A paperless digital transfer inkjet printer and transfer method

A technology of digital transfer and inkjet printer, applied in printing, typewriter and other directions, can solve the problems of cumbersome process, achieve the effect of protecting the environment, reducing the use cost and expanding the scope of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

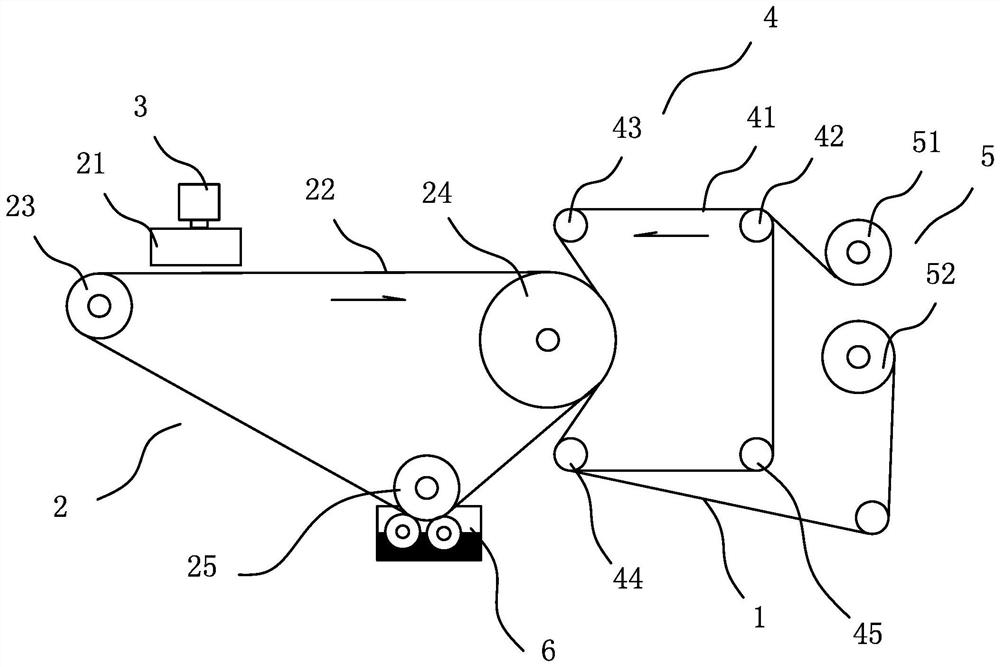

[0033] Embodiment: a kind of paperless digital transfer inkjet printer of this embodiment is used for the inkjet transfer printing on the surface of the material 1 to be printed, such as figure 1 As shown, the inkjet printer includes:

[0034] The frame is used to place the inkjet printing unit 2, the track unit 3, the transfer unit 4, the residual ink cleaning unit 6 and the feeding unit 5;

[0035] The inkjet unit, for the inkjet of pattern, comprises inkjet transfer device 21, inkjet transfer belt 22, driving roller 23, transfer roller 24, tension roller 25, and described inkjet printing apparatus will be printed pattern inkjet to inkjet transfer. On the surface of the printing belt, the inkjet transfer belt is tensioned and wound on the driving roller, transfer roller and tension roller, and the inkjet transfer belt is circulated in a continuous moving manner;

[0036] The track unit is used for the movement of the above-mentioned printing device, and the printing device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com