Clothes zipper

A zipper and clothing technology, applied in the field of clothing zipper, can solve the problems of inability to replace, inconvenient to use, damaged zipper, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Such as Figure 5-6 Shown, a kind of clothes zipper comprises slider 4, and slider 4 comprises locking part 8 and pull handle 19, and locking part 8 comprises main body and arc-shaped part 11, and one end outside the main body of locking part 8 is fixed with a number Fixed block 10, one end of arc-shaped part 11 is connected No. 1 fixed block 10 by connecting pin 12, and the other end of arc-shaped part 11 is free end, and No. 2 fixed block 13 is fixed on the inner wall of this end, No. 2 fixed block 13 A No. 1 compression spring 14 is fixed at an end away from the arc-shaped member 11, and a clamping block 16 is fixed at an end of the No. 1 compression spring 14 away from the No. 1 fixed block 10, and an end near the No. 1 fixed block 10 on the locking member 8 is fixed with a The connecting plate 15 is provided with a connecting hole, and the fastening block 16 is disposed through the connecting hole.

[0028] In this embodiment, by connecting the main body of the ar...

Embodiment 2

[0030] Such as Figure 5-6 As shown, a No. 2 compression spring 17 is fixed on the inner wall of the arc 11 close to the No. 1 fixed block 10, and a locking rod 18 is fixed on the end of the No. 2 compression spring 17 away from the arc 11. An insertion hole is opened on a side of the main body close to the arc-shaped member 11 , and a locking rod 18 is disposed through the insertion hole; a baffle is fixed between the locking rod 18 and the connecting plate 15 .

[0031] In this embodiment, No. 2 compression spring 17 is set on the inner wall of arc-shaped part 11, and locking rod 18 is set on No. 2 compression spring 17, and then a socket is opened on the main body of locking part 8, so that the lock can be The tightening rod 18 extends into the chain tooth groove 9, and when the slide fastener is used again, the locking rod 18 can lock the chain tooth 3, so as to prevent the slider from sliding down after use, thereby affecting the use of the slide fastener.

Embodiment 3

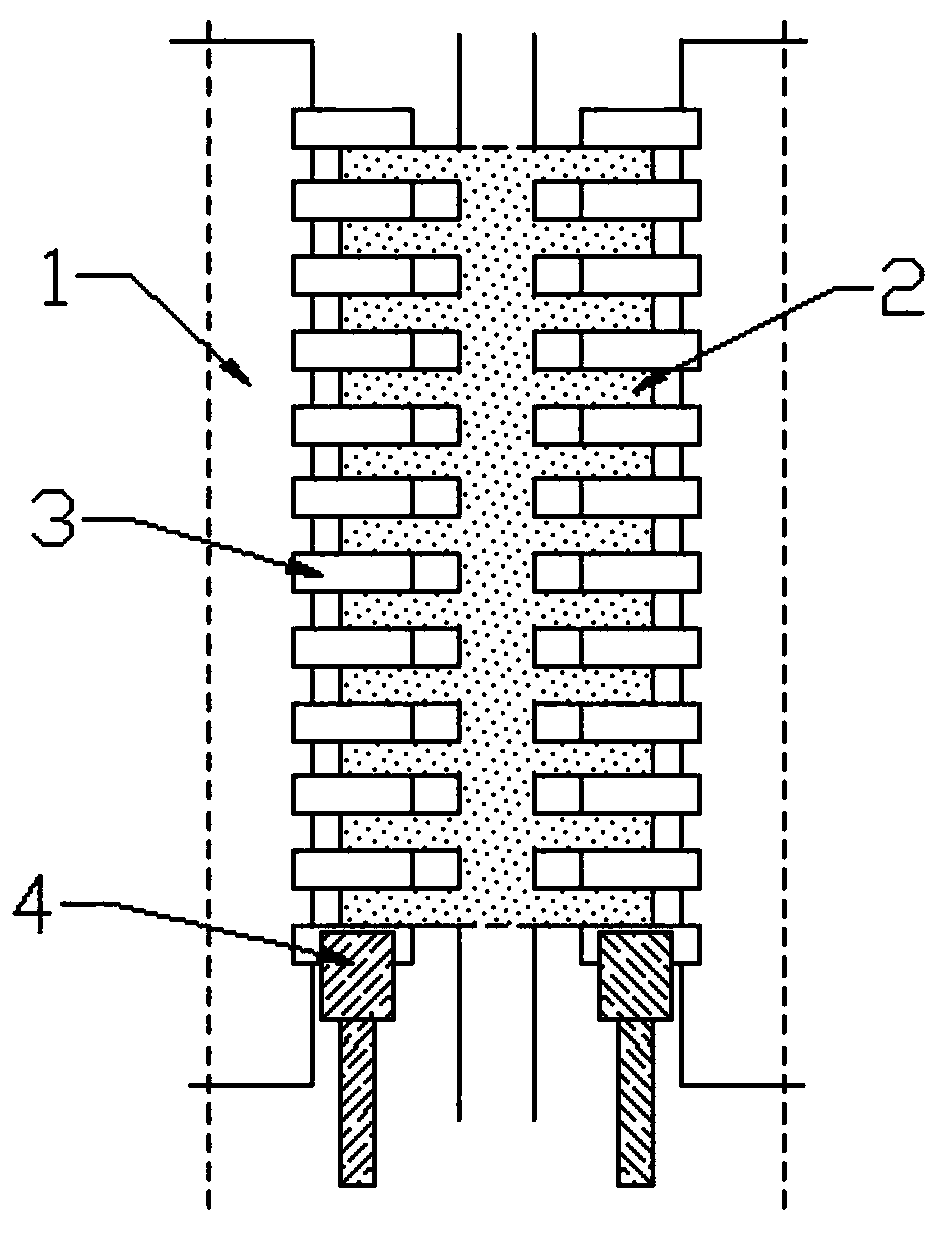

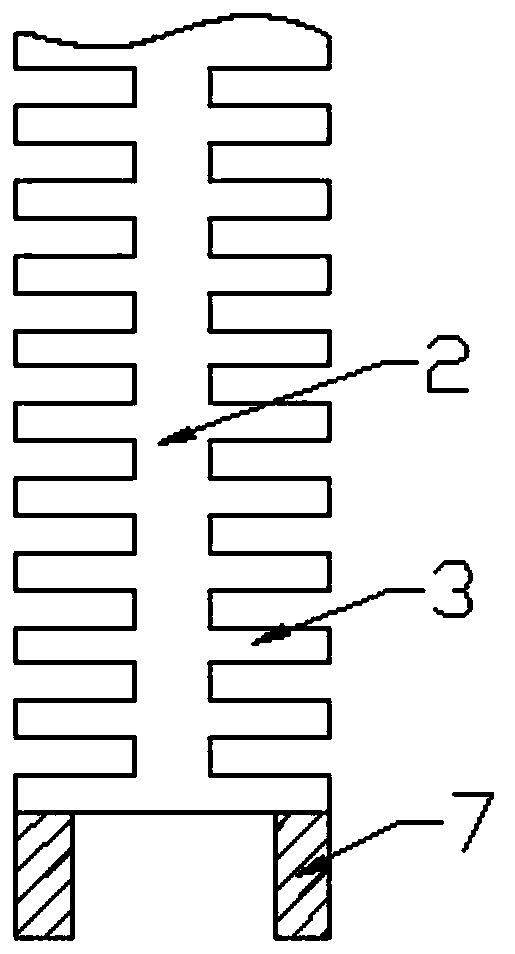

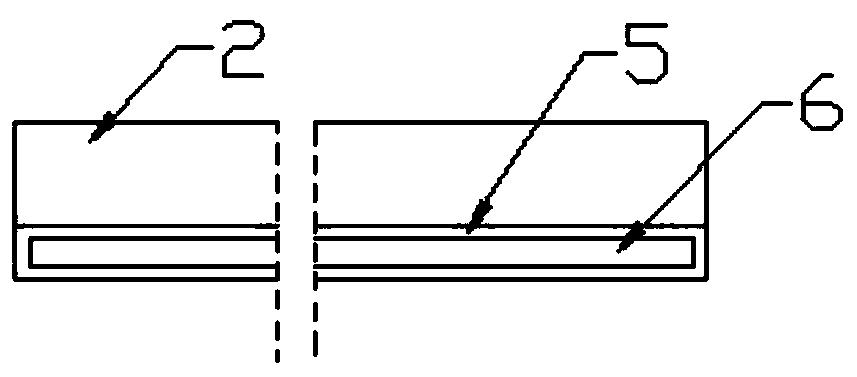

[0033] Such as Figure 1-4 As shown, two sliders 4 are respectively connected to the chain teeth 3 on both sides of the detachable part 2, the back of the detachable part 2 is fixed with a fixed piece 5, and the cross section of the fixed piece 5 is provided with a chain belt groove 6, The chain belt 1 passes through the chain belt groove 6; the chain elements 3 on both sides of the detachable part 2 are respectively connected to the other half of the chain elements 3 corresponding to it, and the chain elements 3 on this side are all fixed on the chain belt 1; The top and bottom ends of the teeth 3 are respectively fixed with an upper stop and a lower stop 7, and the main body of the locking member 8 is provided with a chain tooth groove 9.

[0034] In this embodiment, by setting the detachable part 2 and setting the chain elements 3 on both sides of the detachable part 2, other chain elements 3 can be connected through the chain elements 3 on both sides, so that the slide fas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com