Full-automatic PRP separator general assembly

A separator and fully automatic technology, applied in the field of separators, can solve problems such as inability to achieve standardization of operations, achieve standardization of operations, standardization of processes, and avoid human operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

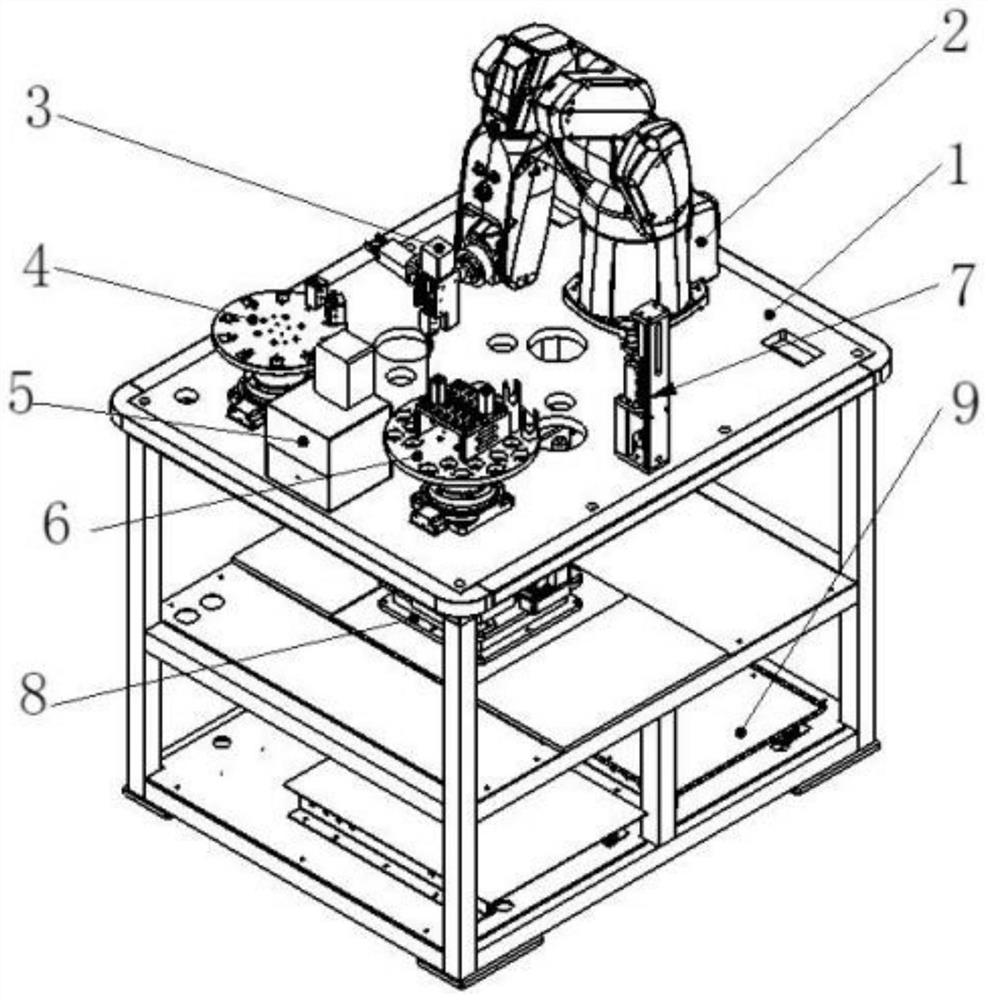

[0046] see figure 1 , 2 , 3, 4, a fully automatic PRP separator assembly, including

[0047] The support assembly constitutes the main frame structure of the separator assembly, and it is composed of a frame and a large plate 1 formed by welding the frame body and a horizontally arranged bottom plate, and the bottom bottom plate of the frame and the large plate 1 A control cabinet placement frame 9 is placed;

[0048] A separation robot, which is arranged on the upper bottom plate of the frame and the large plate 1, and is composed of a six-axis robot 2 whose bottom end is fixedly connected to the upper surface of the upper bottom plate by bolts, and the movable end of the six-axis robot 2 A separation head 3 is installed.

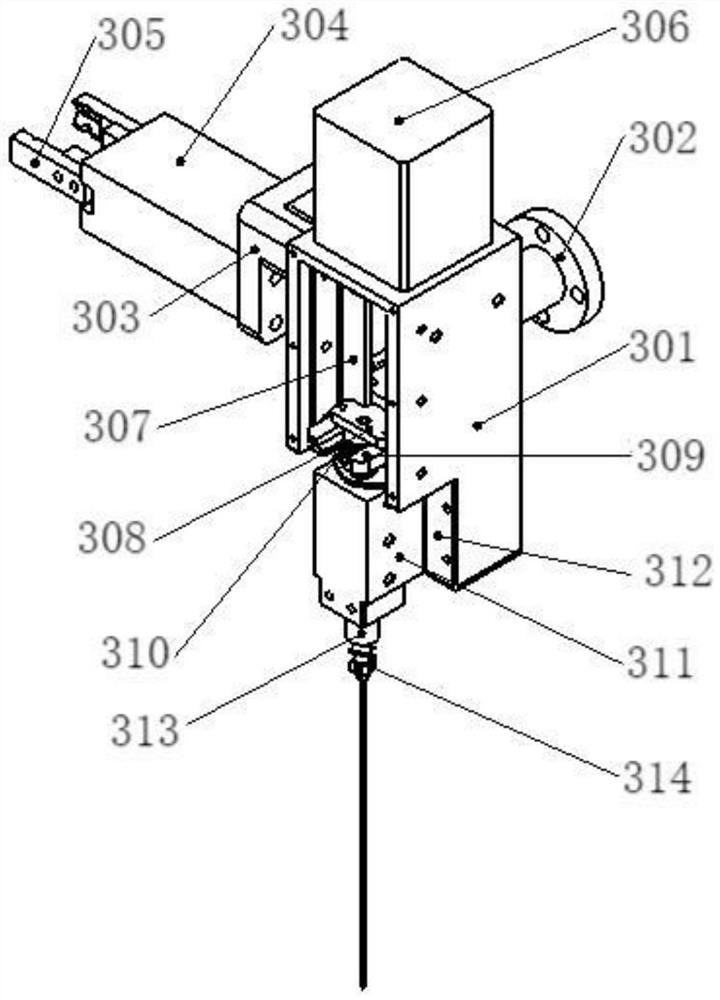

[0049] In the embodiment of the present invention, the separation head 3 is fixed on the head of the six-axis robot 2 by the connecting block 302 through screws and pins, and the separation head 3 is composed of a mounting base 301, a screw motor 306 an...

Embodiment 2

[0051] see figure 1 , 2 , 5, 6, 7, 8, 9, 10, 11, 12, 13, 14, a fully automatic PRP separator assembly, including

[0052] The support assembly constitutes the main frame structure of the separator assembly, and it is composed of a frame and a large plate 1 formed by welding the frame body and a horizontally arranged bottom plate, and the bottom bottom plate of the frame and the large plate 1 A control cabinet placement frame 9 is placed;

[0053] The syringe placement frame 4 is used to place the syringe to position the syringe, and enables the six-axis robot 2 to easily use the syringe, and it is installed on the frame and the upper bottom plate of the large board 1;

[0054] Needle sterile cap and centrifuge tube placement frame 6, which is used to place sterile caps, needles and centrifuge tubes together, and it is installed on the upper end plate of the frame and the large plate 1, and is located on the side of the syringe placement frame 4 side;

[0055] Weighing and ...

Embodiment 3

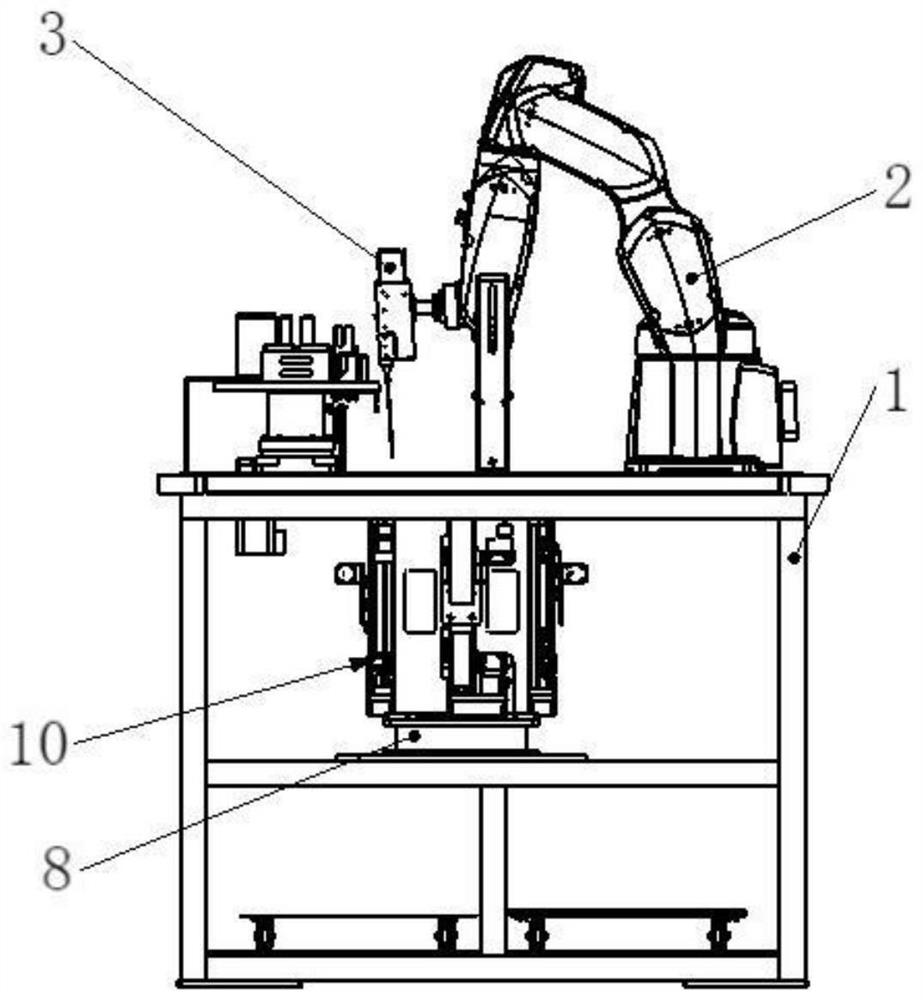

[0063] see figure 1 , 2 , 15, 16, 17, a fully automatic PRP separator assembly, including

[0064] The support assembly constitutes the main frame structure of the separator assembly, and it is composed of a frame and a large plate 1 formed by welding the frame body and a horizontally arranged bottom plate, and the bottom bottom plate of the frame and the large plate 1 A control cabinet placement frame 9 is placed;

[0065] Separation assembly, which is used to centrifugally separate the liquid in the centrifuge tube, and is arranged on the middle bottom plate of the frame and the large plate 1, and is fixed on the middle bottom plate of the frame and the large plate 1 by bolts The centrifugal drive device 8 on the plate surface and the multi-station liquid level detection mechanism 10 installed on the upper end of the centrifugal drive device 8 and sheathed on the outside of the centrifugal drive device 8 constitute.

[0066] In the embodiment of the present invention, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com