Full-automatic multi-cylinder sock washing machine

A sock washing machine, fully automatic technology, applied to washing machines with containers, washing devices, textiles and papermaking, etc., can solve the problem of bacteria getting to other parts of the body, save detergent and water, avoid waste of resources, volume small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

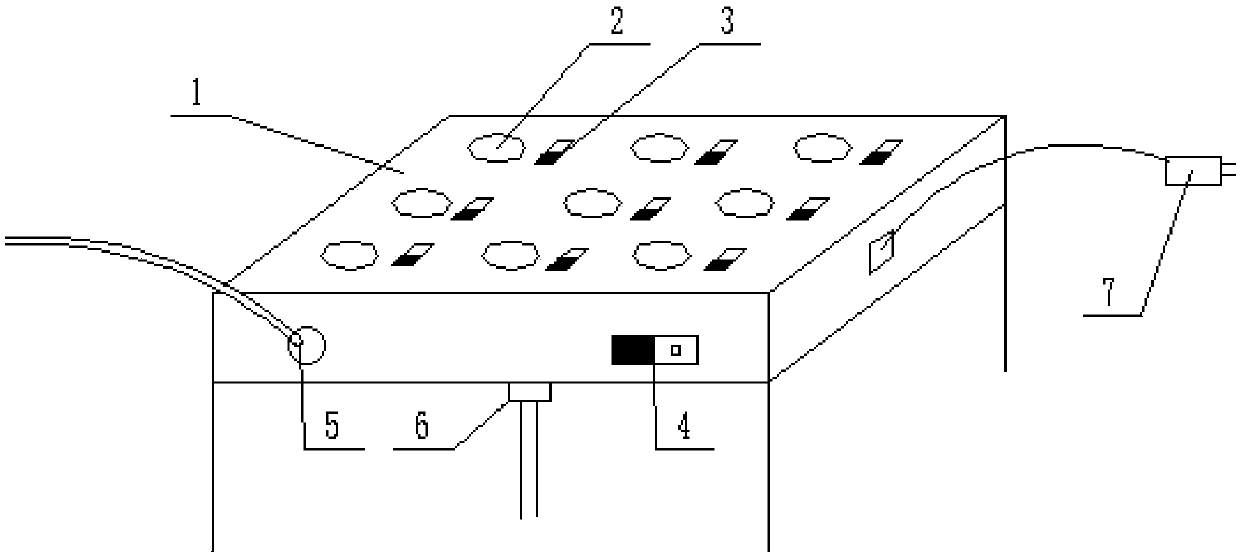

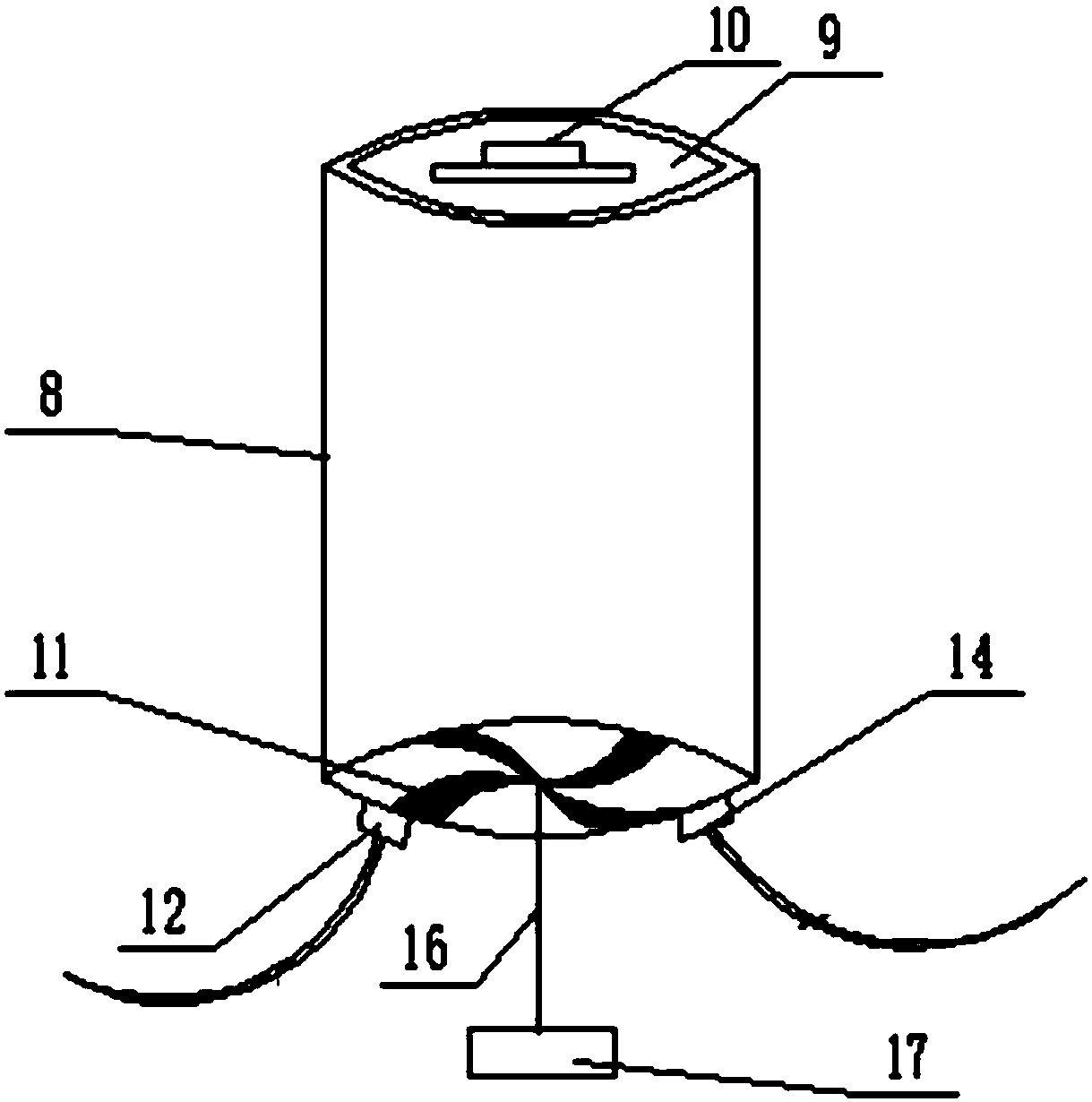

[0013] see figure 1 , figure 2 , the present invention provides a technical solution: a full-automatic multi-tube sock washing machine, including a base 1, on which 5-20 sock washing tubes 2 are arranged, and the sock washing tube 2 consists of a cylinder body 8. There is a cylinder cover 9 on the top of the cylinder body 8, and a pulsator 11 is arranged at the bottom of the cylinder body 8, and the pulsator 11 is connected with the motor 17 arranged below the cylinder body 8 through a drive shaft 16; A water inlet pipe 12 and a drain pipe 14 with electronic valves; a main water inlet pipe 5, a switch 4 and a power plug 7 are arranged on the base 1, and a main drain pipe 6 is arranged at the bottom of the base 1; the main water inlet pipe 5 and all The water inlet end of wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com