Object arrangement method and device and storage medium

A technology of objects and sorting boxes, applied in the field of data processing, can solve problems such as waste of sorting space, achieve the effect of improving space utilization and solving waste of sorting space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

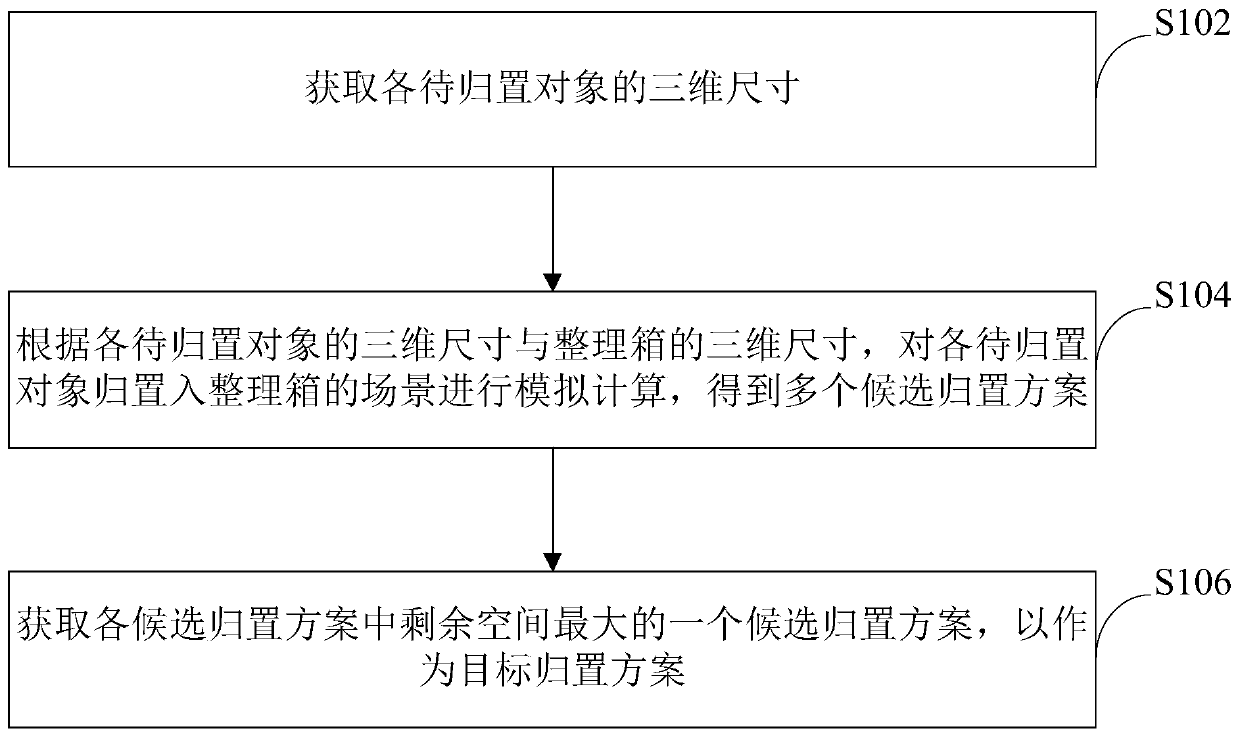

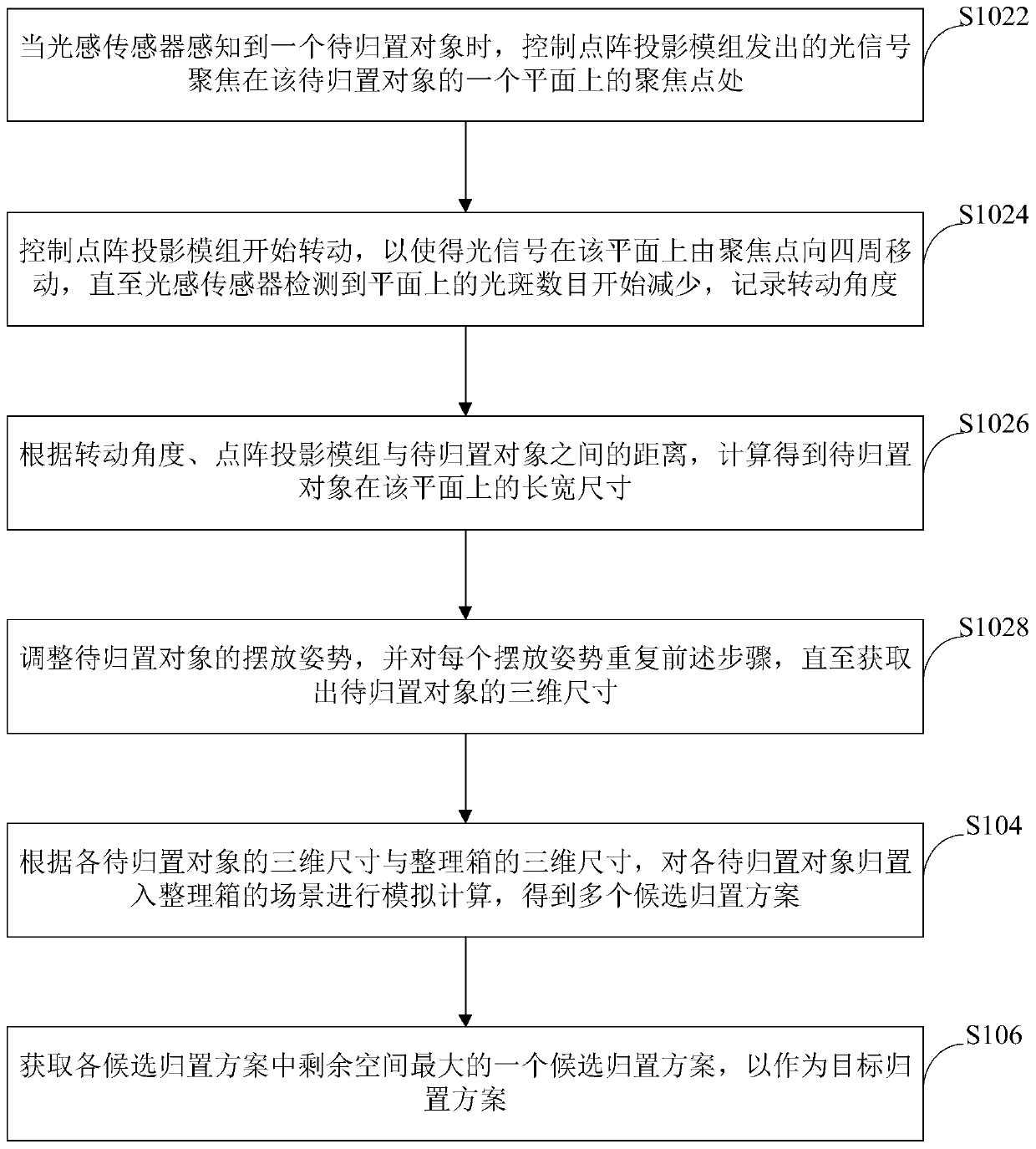

[0040] An embodiment of the present invention provides a method for organizing objects. Please refer to figure 1 , the method includes the following steps:

[0041] S102. Acquire the three-dimensional size of each object to be placed.

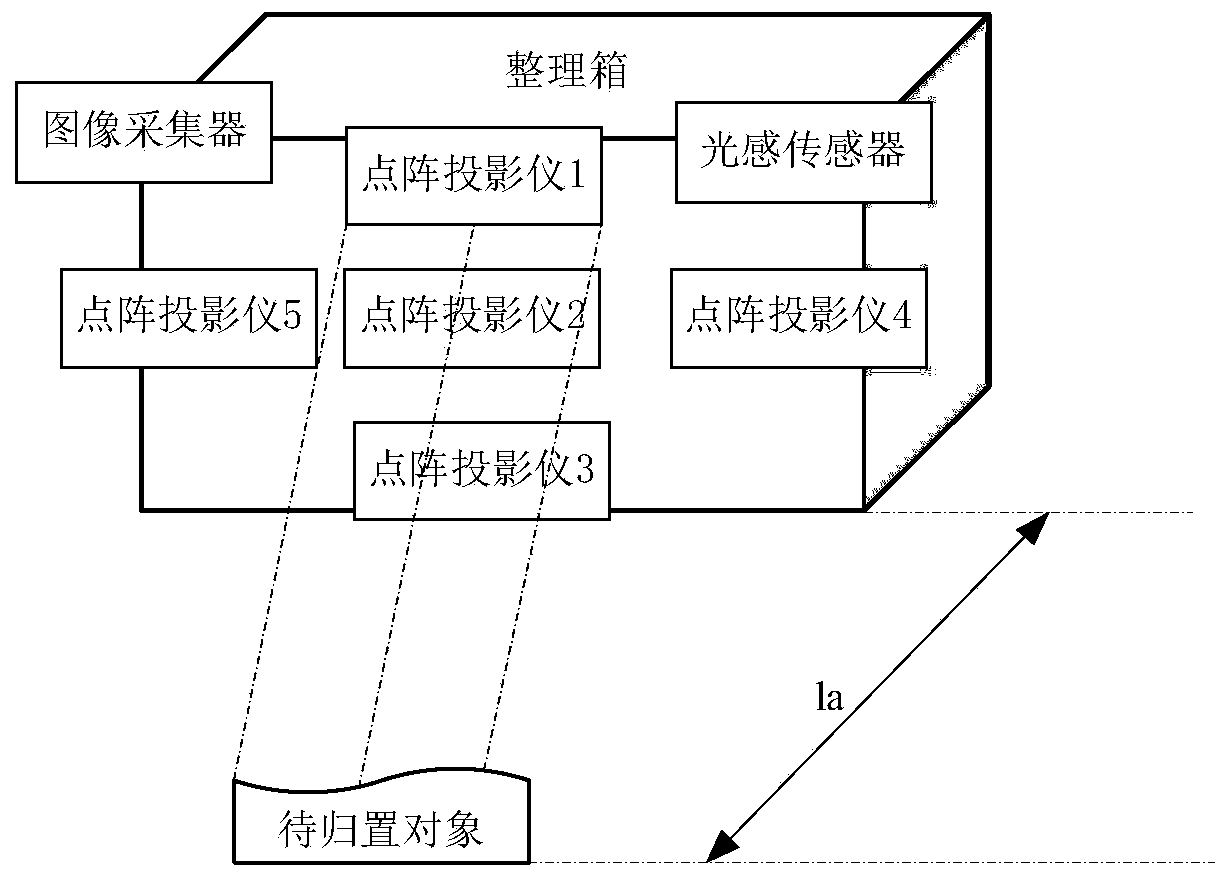

[0042] Hereinafter, for the convenience of description, the three-dimensional dimensions involved in the embodiment of the present invention are defined as: x*y*z. That is, the three-dimensional size is characterized by the numerical values on the x-axis, y-axis and z-axis in the three-dimensional space coordinate system.

[0043] Among them, taking the three-dimensional coordinate system where the sorting box is located as the benchmark, the x-axis is used to indicate the length of the sorting box in the three-dimensional coordinate system, the y-axis is used to indicate the width of the sorting box in the three-dimensional coordinate system, and the z-axis is used to indicate the width of the sorting box in the three-dimensional coordinat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com