Ice blockage preventing automatic liquid injection throttling valve with liquid storage device

A technology of throttle valve and accumulator, which is applied to multi-port valves, valve devices, mechanical equipment and other directions, can solve problems such as blockage of pipelines, and achieve the effect of preventing the formation of hydrate, with simple structure and good preventive effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

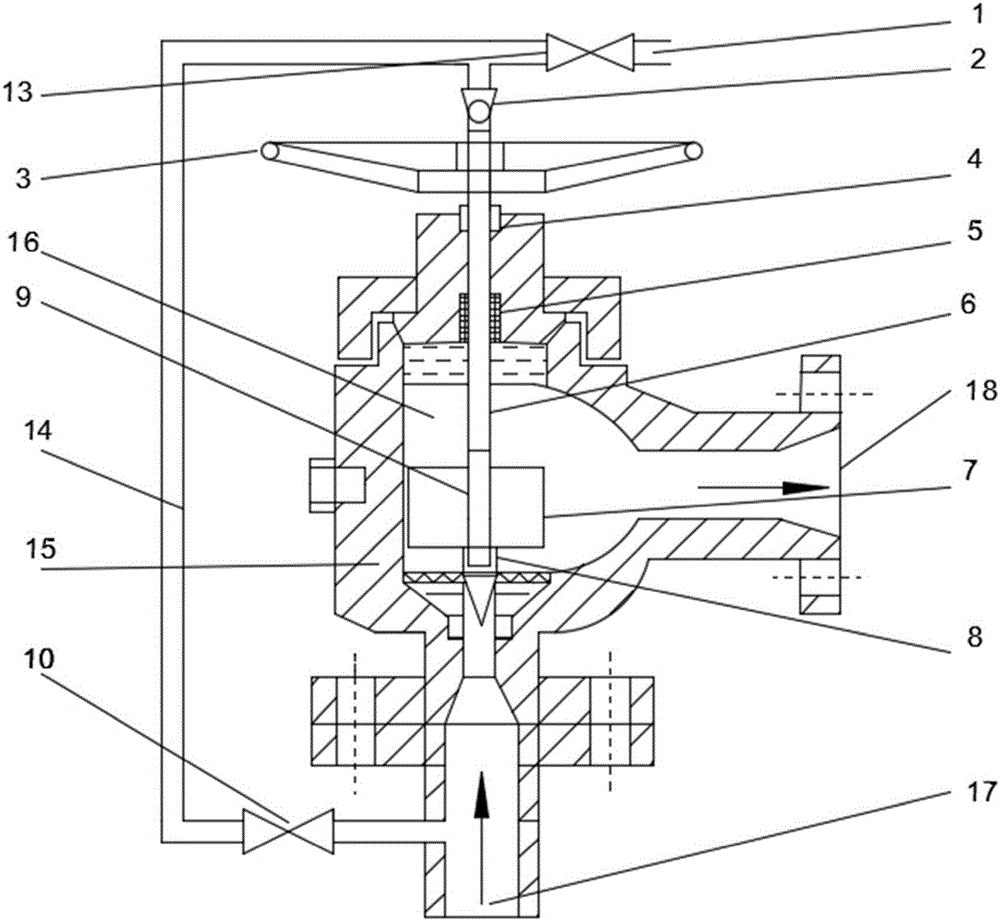

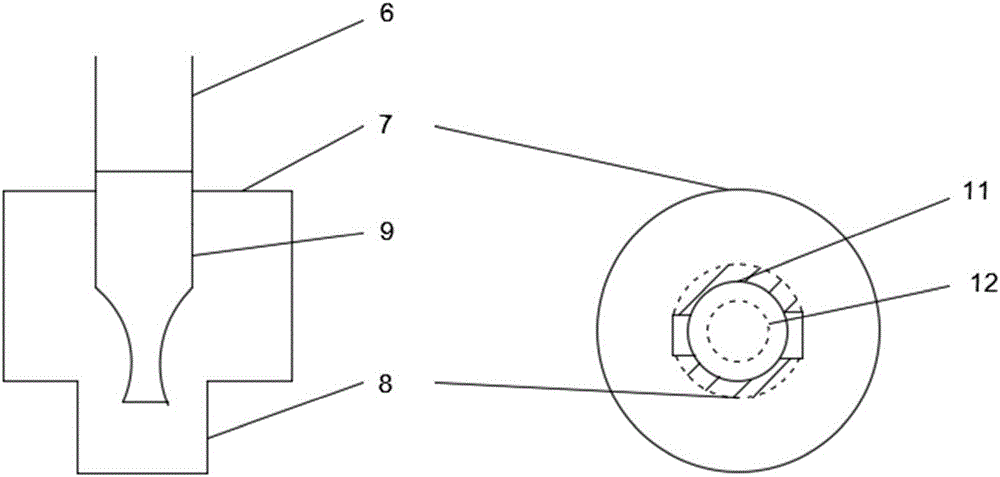

[0022] Such as figure 2 As shown, the throttle valve is mainly composed of liquid injection port 1, ball joint 2, handwheel 3, valve stem nut 4, packing seal 5, valve stem 6, liquid storage tank 7, valve disc 8, Laval nozzle 9, gate valve 10. Gate valve 13, high-pressure hose 14, and valve body 15; this throttle valve is designed in the way of low entry and high exit, and its specific implementation plan is as follows:

[0023] (1) Inject the composite hydrate inhibitor into the liquid storage tank 7. The operation steps are to first close the gate valve 10 on the high-pressure hose 14 drawn from the throttle valve inlet 17, and then open the gate valve 13 at the liquid injection port, Inject liquid into the liquid storage tank 7, and close the gate valve 13 of the liquid injection port after the liquid injection finishes.

[0024] (2) When it is necessary to adjust the throttle valve, open the gate valve 10 on the high-pressure hose 14, and then adjust the opening of the th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com