Column foundation cup mouth core formwork anti-floating device and construction method

A column foundation and mandrel technology, which is applied in the field of anti-floating device for the cup mouth mandrel of the column foundation, can solve the problems of inconvenient construction, increased cost, labor and time consuming, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

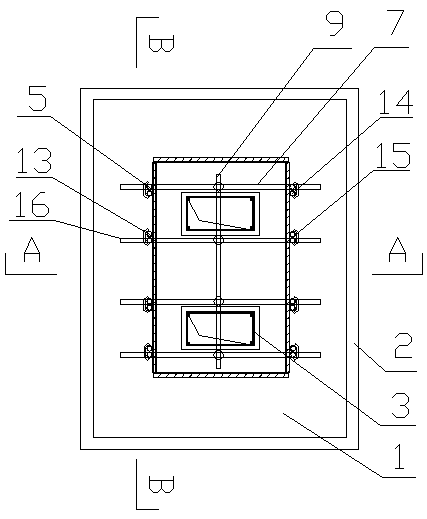

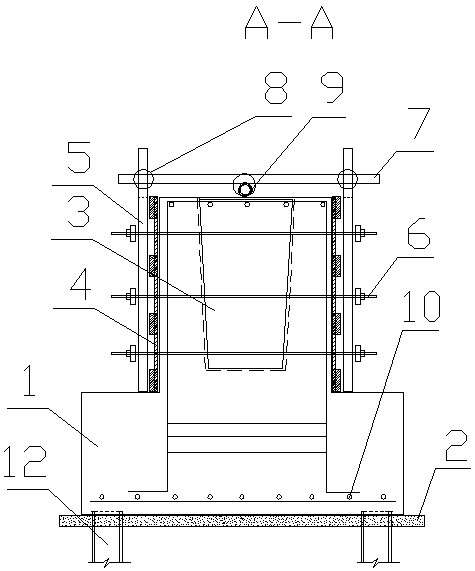

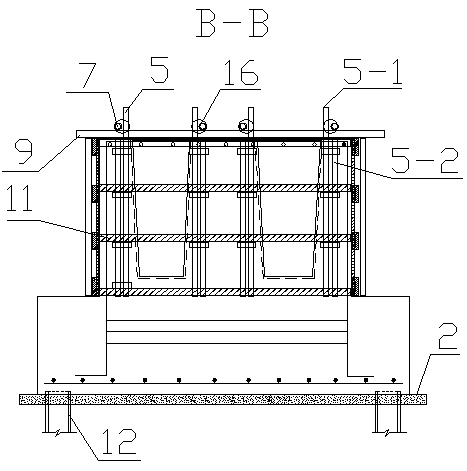

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0028] see figure 1 , figure 2 , image 3 , an anti-floating device for a column foundation cup mouth mandrel, which consists of a column foundation 1, a cushion layer 2, a mandrel 3, a template 4, a template back group 5, a tension screw 6, a cross bar 7, a right-angle fastener 8, Anti-floating rod 9, foundation reinforcement, wooden square keel 11 and pile 12 constitute. Above the pile 12 is a cushion layer 2 , above the cushion layer 2 is a column foundation 1 , and foundation steel bars 10 are laid in the column foundation 1 .

[0029] The upper part of the column foundation 1 is installed with a rectangular formwork 4 with a cross-section, and a mandrel 3 is installed in the formwork 4. In the present embodiment, the mandrel 3 is two pieces, and a wooden square keel 11 is installed in the formwork 4. The two sides of formwork 4 are respectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com