High-speed shaft connecting bearing for dust collector

A technology for high-speed shafts and vacuum cleaners, applied in the directions of shafts and bearings, ball bearings, bearing components, etc., can solve the problems of small installation space for vacuum cleaner bearings, increase user costs, complicated steps, etc., to avoid instability, save resources, The effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with specific drawings and embodiments.

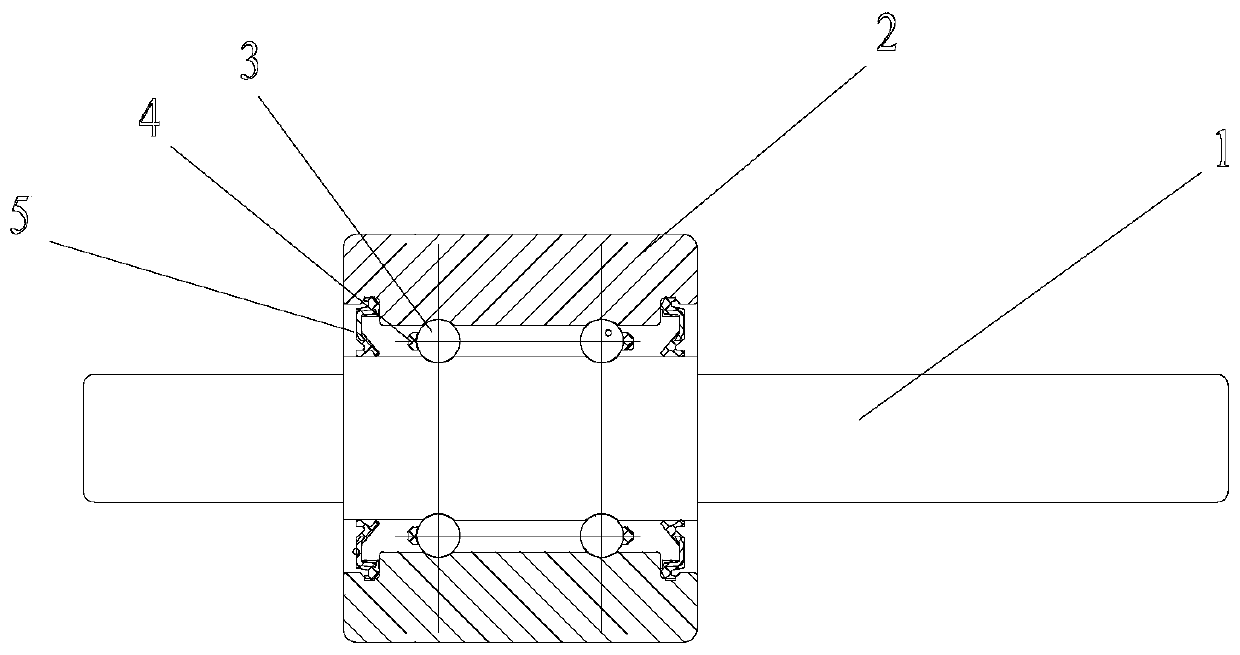

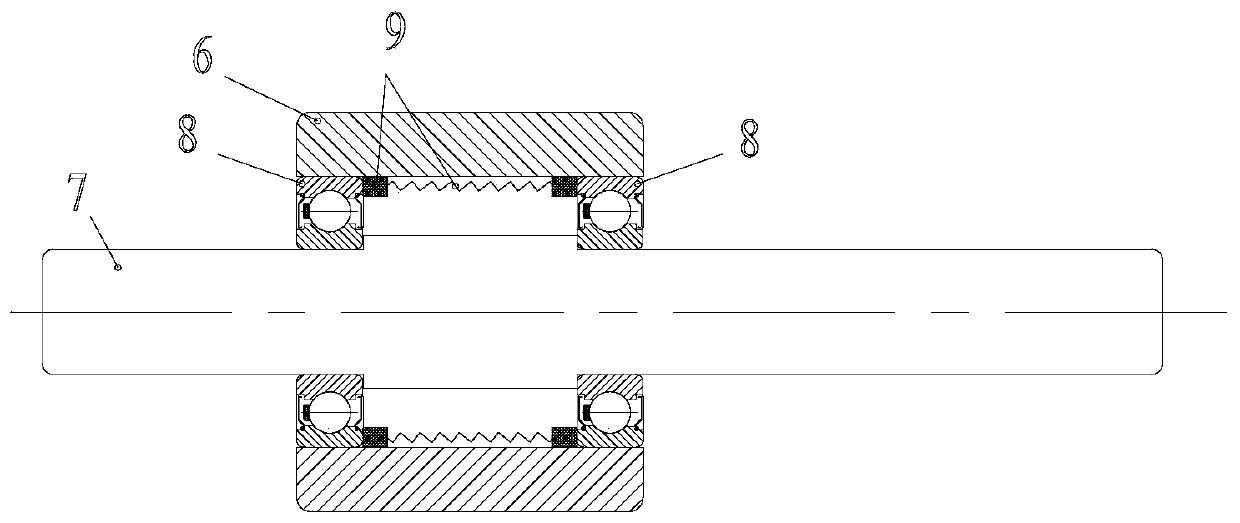

[0021] Such as figure 1 As shown, the present invention relates to a high-speed shaft-connected bearing for a vacuum cleaner, comprising a mandrel 1, an outer ring 2, rolling elements 3, a retainer 4 and a seal 5, the mandrel 1 is sleeved with an outer ring 2, and the core A cage 4 is arranged between the shaft 1 and the outer ring 2 , and several evenly distributed rolling elements 3 are arranged in the cage 4 , and seals 5 are arranged on both sides of the cage 4 .

[0022] There are two cages 4 and two rows of rolling elements 3 .

[0023] The height of the outer ring 2 is 10mm-22mm, and the height of the mandrel 1 is 35mm-60mm.

[0024] The diameter of the outer ring 2 is 10mm-26mm, and the diameter of the mandrel 1 is 3mm-12mm.

[0025] The highest operating speed of the present invention is 150,000 rev / min.

[0026] The mandrel 1 replaces the functio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com