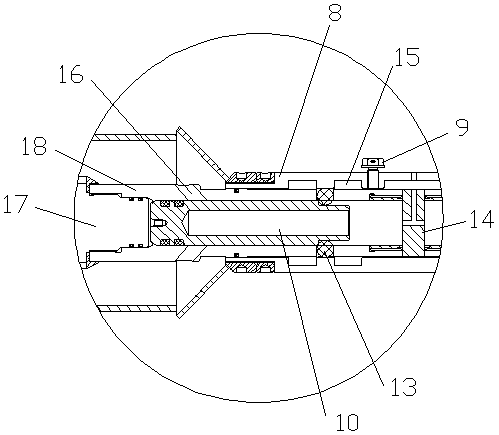

[0029] Such as figure 1 Shown is an automatic two-way explosion-proof equipment for underground coal mines, including a sleeve 8 with an outer cover 4 sealed at both ends and a connecting joint 14 slidingly connected in the sleeve. The structure of this equipment is related to the connecting joint. Axisymmetric.

[0030] The two sides of the connection coupler 14 are fixedly connected with the piston cylinder 18, the high-pressure chamber assembly and the push rod 19 in turn, and the connection coupler is provided with an air outlet channel that is connected to the piston cylinders on both sides, and the sleeve is provided with an outlet channel that communicates with the air outlet channel. The air outlet hole communicates the piston barrel with the outside world through the air outlet hole and the air outlet channel. A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com