A method for detecting die-cutting pressure with a die-cutting machine pressure testing device

A die-cutting pressure and pressure testing technology, applied in the direction of measuring devices, force/torque/work measuring instruments, instruments, etc., can solve the problem of staying in theory, experiment and simulation, accurate measurement of die-cutting pressure less involved, die-cutting pressure reference Poor performance and other problems, to achieve the effect of reducing errors, reducing bias errors, and improving the precision of die-cutting pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

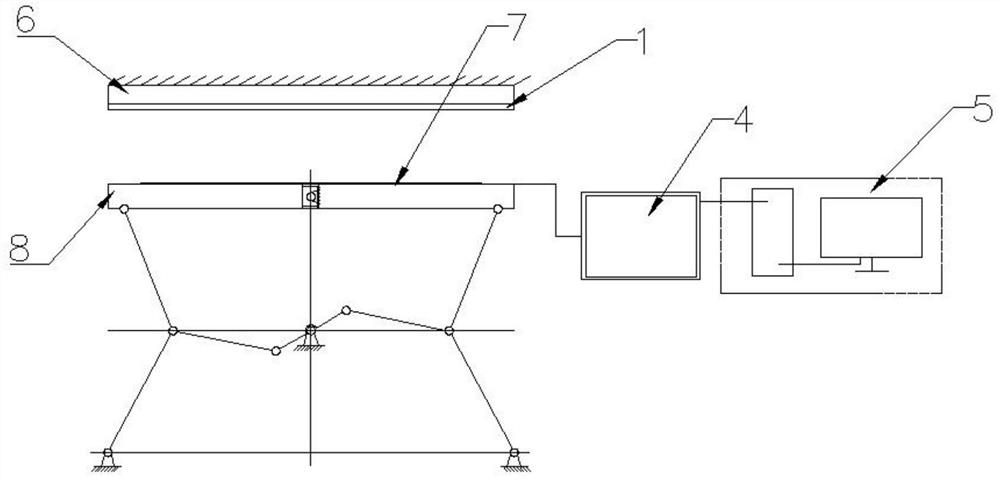

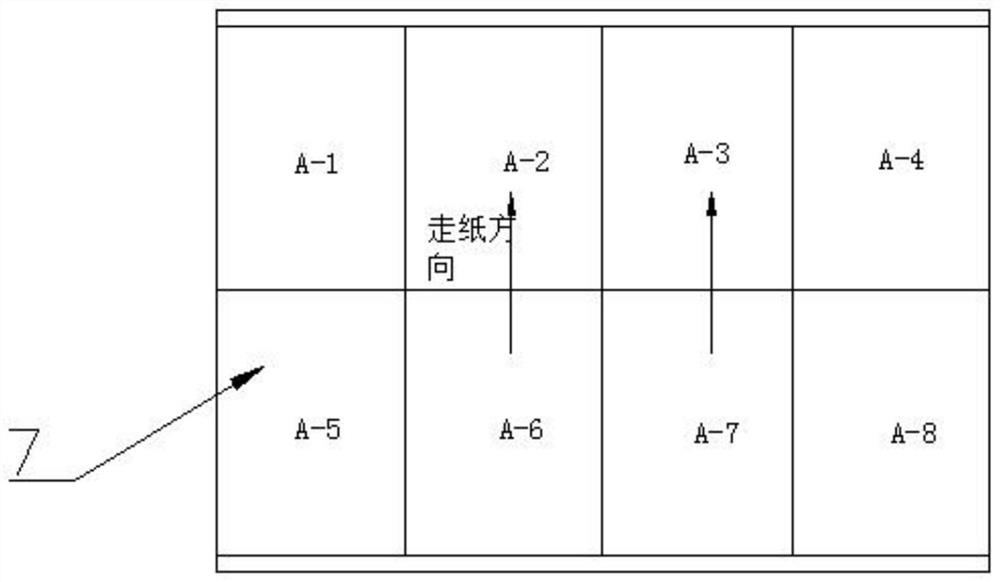

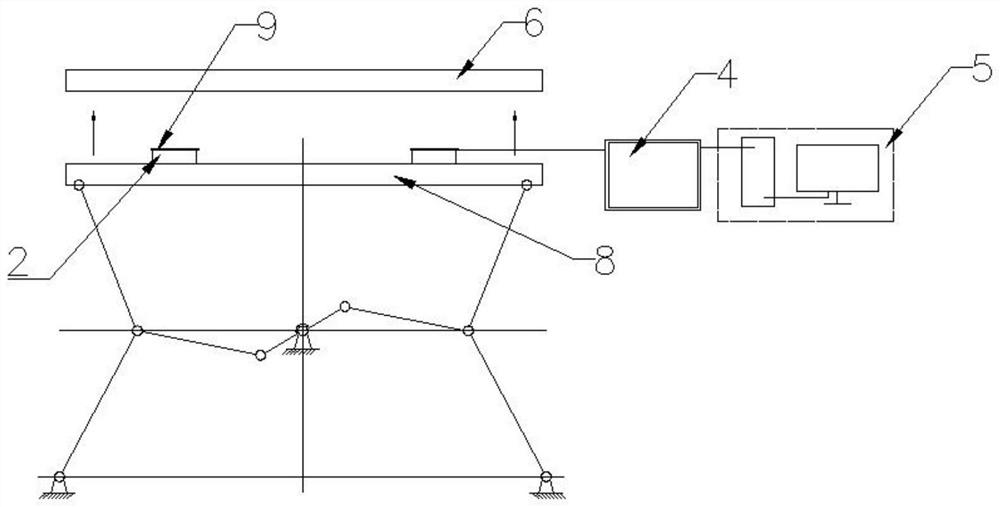

[0033] Combine Figure 1 to Figure 5 Shown is a method for detecting die-cutting pressure with a die-cutting machine pressure testing device. In this embodiment, the die-cutting machine pressure testing device includes die-cutting rubber plate tooling 1, standard pad 2, pressure sensitive paper, A die-cutting pressure resolution system 4 and a computer data processing system 5 equipped with a data processing unit. The die-cutting pressure resolution system 4 includes a scanning module and an analysis and calculation module. The pressure paper is scanned to calculate the color range and depth of the die cutting pressure on the pressure sensitive paper. The analysis and calculation module is used to analyze the color range and depth on the pressure sensitive paper to obtain the initial data of the die cutting pressure and the mold Shear pressure distribution graph,

[0034] The method of detecting die cutting pressure includes the following steps:

[0035] S1. Fix the die-cutting r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com