A New Type of Fuel Oil and Gas Steam Boiler

A gas-fired steam and boiler technology, which is applied in the direction of water-tube steam boilers, steam boilers, steam generation, etc., can solve the problems of air leakage, large furnace body, and many heavy furnace walls, so as to reduce air leakage, improve safety, and overall The effect of cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] A new type of fuel-fired and gas-fired steam boiler according to the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

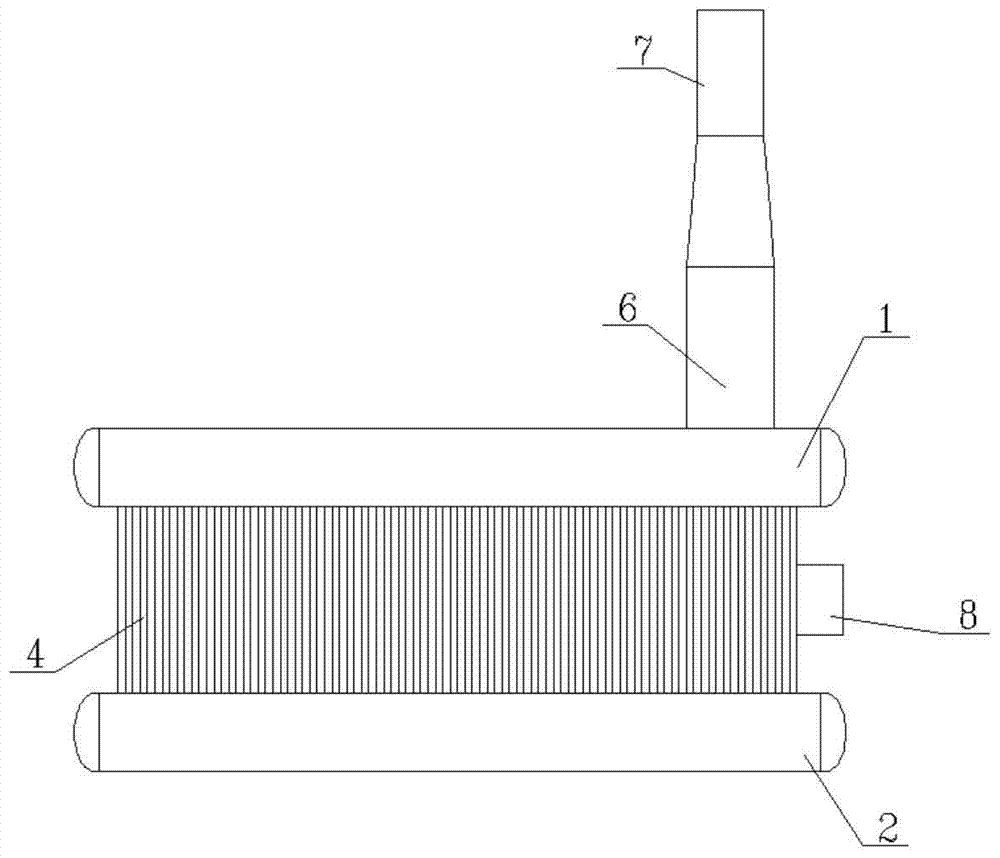

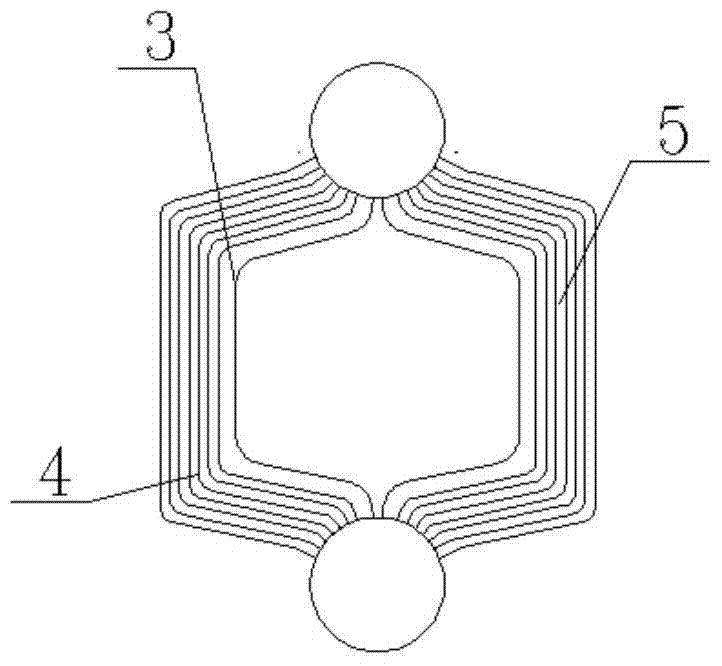

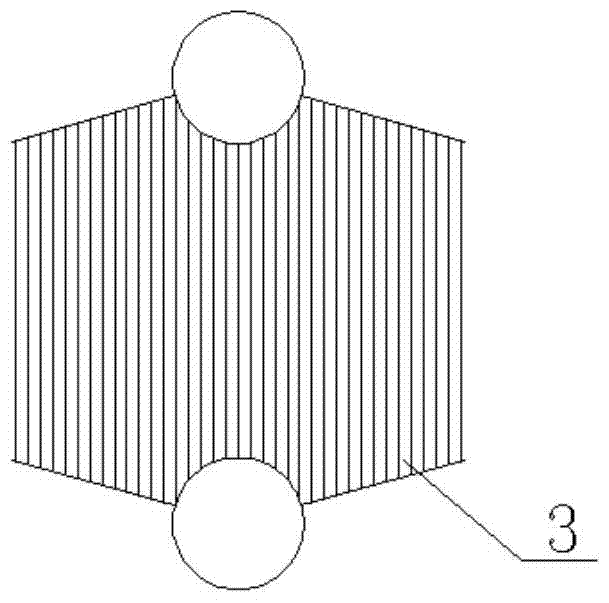

[0020] Such as Figure 1 to Figure 3 As shown, a new type of oil-fired and gas-fired steam boiler according to the present invention adopts a vertical arrangement of double drums, an O-shaped structure, and natural circulation. The boiler consists of an upper drum 1, a lower drum 2, a radiation heating surface 3, a convection heating surface 4, a superheater 5 (if necessary), an air preheater 6, a chimney 7, and a burner 8.

[0021] The connecting pipes between the upper drum 1 and the lower drum 2 constitute the radiation heating surface 3 and the convection heating surface 4, wherein the outermost connecting pipe, the innermost connecting pipe and the connection between the upper and lower drum ends The tubes are of membrane wall structure, and the innermost membrane wall const...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com