Manufacturing process used for producing PCB boards by using horizontal tin deposition

A technology of PCB board and manufacturing process, which is applied in the field of manufacturing process of PCB board using horizontal immersion tin, which can solve the problems that are not easy to fade and affect the quality of PCB board, so as to reduce ionic pollutants, improve the quality of PCB board production, and step by step Clear and Easy Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

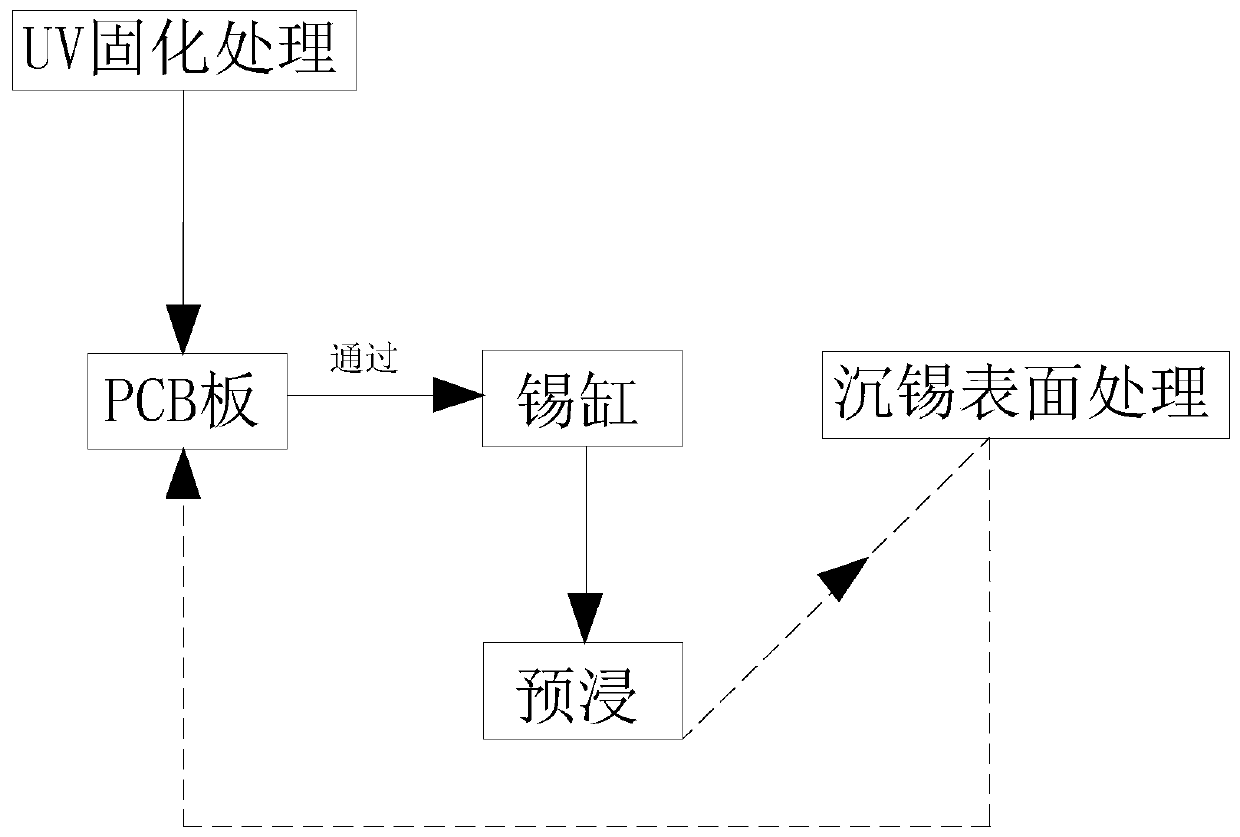

[0024] refer to figure 1 , the embodiment of the present invention provides a kind of manufacturing process that utilizes level immersion tin to produce PCB board, comprises, executes manufacturing process: make PCB board pass through each tin cylinder that is arranged horizontally; When executing manufacturing process, perform the following steps:

[0025] UV curing treatment on PCB board;

[0026] Perform pre-soaking treatment on each tin cylinder;

[0027] Immersion tin surface treatment on the PCB board.

[0028] In this embodiment, UV curing is ultraviolet curing, wherein UV is the English abbreviation of ultraviolet light, curing refers to the process of converting a substance from a low molecular weight to a high molecular weight, and UV curing generally refers to coatings (paints) and inks that need to be cured by ultraviolet rays. , Adhesive (glue) or other curing conditions or requirements for potting and sealing agents; use horizontally set tin tanks to sink tin, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com