Construction track slippage monitoring method

A building and sliding technology, which is applied in the field of monitoring and building monitoring, can solve the problems of difficult monitoring of building track slipping, achieve the effect of convenient control and data processing, and ensure safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

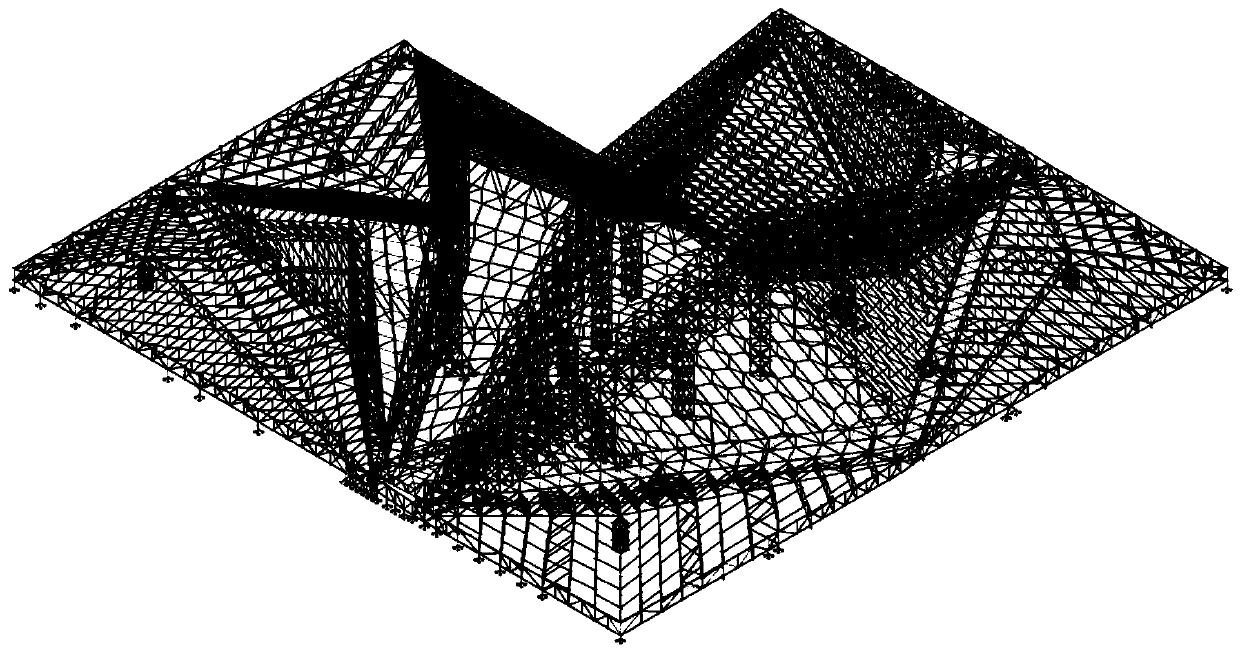

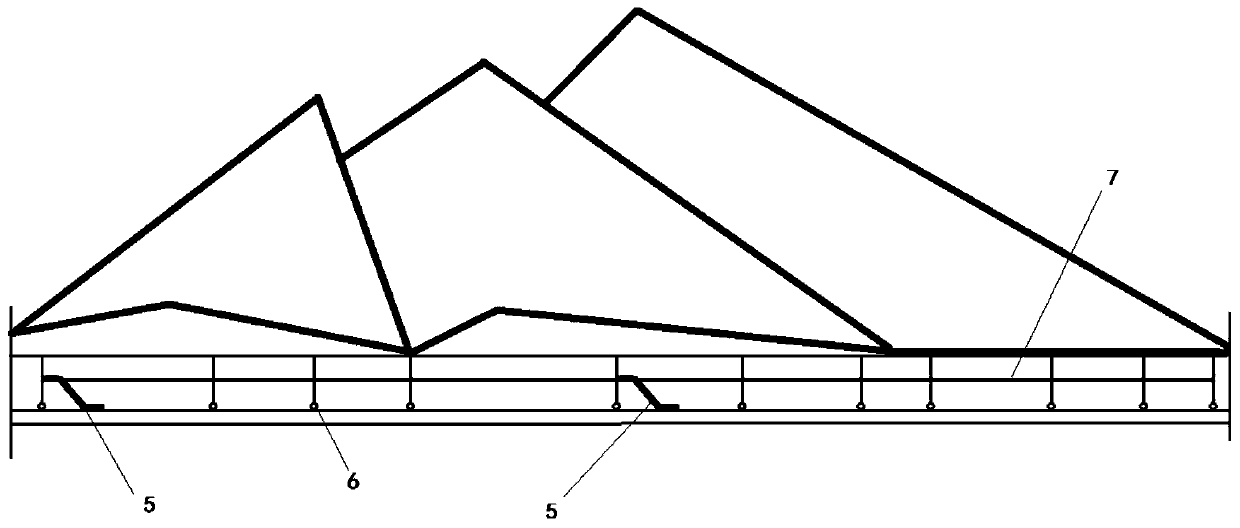

[0038] Attached below Figure 1-4 The specific implementation manner of the present invention will be described in further detail.

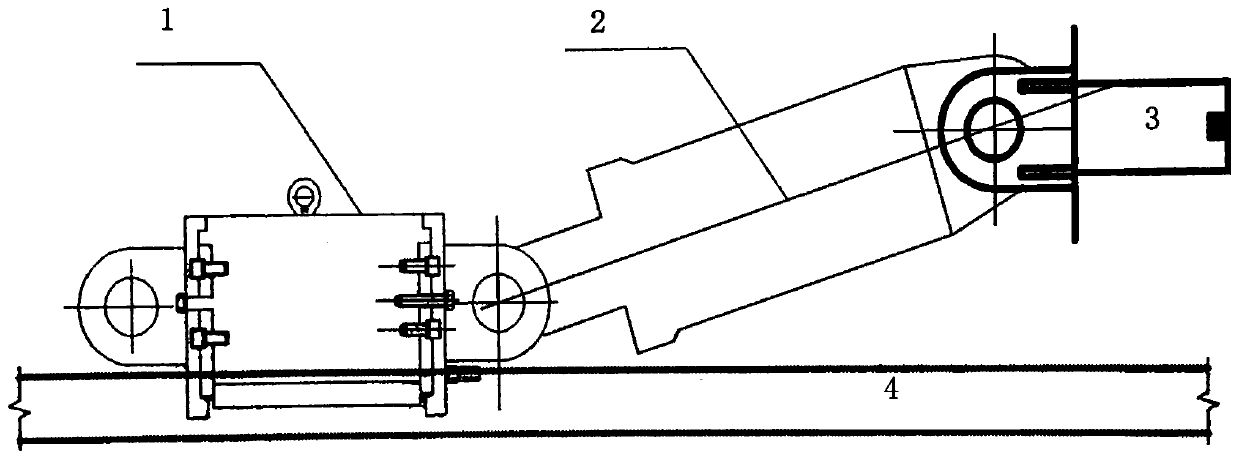

[0039] like figure 1 As shown, the present embodiment takes a building in a certain place as an example. The building 3 is a large-span steel structure, and 14 pushers 5 are used in the sliding construction, and 6 are respectively arranged in the front and middle sections of the structural sliding plane. , each sliding track 4 is 2, and the pusher 5 of the middle section is arranged on the column foot of the larger track support frame of the vertical force. When sliding as a whole, in order to ensure the minimum relative displacement on each track 4, the support 6 of each track 4 is respectively connected with a flexible connecting rod 7, taking one of the tracks as an example, the connecting rod 7 and the pusher Arranged as figure 2 shown. like image 3 As shown, the ejector 5 is structured as image 3 As shown, it includes a clamping sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com