Golf putter head and putter

A golf and club head technology, applied in the field of golf putter heads and putters, can solve problems such as low forgiveness and affect golf skills, and achieve the effects of improving forgiveness, reducing variance and improving stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

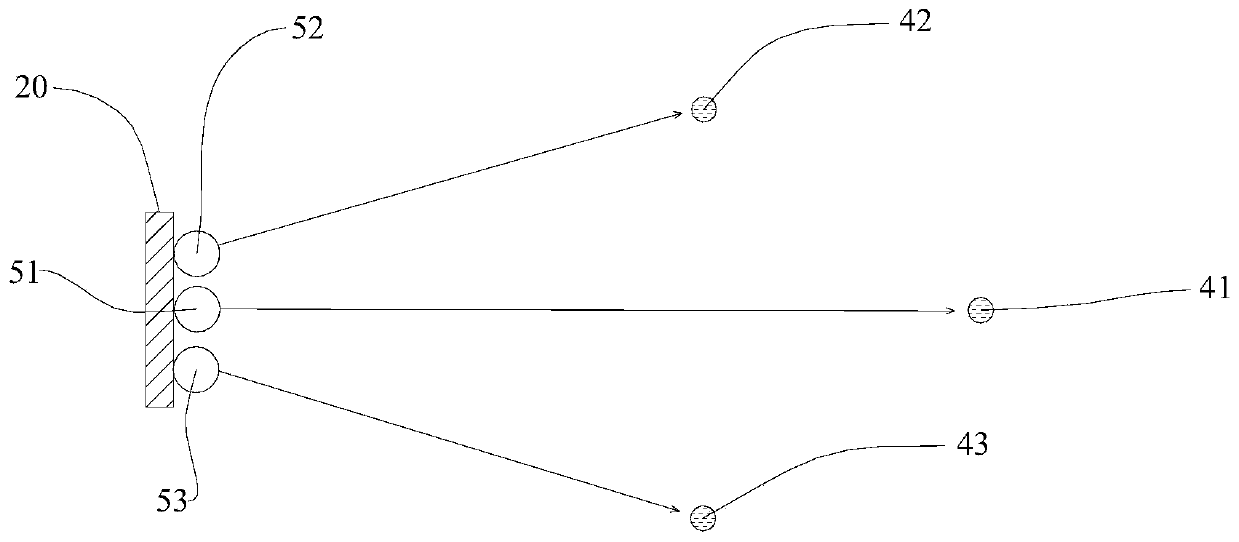

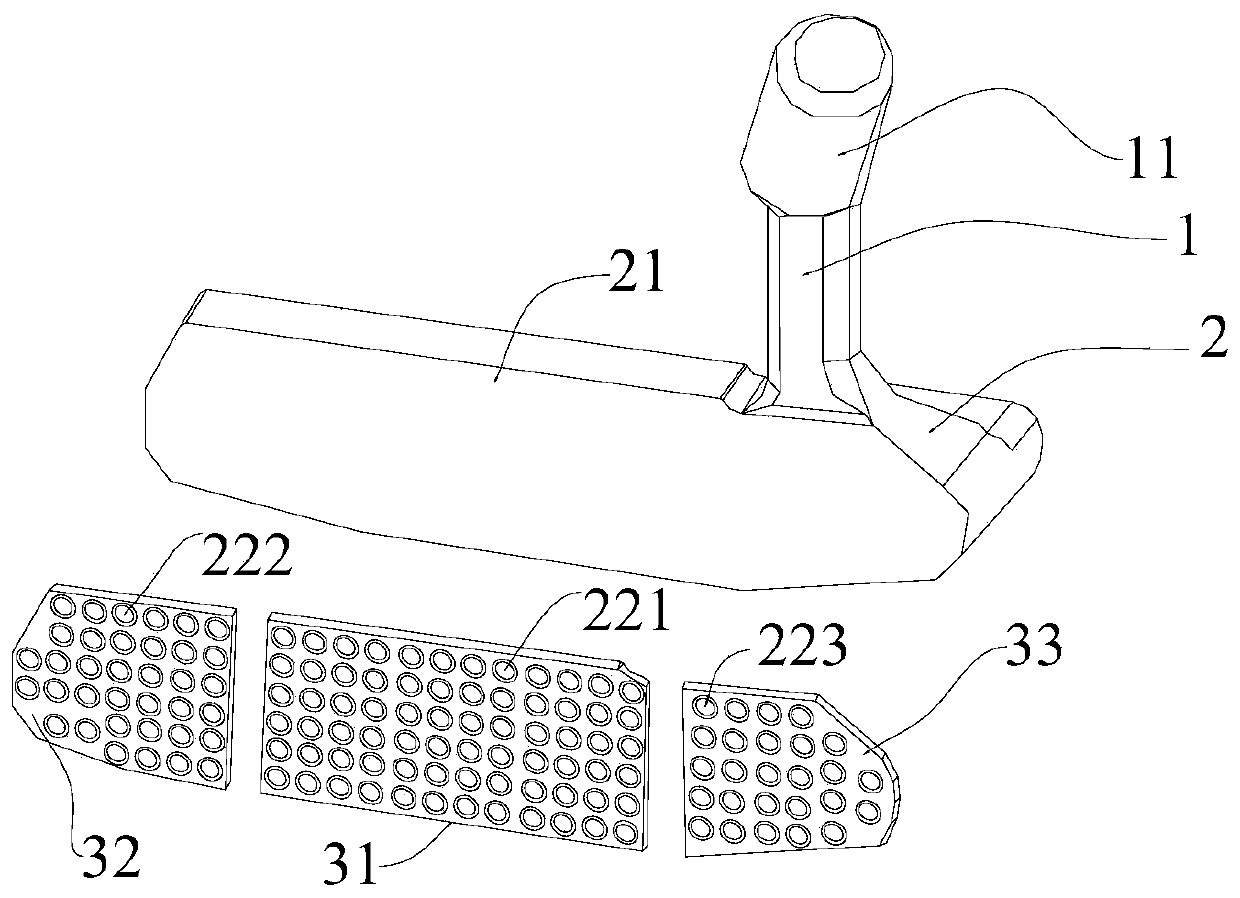

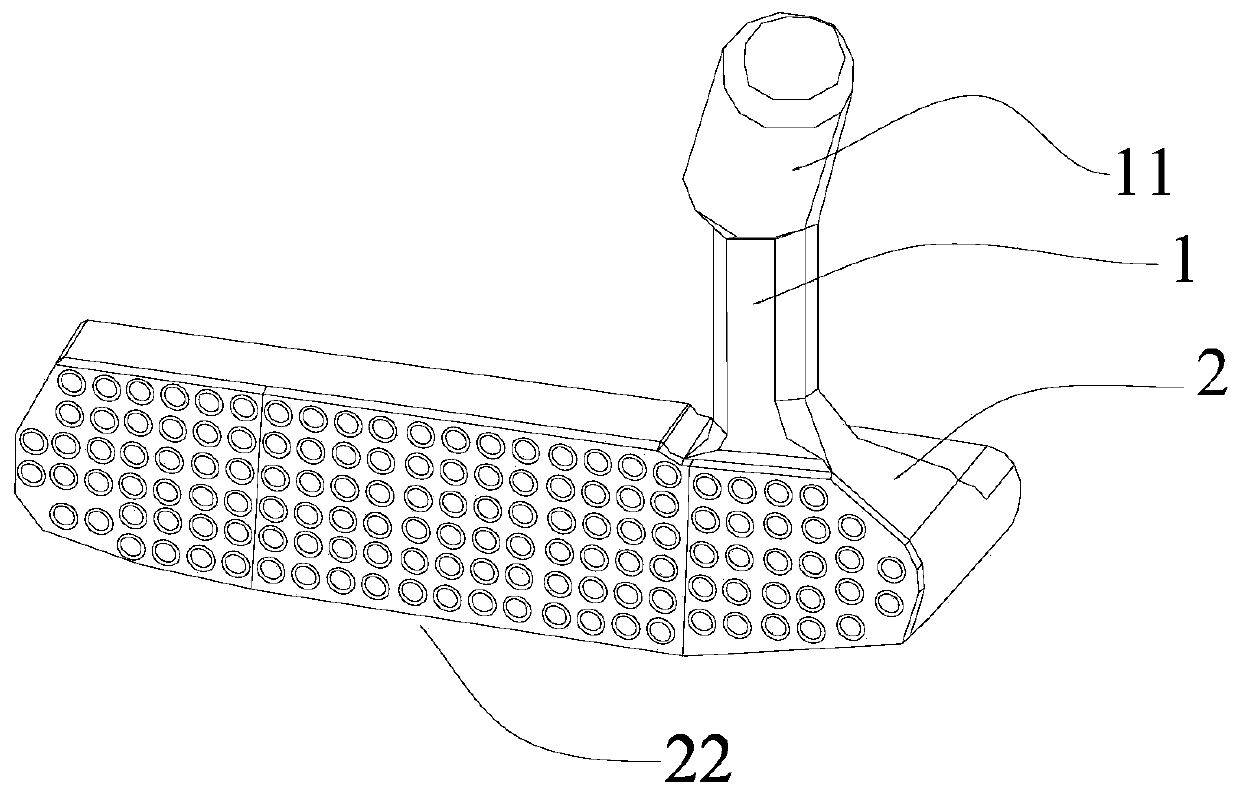

[0031] figure 2 and image 3 The distribution is an exploded view and an overall schematic view of a golf putter head according to an embodiment of the present invention. Such as figure 2 and image 3 As shown, the golf putter head includes a shaft 1 and a shaft body 2 . One end of the rod body 1 is provided with a sleeve 11 . The club head body 2 has a ball-hitting panel portion 21, and the ball-hitting panel portion 21 is respectively fixedly connected with a first panel connector 31, a second panel connector 32, a third panel connector 33, and the first panel connector. 31 is provided with a number of rectangular arrays (6 × 12) of the first striking unit 221, the second panel connector 32 is provided with a number of arrays of the second striking unit 222, and the third panel connector 33 is provided with a number of The third striking unit 223 of the array, the first striking unit 221, the second striking unit 222, and the third striking unit 223 are circular protr...

Embodiment 2

[0036] Figure 5 It is a structural schematic diagram of a golf putter head according to another embodiment of the present invention. Such as Figure 5 As shown, the golf putter head includes a shaft 1 and a shaft body 2 . One end of the rod body 1 is provided with a sleeve 11 . The club head body 2 has a ball-hitting panel part, and a mounting groove is provided in the ball-hitting panel part to embed the fourth panel connector 34, the fifth panel connector 35, and the sixth panel connector 36. The two sides of the mounting groove are toe surfaces. 211 and heel face 212, toe face 211, heel face 212, fourth striking unit 224 of several rectangular arrays (6×3) on the fourth panel connector 34, several rectangular arrays on the fifth panel connector 35 (6*3) the fifth hitting unit 225, the sixth hitting unit 226 of several rectangular arrays (6*3) on the sixth panel connector 36 jointly form the ball-facing surface 22, and the hardness of the toe surface 211 should be Harde...

Embodiment 3

[0038] Figure 6 It is a schematic diagram of the ball-facing surface of the golf putter head in another embodiment of the present invention. Such as Figure 5 As shown, the ball-facing surface 22 of the golf putter head of this embodiment is only formed by a plurality of elongated protrusions extending along the width direction (horizontal direction) of the ball-facing surface on a rectangular seventh panel connector 37. The seventh striking units 227 are formed, and these seventh striking units 227 are arranged at equal intervals along the vertical direction. The seventh panel connecting piece 37 and the seventh hitting unit 227 on it are forged and heat-treated by the following method: select a 303 stainless steel bar at a high temperature of 800-1000°C, and carry out rough forging, medium forging and fine forging in sequence. Forging, so as to obtain the seventh panel connector 37 and the seventh striking unit 227 thereon. Heat it up to 1040°C in a vacuum furnace and he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com