A curing furnace for curing hydrophilic aluminum foil

A technology of hydrophilic aluminum foil and curing furnace, which is applied to the surface coating liquid device, pretreatment surface, coating, etc., can solve the problem of insufficient uniformity of curing, reduce the temperature difference between the left and right PMT boards, uniform curing, and improve Effect of cure uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

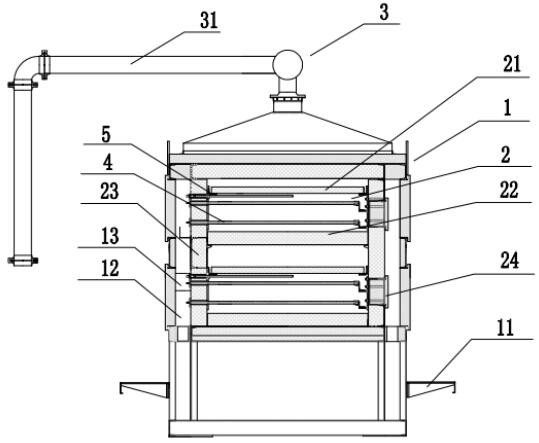

[0039] A curing oven for curing of hydrophilic aluminum foil, such as figure 1 As shown, it includes a furnace body 1, two curing passages 2 arranged up and down inside the furnace body 1, and an exhaust system 3 for treating exhaust gas in the curing passage 2.

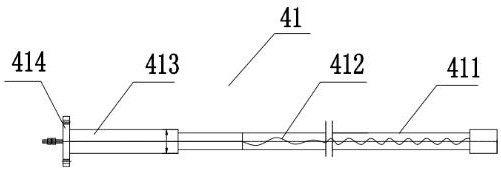

[0040] The curing channel 2 is composed of oven brackets 23 on both sides, an upper insulation layer 21 and a lower insulation layer 22; the oven bracket 23 is provided with insulation materials. The upper and lower parts of the curing channel 2 are equipped with infrared medium-wave heating tubes 4 for heating and curing the hydrophilic aluminum foil; the infrared medium-wave heating tubes 4 are perpendicular to the direction of movement of the hydrophilic aluminum foil; The temperature sensor 5 used to detect the temperature in the curing tunnel 2 is a temperature measuring thermocouple, and the temperature measuring thermocouple is provided with a thermocouple mounting sleeve. When the curing furnace works, the h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com