Turning-over clamp

A technology of overturning fixtures and rotating rods, applied in the directions of clamping, manufacturing tools, supports, etc., can solve problems such as increasing labor intensity, reducing production efficiency, and processing errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0030] In the present invention, unless otherwise specified, the used orientation words such as "upper, lower, vertical, horizontal" refer to the positional relationship in actual use.

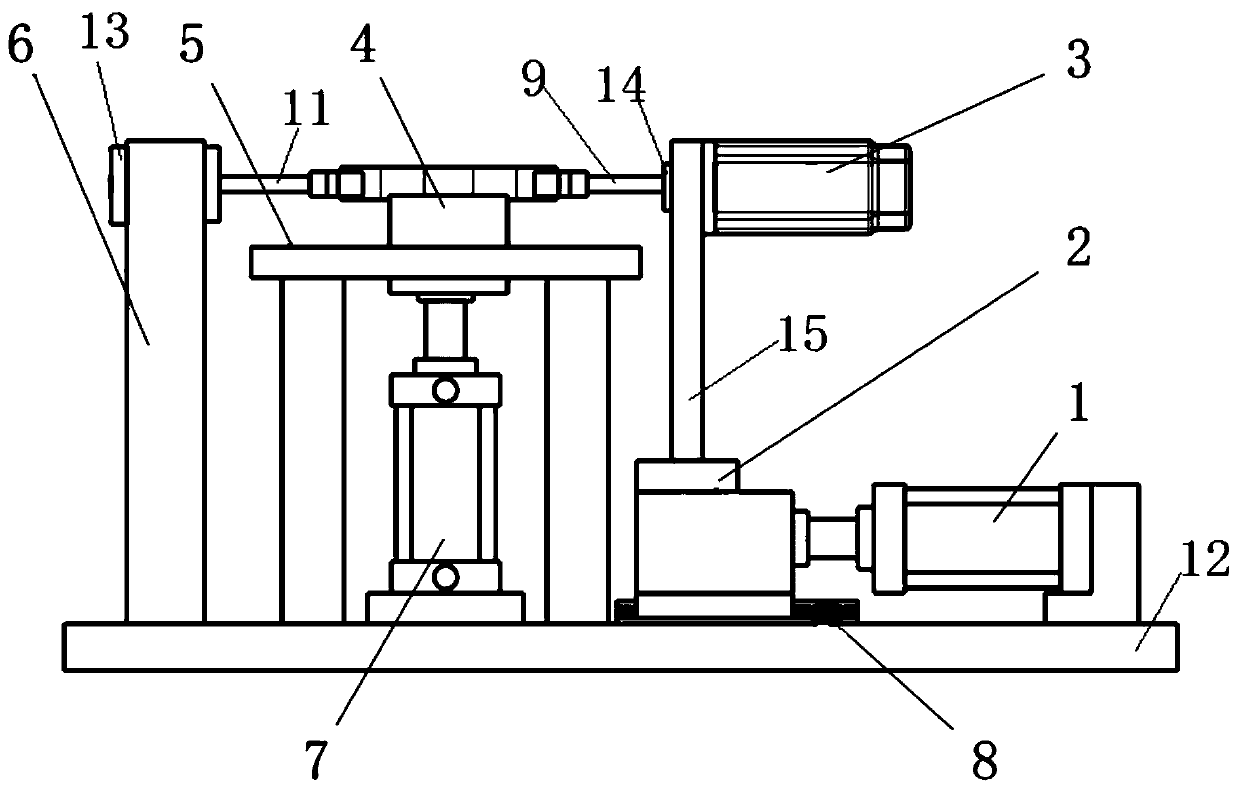

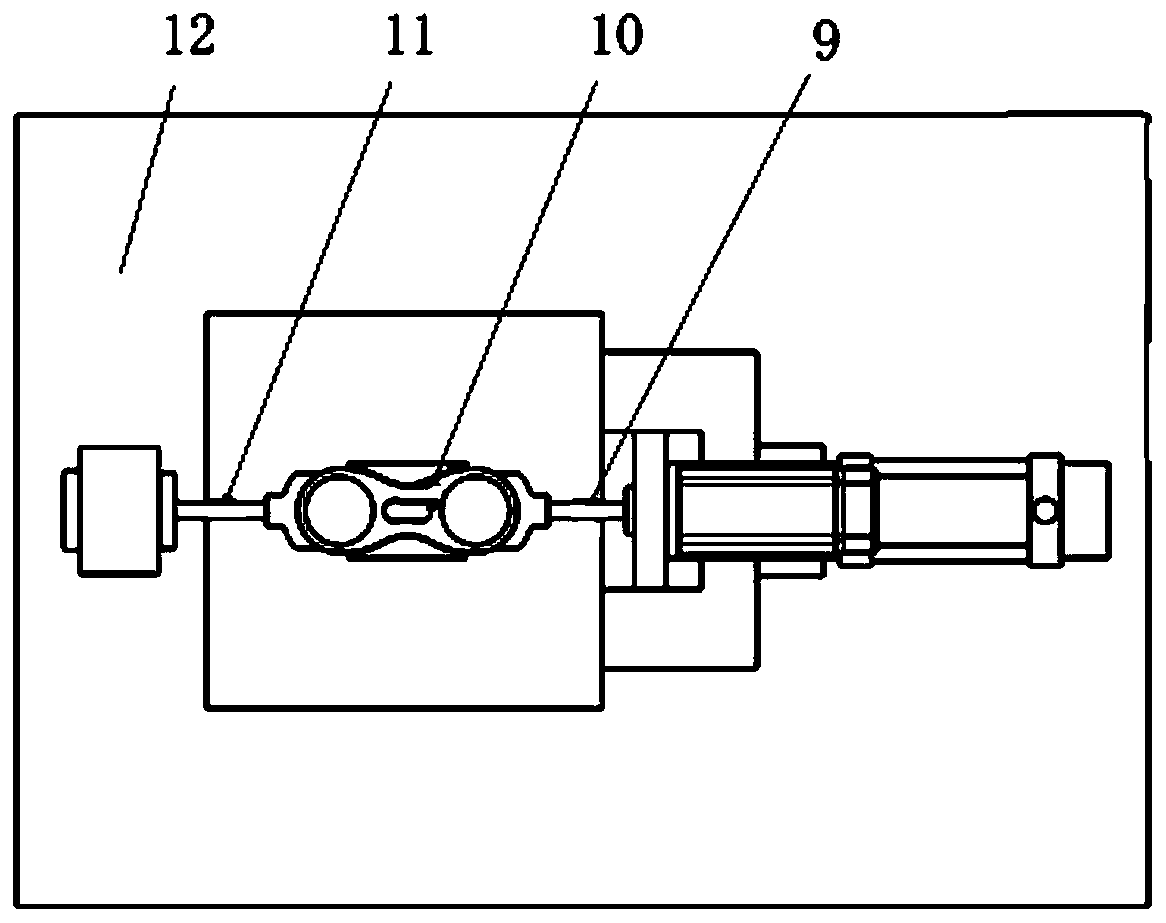

[0031] The invention provides a flipping fixture, wherein, such as figure 1 and figure 2 As shown, the flip fixture includes a first clamping unit, a workpiece placement unit, a second clamping unit and a drive unit arranged in sequence; wherein,

[0032] The first clamping unit at least includes a vertically arranged first support platform 6, a first sliding block 13 that is vertically slidably arranged on the first support platform 6, and a first sliding block 13 that is ro...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap