Welding method

A welding method and technology of welding strips, which are applied in the field of solar photovoltaics, can solve the problems of inaccurate welding of welding strips and easy displacement of welding strips, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

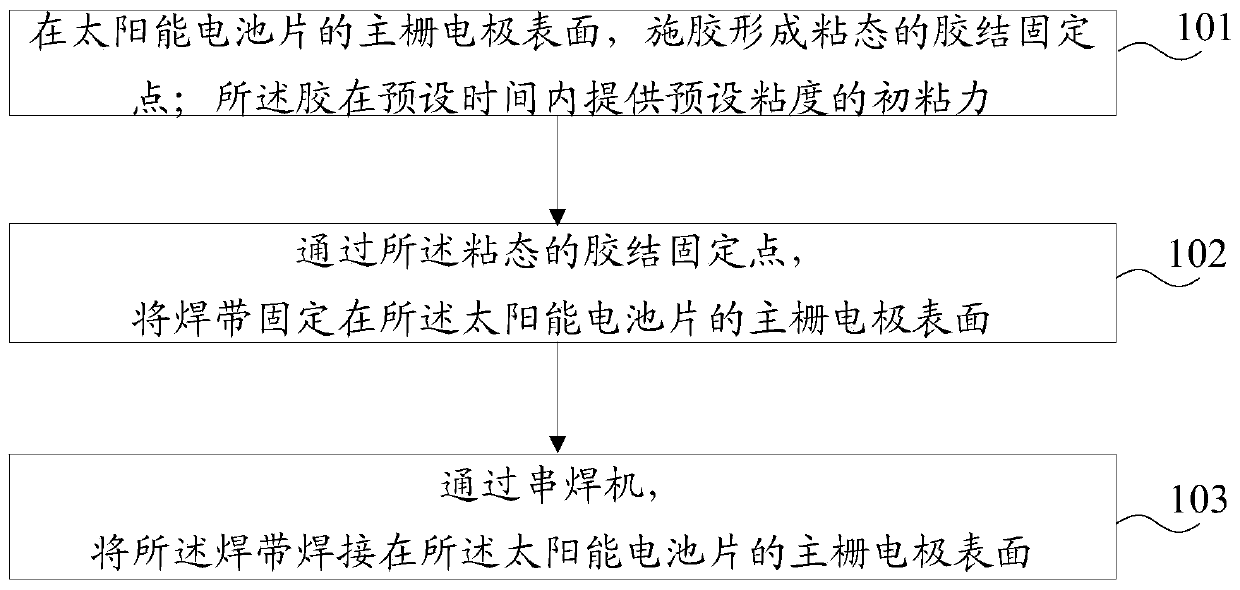

[0041] refer to figure 1 , shows a flow chart of a welding method in Embodiment 1 of the present invention, which may specifically include the following steps:

[0042] Step 101 , applying glue on the surface of the busbar electrode of the solar cell to form a viscous bonding point; the glue provides an initial adhesion force of a preset viscosity within a preset time.

[0043] In the embodiment of the present invention, the main grid of the solar cell can be multi-bus or single bus, and the multi-bus solar cell can be a solar cell with the number of main grids greater than or equal to 2. In the embodiment of the present invention, This is not specifically limited. For example, the number of busbars of the solar battery sheet may be 3, or the number of busbars of the solar battery sheet may be 6, or the number of busbars of the solar battery sheet may be 20.

[0044] In the embodiment of the present invention, glue can be applied on the surface of the main grid electrode of ...

Embodiment 2

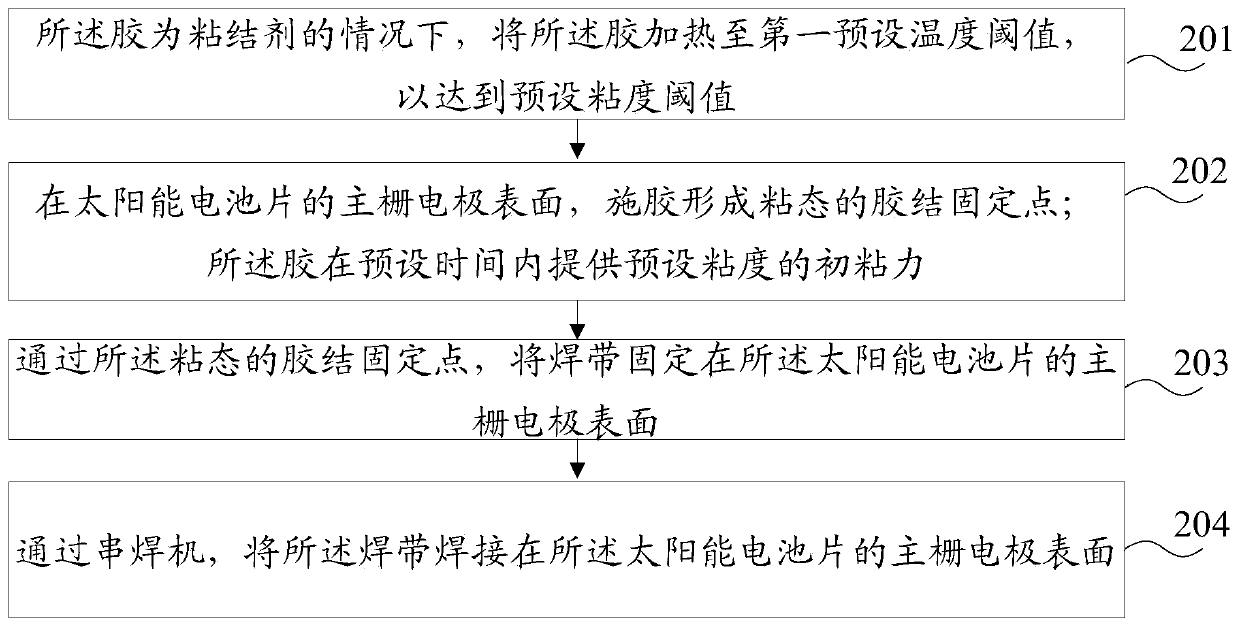

[0088] refer to figure 2 , figure 2 A flow chart of a welding method according to Embodiment 2 of the present invention is shown, which may specifically include the following steps:

[0089] Step 201, if the glue is an adhesive, heating the glue to a first preset temperature threshold to reach a preset viscosity threshold.

[0090] In the embodiment of the present invention, if the glue is an adhesive, the glue or adhesive may be heated to a first preset temperature threshold, so that the glue or adhesive reaches a preset viscosity threshold. Both the first preset temperature threshold and the preset viscosity threshold can be set according to actual needs, which are not specifically limited in this embodiment of the present invention.

[0091] For example, the first preset temperature threshold may be 90-150° C., that is, the glue or adhesive may be heated to 90-150° C., so that the viscosity of the glue or adhesive reaches the preset temperature threshold, for example. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com