Oiling device for waterproof coiled material

A technology of oiling device and waterproof membrane, which is applied to the device and coating of the surface coating liquid, which can solve the problems of oil waste, damage to the health of the staff, and inconvenience, so as to avoid oil waste and improve coil Material product quality, avoiding health effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

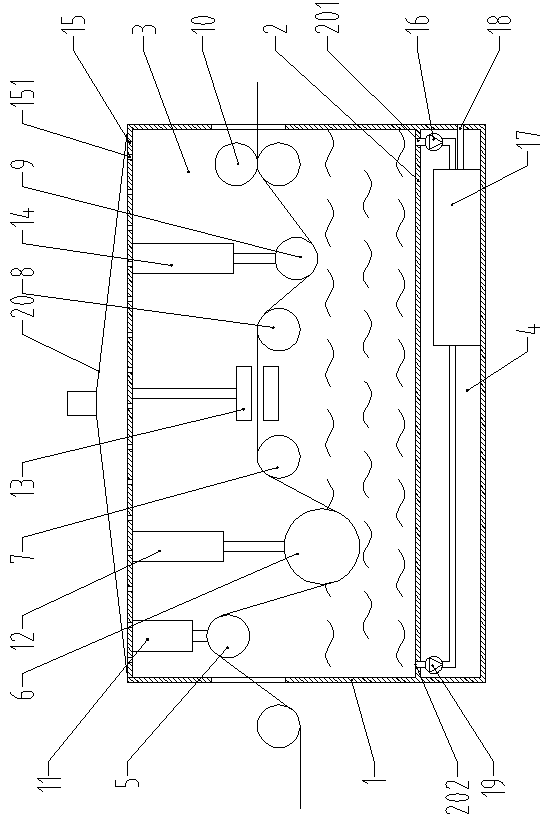

[0019] Such as figure 1 As shown, the present invention provides an oiling device for a waterproof coiled material, comprising a box body 1, a partition 2 is arranged inside the box body 1, and the partition board 2 divides the inner cavity of the box body 1 into an oiling chamber 3 and the heating chamber 4, the upper cavity of the partition 2 is the oiling chamber 3, and the lower cavity of the partition 2 is the heating chamber 4; the inside of the oiling chamber 3 is sequentially provided with a tension roller 5 and an oiling roller 6 , the first cloth roller 7, the second cloth roller 8, the auxiliary oiling roller 9 and the thickness-fixed pressure roller 10; the tension roller 5 is connected with the first telescopic device 11, and the tension roller 5 can Under the action of the expansion device 11, the rise or fall is realized, and then the tension of the oiled coil is adjusted; the oil application roller 6 is connected with the second expansion device 12, and the oil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com