Moisture-proof laminate floor

A technology for strengthening floors and bottom plates, applied in the field of floor products, can solve the problems that the floor has no waterproof function and cannot be heated, and achieves the effect of improving the use efficiency and quick heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

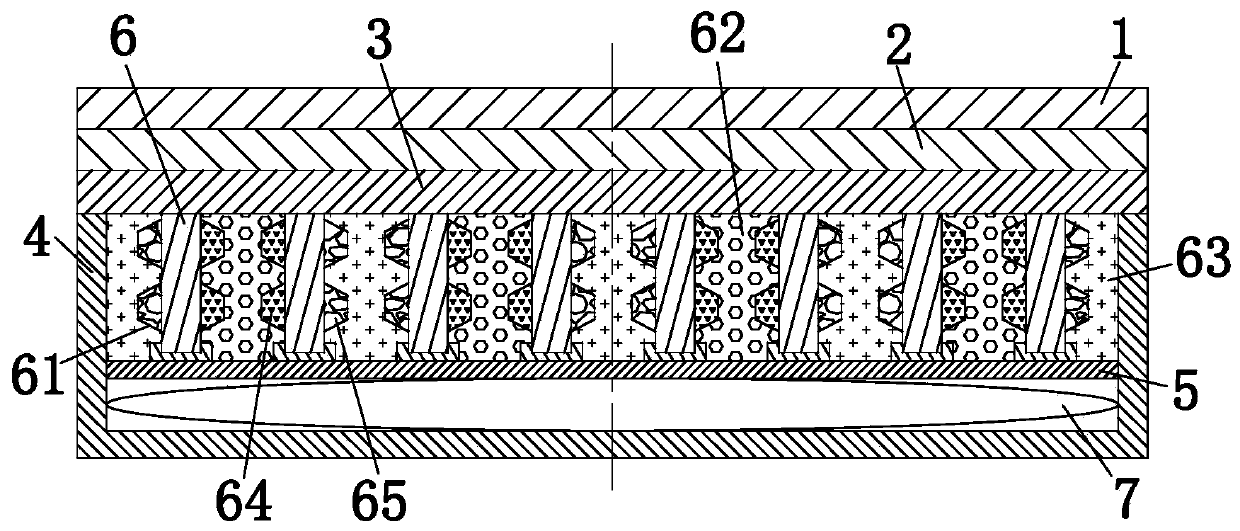

[0020] use Figure 1-Figure 4 A moisture-proof laminate flooring according to one embodiment of the present invention will be described below.

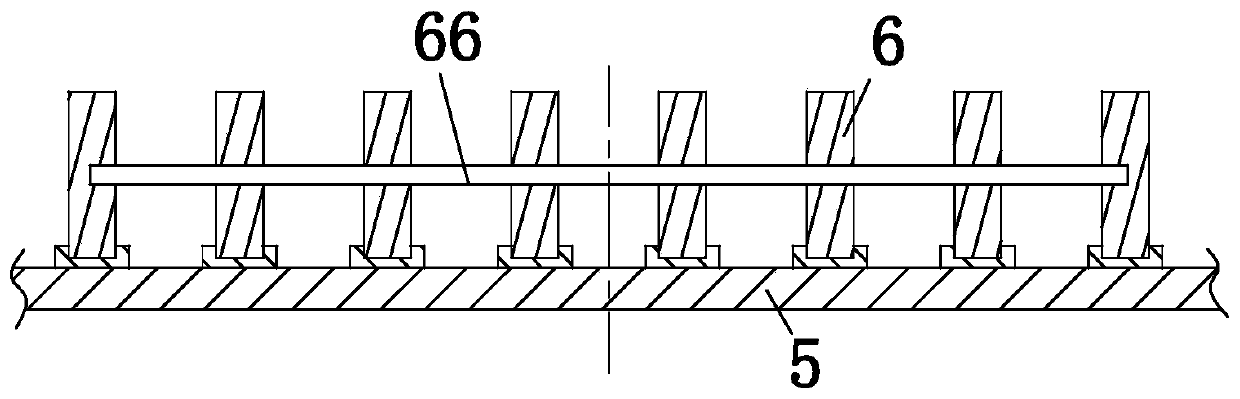

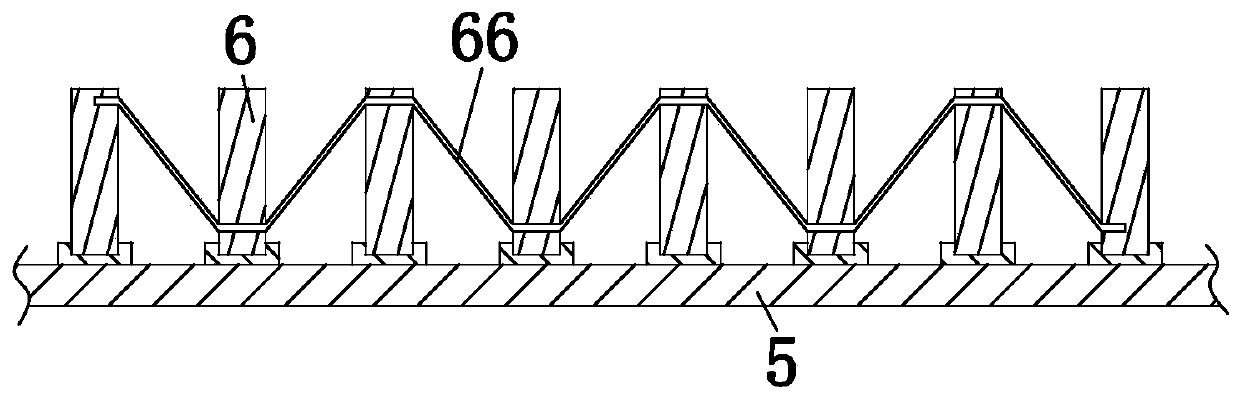

[0021] like Figure 1-Figure 4 As shown, a moisture-proof reinforced floor according to the present invention includes a decorative layer 1, a wear-resistant layer 2, a moisture-absorbing layer 3, and a bottom plate 4; the decorative layer 1 is arranged on the uppermost layer, and the lower end of the decorative layer 1 is fixedly connected with a wear-resistant layer 2; the lower end of the wear-resistant layer 2 is fixedly connected with a moisture-absorbing layer 3; the lower end of the moisture-absorbing layer 3 is fixedly connected with a bottom plate 4; the inner lower end of the bottom plate 4 is provided with an elastic layer 5; the upper surface of the elastic layer 5 is evenly fixed A mounting plate 6 is provided; friction plates 61 are fixedly installed on the left and right ends of the mounting plate 6, and the gap betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com