Equipment for automatic pressing fit of multi-specification crystal balls and ceramic interiors

A crystal ball and multi-specification technology, applied in special decorative structures, decorative arts, etc., can solve the problems of unsatisfactory annual production, low production efficiency, high misoperation, etc., and achieve reduced equipment procurement costs and floor space, simple structure, The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

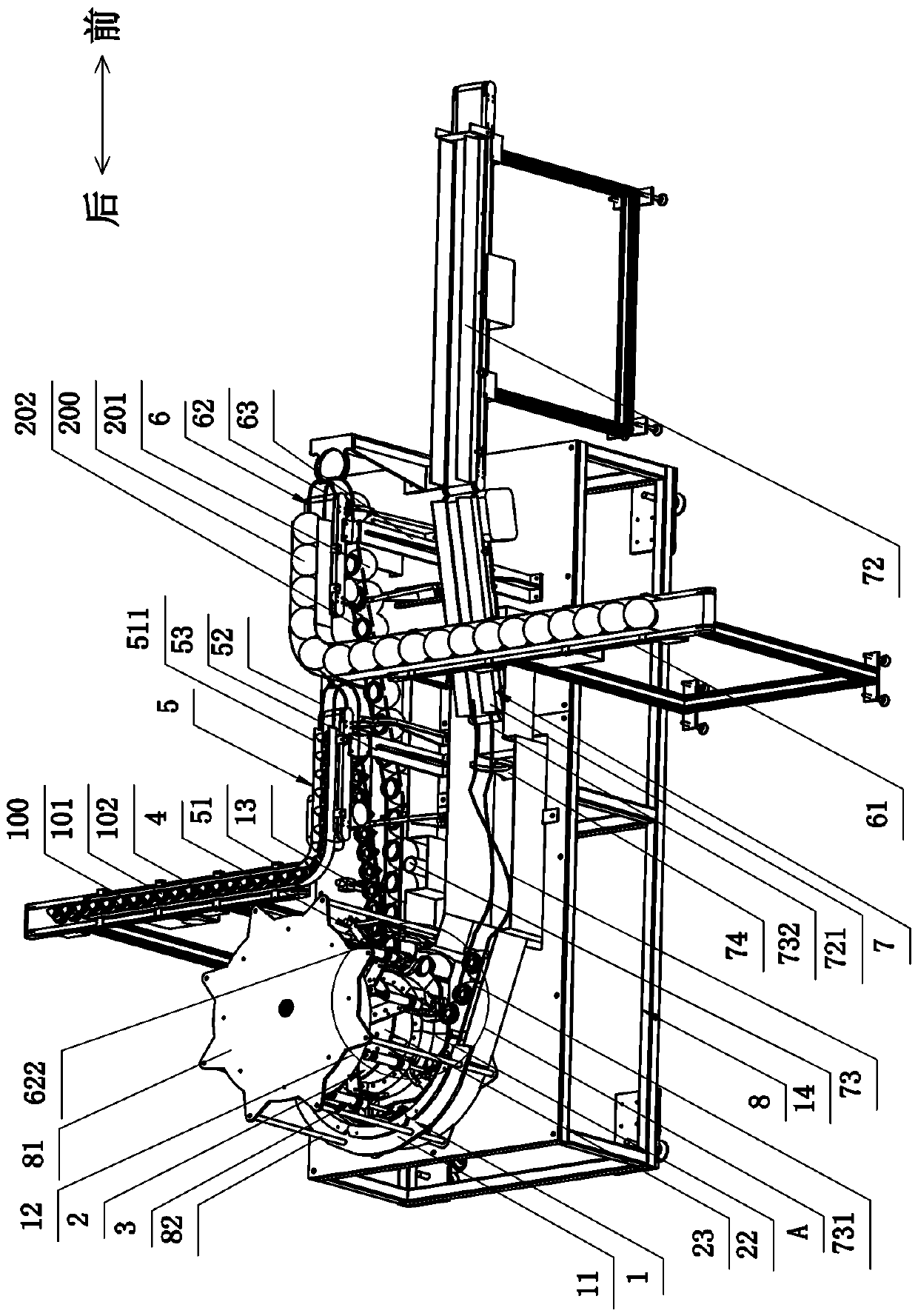

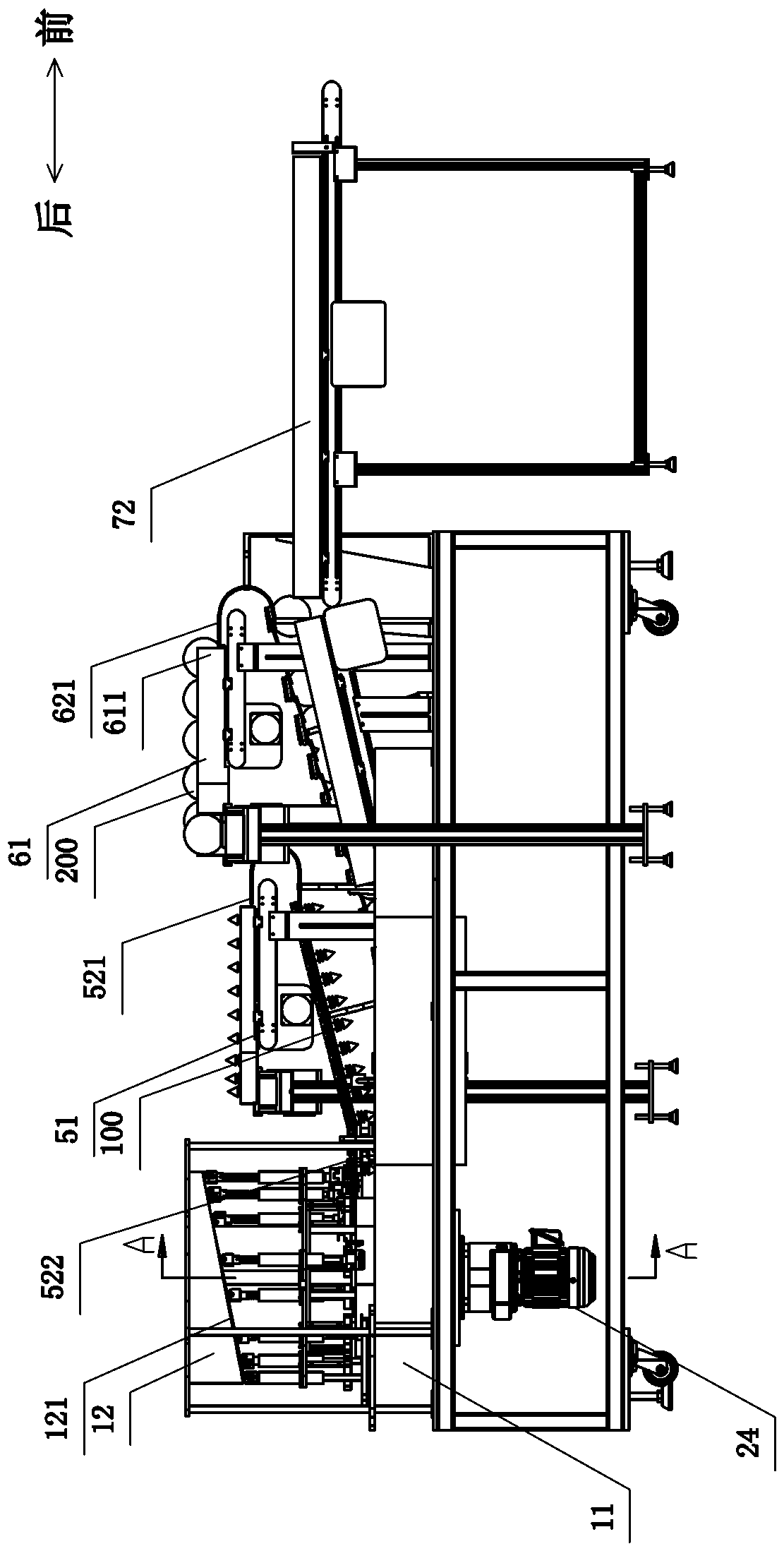

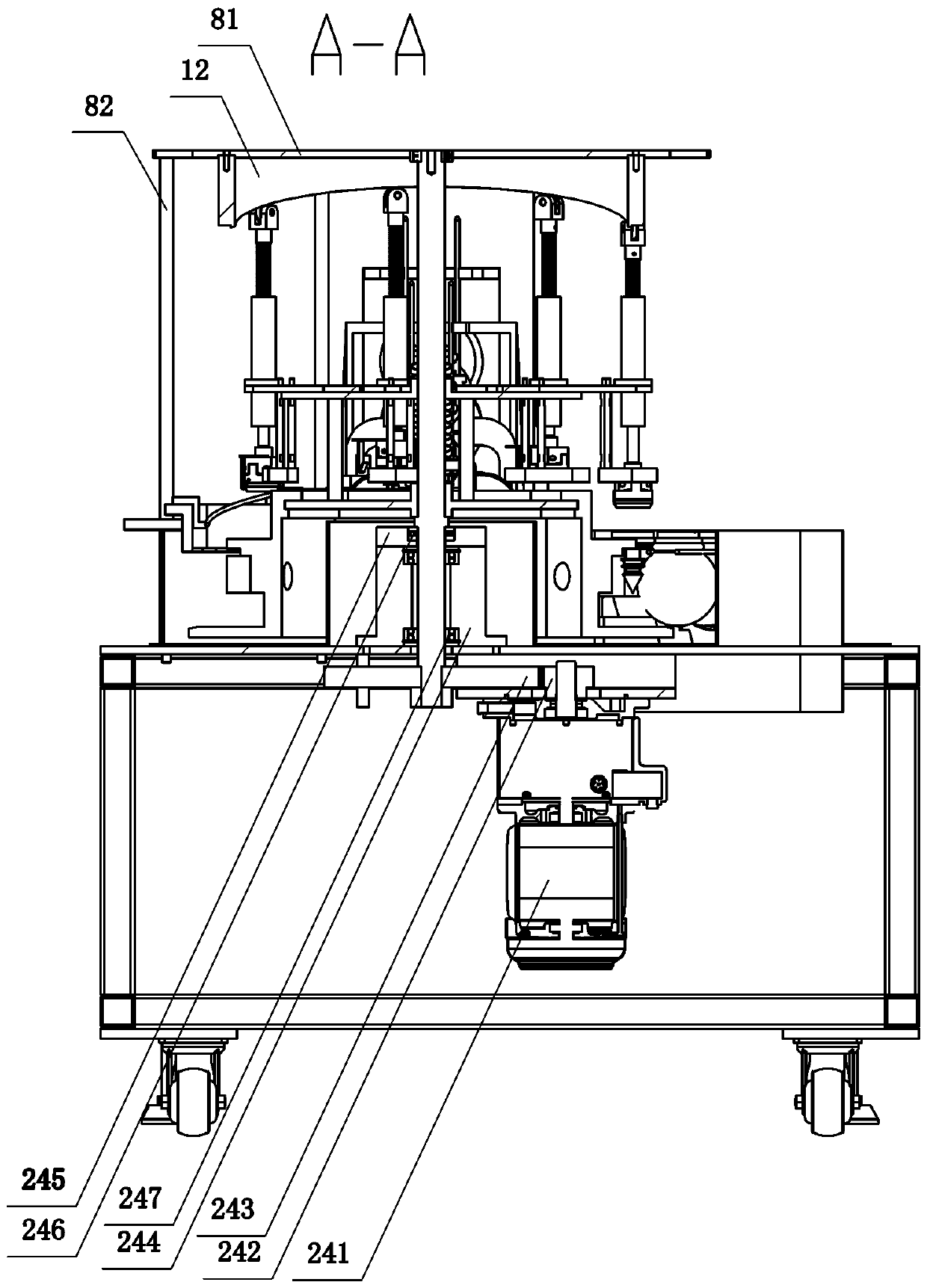

[0031] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 . A device for automatic pressing of multi-standard crystal balls and ceramic interiors, including

[0032] Workstation support mechanism 1, which includes a workstation base 11 and a cam plate 12 installed above the workstation base 11, the interior of the workstation base 11 contains water, and the slope 121 on the lower side of the cam plate 12 gradually decreases from its front end to the rear;

[0033] A flexible turntable mechanism 2, which is rotatably installed on the workstation base 11, has a plurality of crystal ball accommodation stations 20 arranged in an annular array on the flexible turntable mechanism 2;

[0034] A plurality of floating tensioning mechanisms 3 are installed on the flexible turntable mechanism 2 in an annular array, and the pluralit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com