Method for field welding construction inspection and remote monitoring

A technology of remote monitoring and on-site welding, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of unfavorable popularization and use, and failure to realize real-time monitoring and management of on-site construction quality, so as to ensure construction quality, The effect of reducing qualification requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

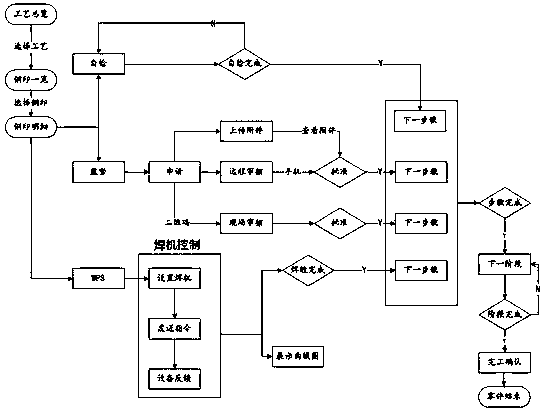

[0048] by attaching figure 1 It can be seen that the present invention relates to a method for on-site welding construction inspection and remote monitoring. Monitor each step of the on-site welding construction; wherein, the self-inspection is set to be self-inspection after each step of the on-site construction is completed, and the self-inspection can only enter the next process after passing the self-inspection; the remote The audit control procedure includes on-site construction personnel proposing supervision and audit, and remote audit personnel actively monitor and audit through the system.

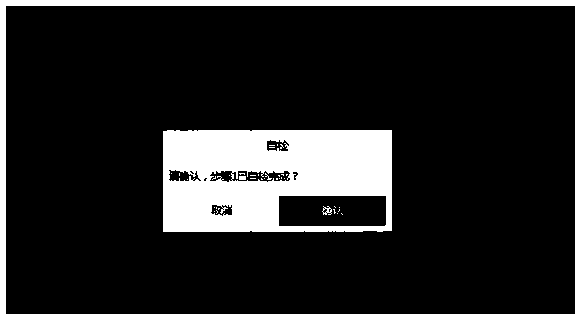

[0049] The self-inspection set in the procedure of the on-site welding construction operation instruction book is set in the on-site welding construction operation instruction program, and after each operation step is completed, the self-inspection dialogue prompt pops up on the operation interface (as attached figure 2 shown), please confirm that the self-test has been complete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com