Jig device for motor automatic tooling

A tooling and jig technology, applied in the field of micro DC motor assembly equipment, can solve problems such as low precision, low processing efficiency, poor tooling flow stiffness, etc., to achieve the effect of optimizing the work process and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

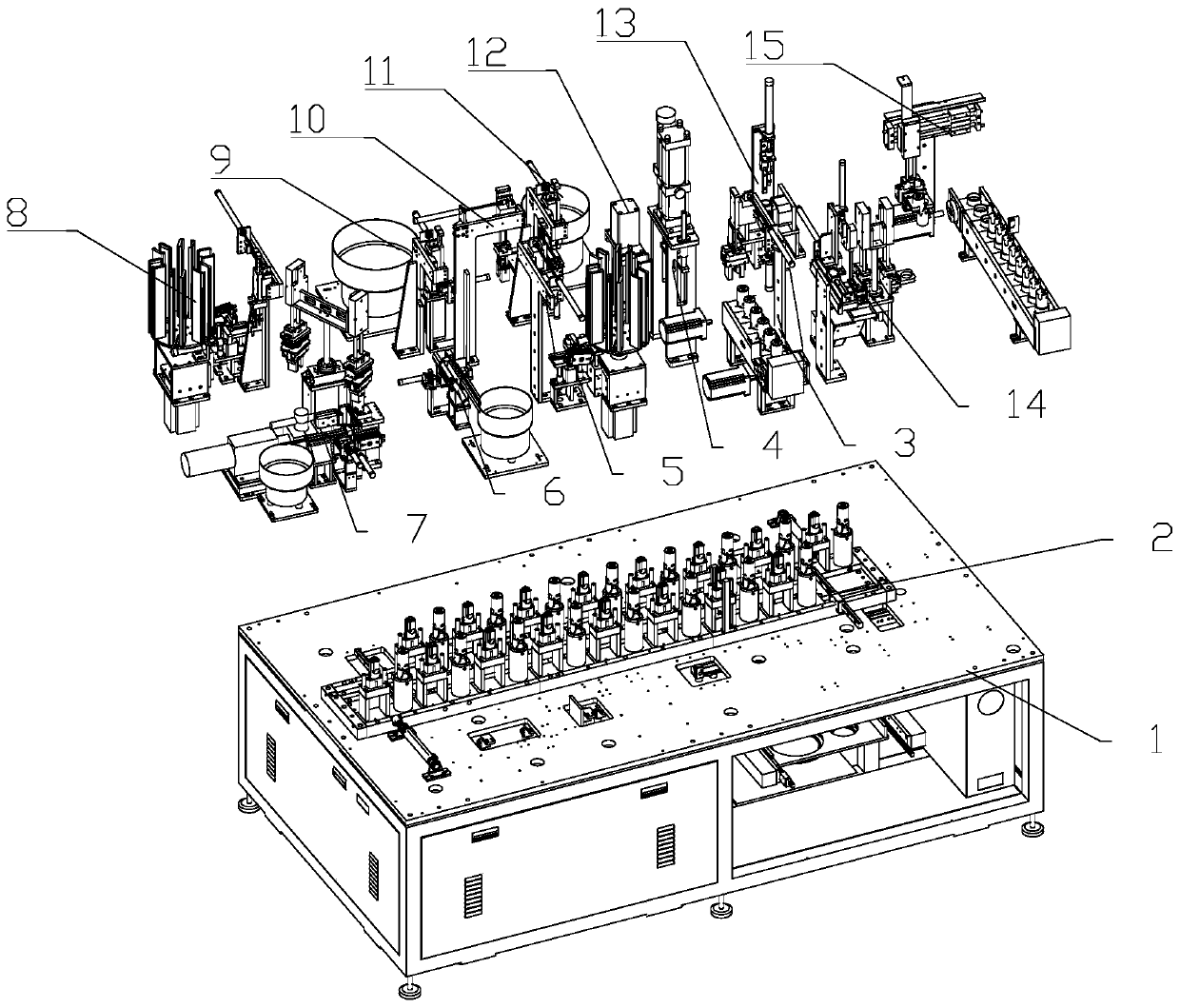

[0033] Such as figure 1 As shown, the described automatic assembly equipment for micro DC motors is characterized in that it includes a frame (1), a tooling circulation device (2) installed on the frame (1), and a casing feeding device (3) , Shell riveting device (4), first magnetic tile feeding device (5), shrapnel feeding device (6), ground wire welding device (7), second magnetic tile feeding device (8), bearing pressure Spring feeding device (9), casing transfer device (10), bearing feeding device (11), magnetic tile pressing device (12), magnetic tile magnetizing device (13), glue coating device (14) and The finished product unloading device (15); the tooling circulation device (2) is installed in the center of the casing feeding device (3), and is used to place and transport the casing to be assembled. There is a jig of the tooling circulation device (2) Two different jigs, one fixture has only one casing; the casing feeding device (3) is located next to the tooling cir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com