Head portion folding device for plastic bags

A folding device and plastic bag technology, applied in packaging, paper product packaging, transportation and packaging, etc., can solve the problems of large machine volume, affecting folding speed, complex structure, etc., to achieve the effect of compact overall structure and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

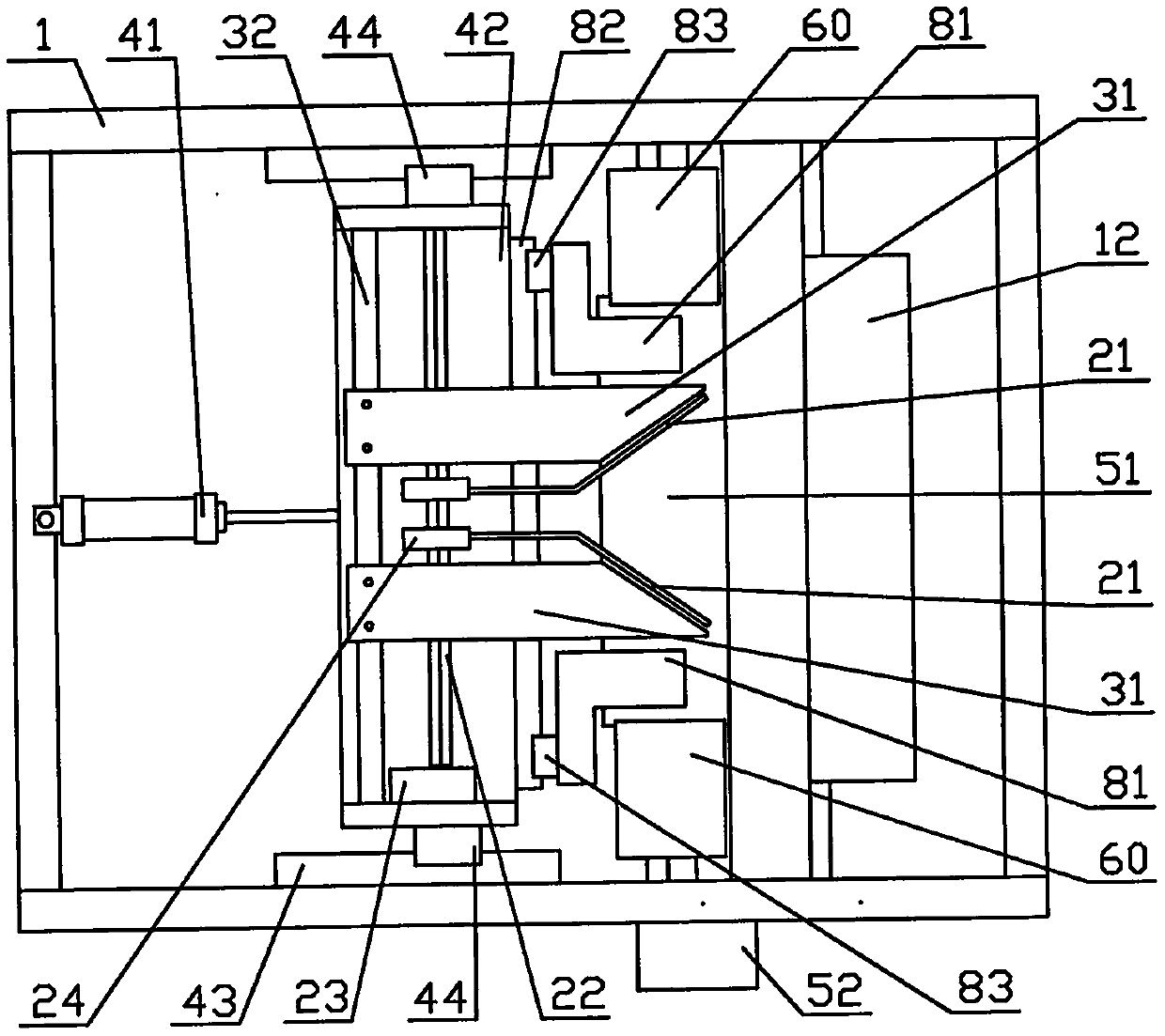

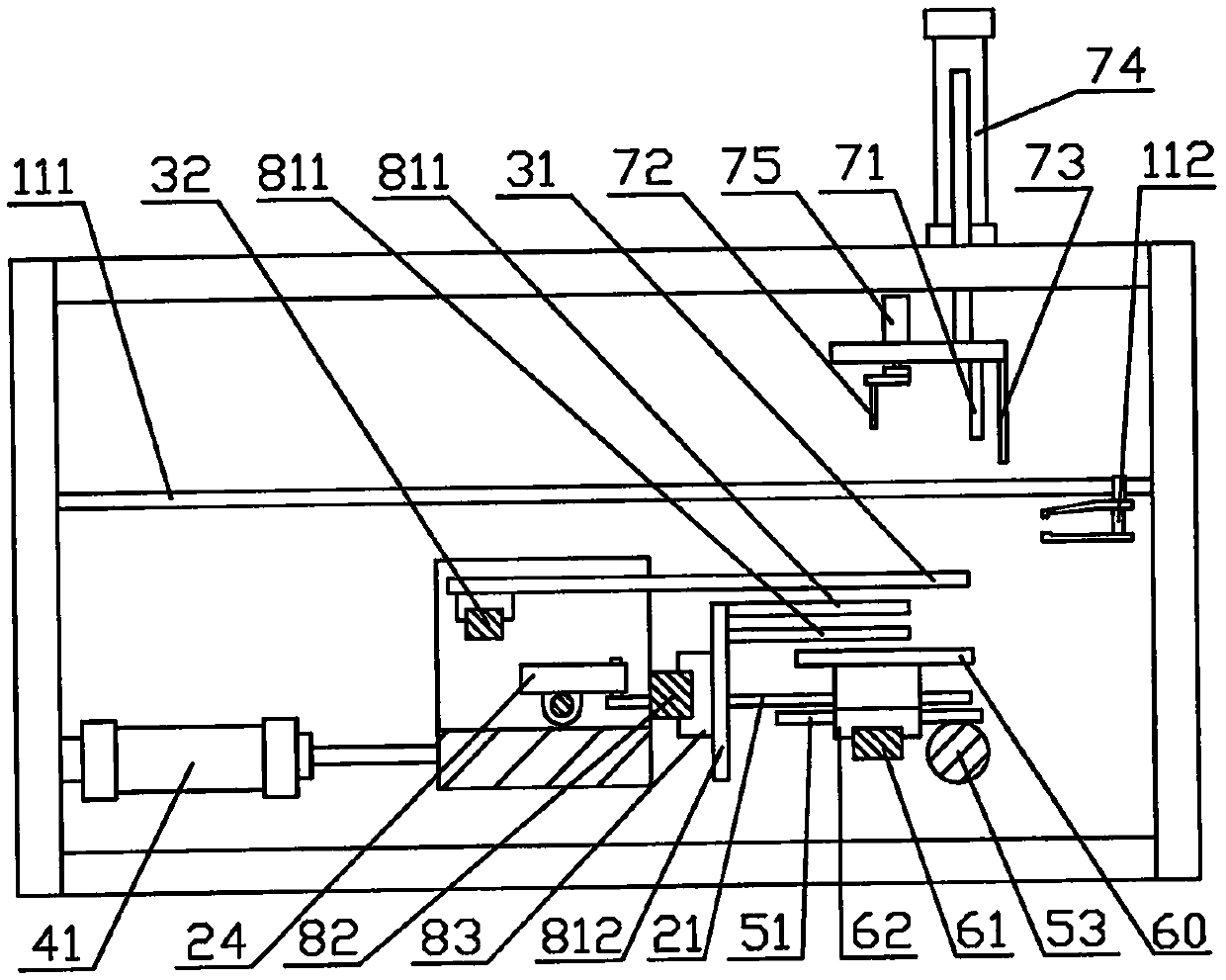

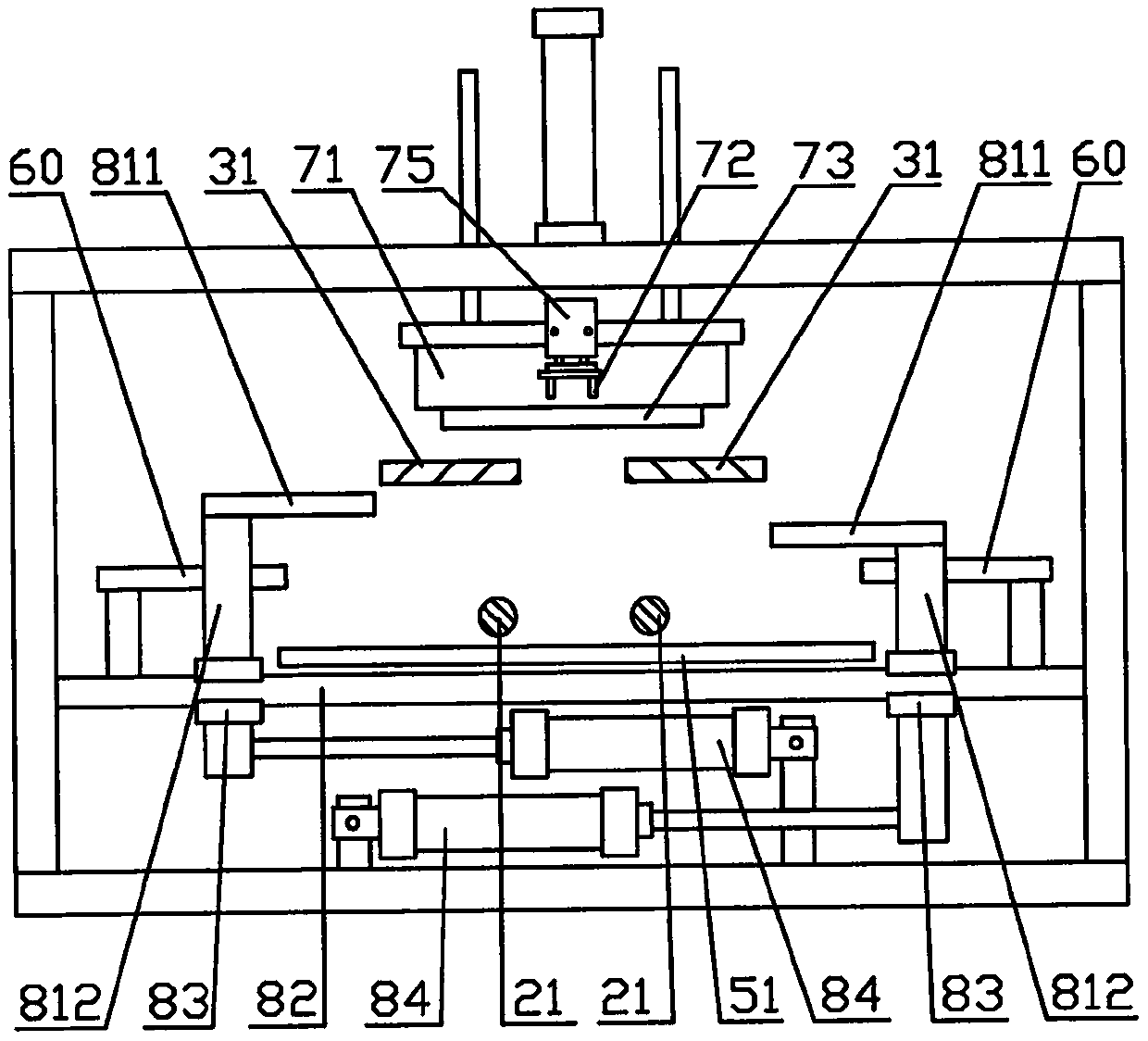

[0024] Such as Figure 1 to Figure 10 Shown, the left side of accompanying drawing is exactly the front described in the present invention, and the right side of accompanying drawing is exactly the described back of the present invention; The top of accompanying drawing is exactly the right side described in the present invention, and the following of accompanying drawing is exactly the left side described in the present invention . In order to fully disclose the technical solutions of the present invention, the present invention will be specifically described below through examples.

[0025] Examples such as figure 1 , figure 2 , image 3 Shown: install a tray rack slide rail 43 front and rear respectively on both sides of the front part of the frame 1, set a tray rack 42, install a slider 44 respectively on the left and right sides of the tray rack 42, make the tray rack 42 pass through the slider 44 is slidably installed on two pallet frame slide rails 43, and a cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com