Connecting pipe for novel fire-fighting equipment

A fire-fighting equipment and a new type of technology, applied in the field of connecting pipes for new-type fire-fighting equipment, can solve the problems that the fire fighting is not as timely as the fixed foam fire extinguishing system, the foam generator is easily damaged, and the foam loss is large, so as to maintain rigidity and save costs And materials, the effect of speeding up the foaming speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

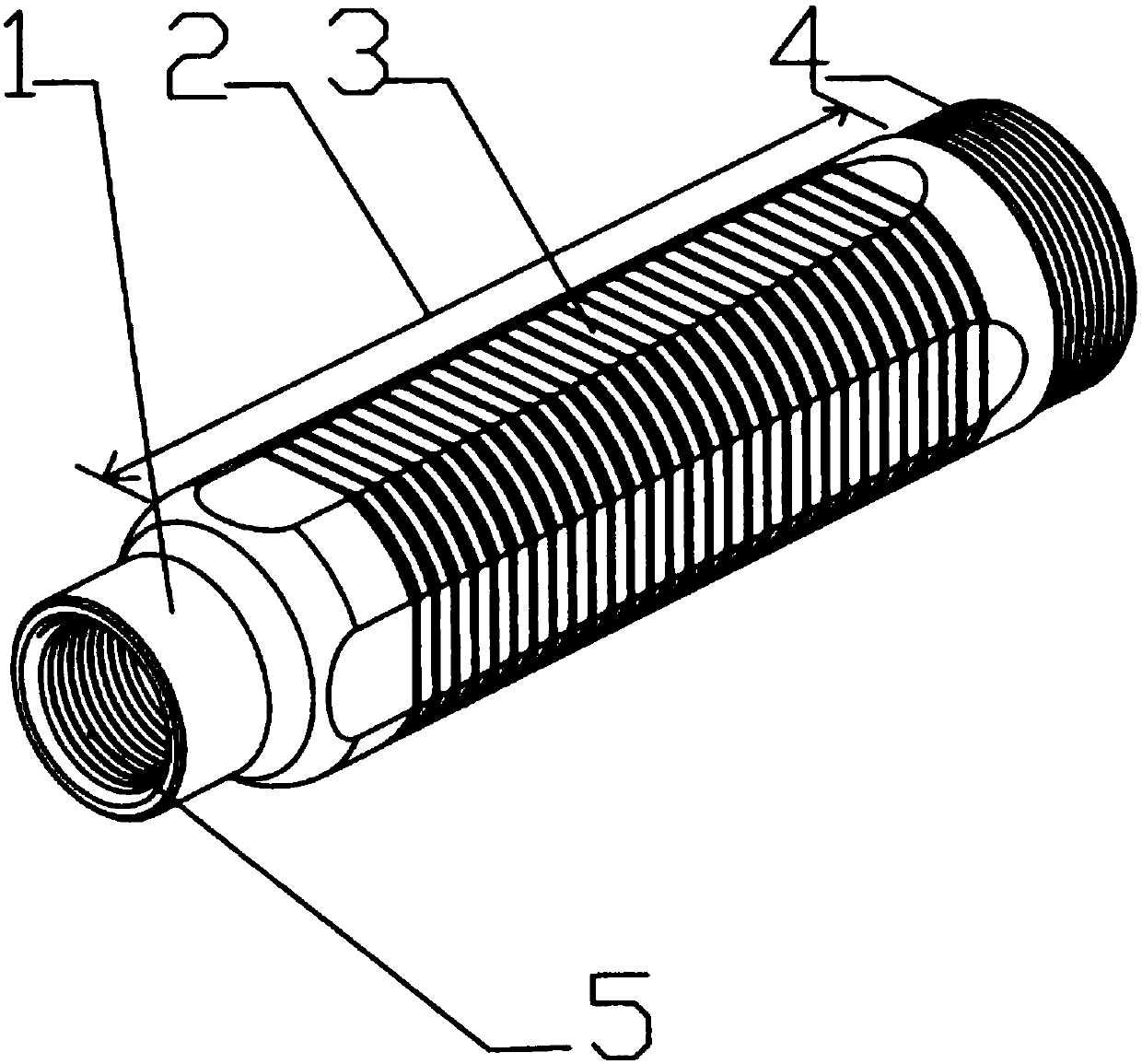

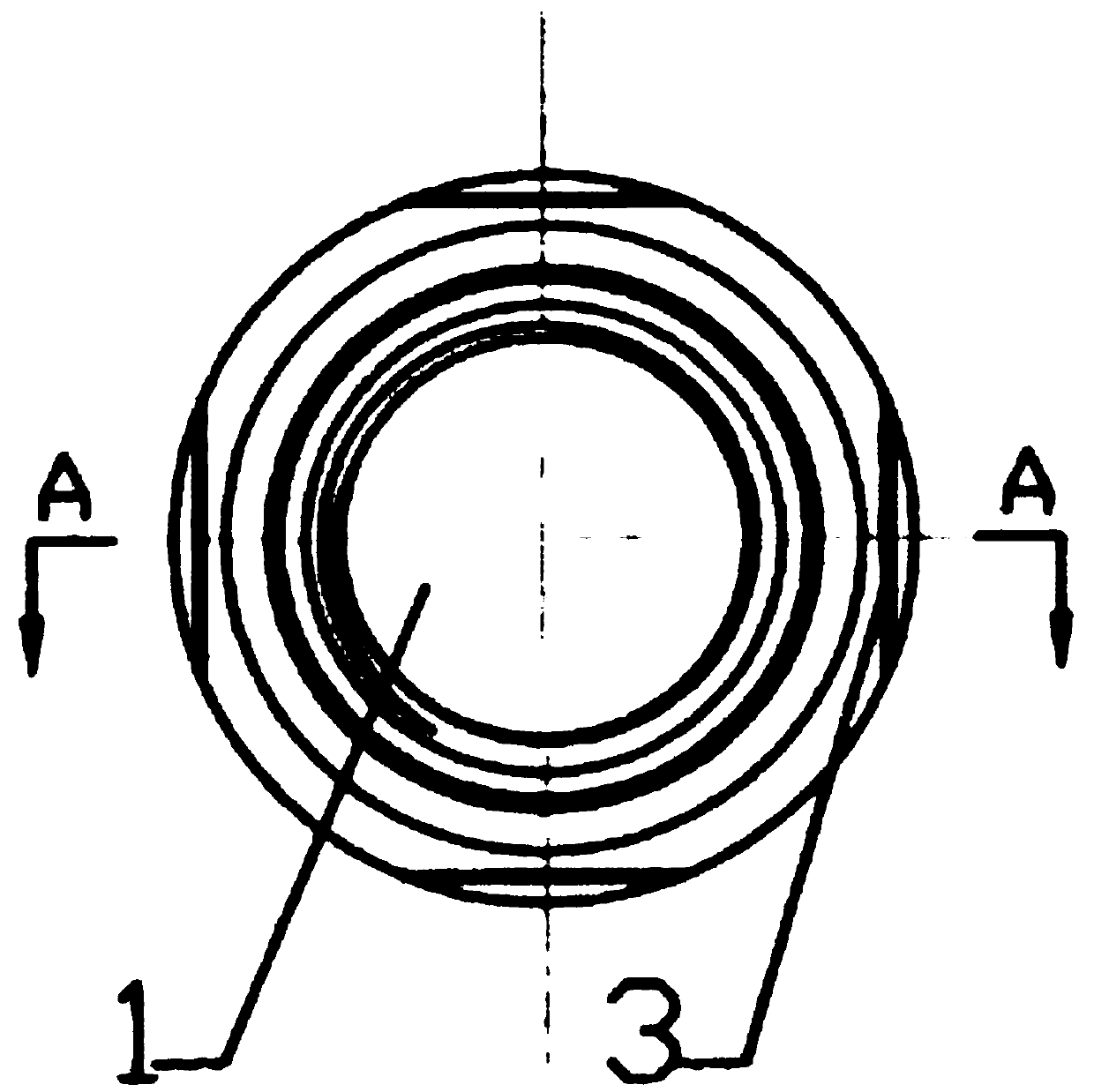

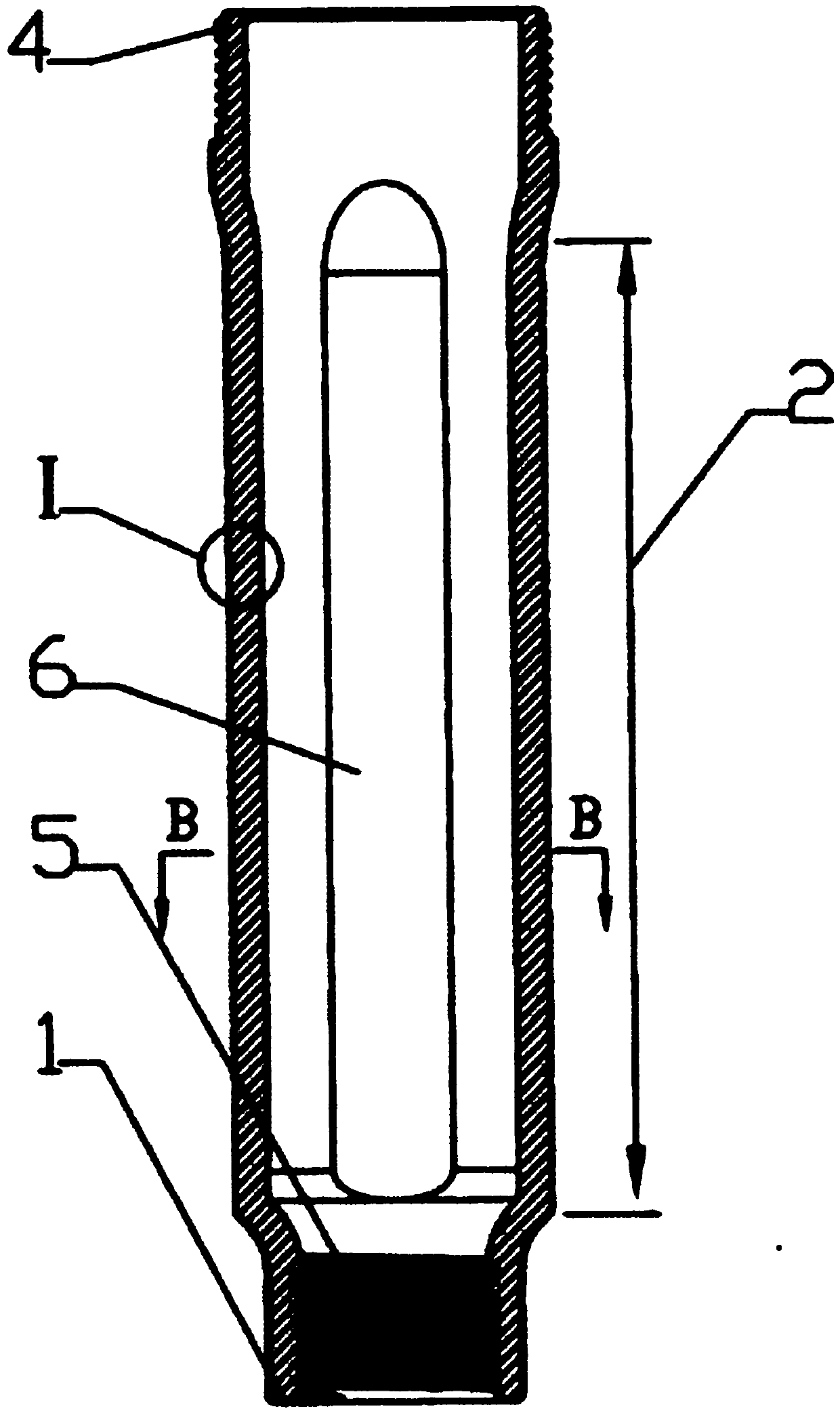

[0022] Such as Figure 1-5 As shown, a novel fire-fighting equipment connecting pipe of the present embodiment is a metal straight-through pipe, which is characterized in that one end of the connecting pipe has an external thread 4 connected to the injector to become an inlet, and the other end has an internal thread 5 and a nozzle Or the injection hose is connected to become the injection port 1, and the main part of the connecting pipe 2 has the same diameter as the inlet, and the conical surface between the spraying port 1 and the main part 2 shrinks; The plane 3 makes the position corresponding to the plane 3 of the outer wall protrude on the inner wall, and the concave surface 7 and the convex surface 6 uniformly staggered along the circumference are formed on the inner wall; a row of annular reinforcing ribs 2a is arranged in the middle of the outer wall of the connecting pipe.

[0023] The reinforcing rib 2a is on the outer wall of the connecting pipe, which can strengt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com