Water-cooled converter liquid injection and liquid drainage device

A technology of liquid drainage device and converter, which is applied in the direction of cooling/ventilation/heating transformation, etc., which can solve the problems of single function, poor convenience, and low efficiency, so as to meet the liquid drainage function, improve the efficiency of liquid injection and the convenience of operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

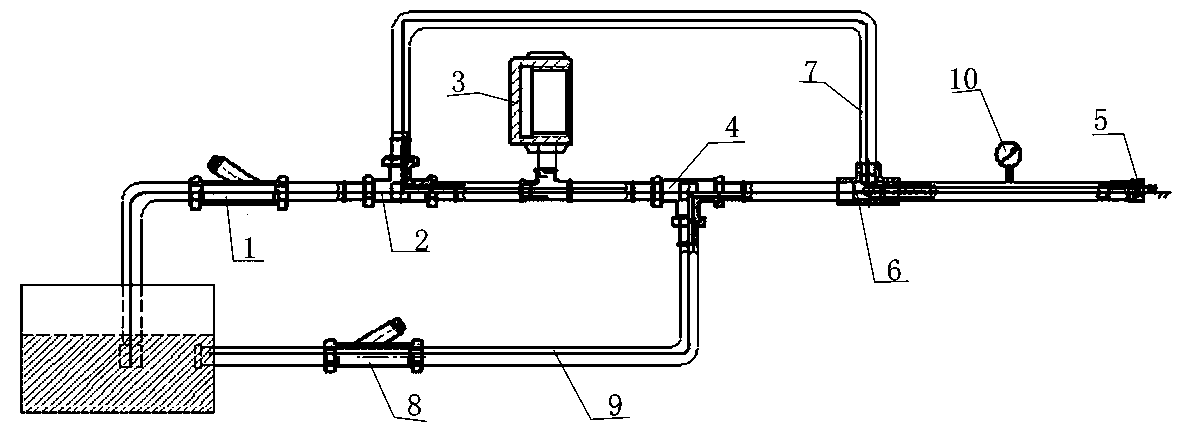

[0008] The liquid injection and discharge device of the water-cooled converter includes a liquid injection pipeline connected in sequence by the first filter 1, the first electric three-way ball valve 2, the water pump 3, the second electric three-way ball valve 4, and the quick connector 5 ; A three-way joint 6 is connected in series between the second electric three-way ball valve 4 and the quick joint 5, and the third nozzle of the three-way joint 6 (the first and second nozzles are connected to the liquid injection pipeline) and the first A discharge bypass pipe 7 is connected between the third valve port of the electric three-way ball valve 2 (the first and second valve ports are connected to the liquid injection pipeline), and the third valve port of the second electric three-way ball valve 4 is connected to it A drain main pipe 9 with a second filter 8 connected in series. During specific implementation, a pressure gauge 10 is connected in series on the injection pipeli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com