Parallel and adjustable-frequency negative-stiffness vibration absorbing device

A vibration damping device and negative stiffness technology, which is applied in the direction of shock absorbers, shock absorber-spring combinations, shock absorbers, etc., can solve the problems of precision instruments that cannot meet the requirements, and achieve the effect of a stable working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

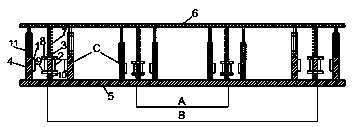

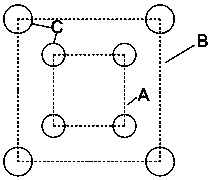

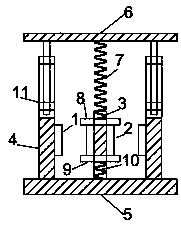

[0026] combine figure 1 and figure 2 , figure 1 Shown is the front view of the parallel frequency-adjustable negative stiffness damping device of the present invention, figure 2 Shown is the top view of the parallel frequency-adjustable negative stiffness vibration damping device of the present invention. In order to achieve the purpose of frequency-adjustable vibration damping for the specific frequency vibration of the instrument, according to the requirements for the vibration damping frequency of the required load-bearing precision instrument, each of the inner and outer rectangular circles The stiffness of the upper mechanical spring 7 of the substructure C and the damping coefficient of the ordinary damping member 11 are set differently, so as to realize the purpose of vibration reduction for specific frequency vibration of the ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com