Node deviation measuring instrument and node deviation measuring method

A technology of deviation measurement and measurement method, which is applied in the field of shipbuilding and can solve the problems of lack of versatility and many sizes and specifications.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

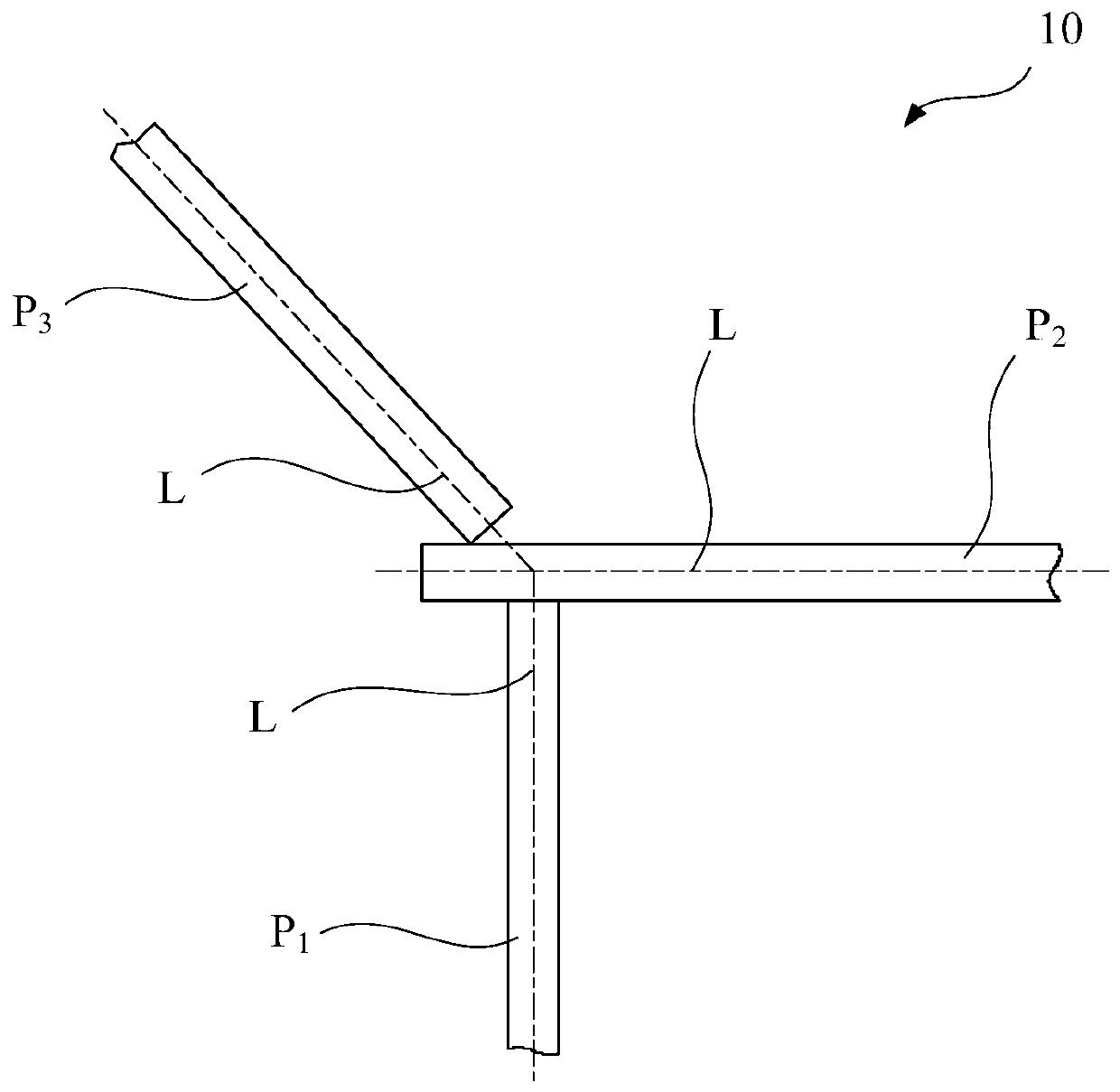

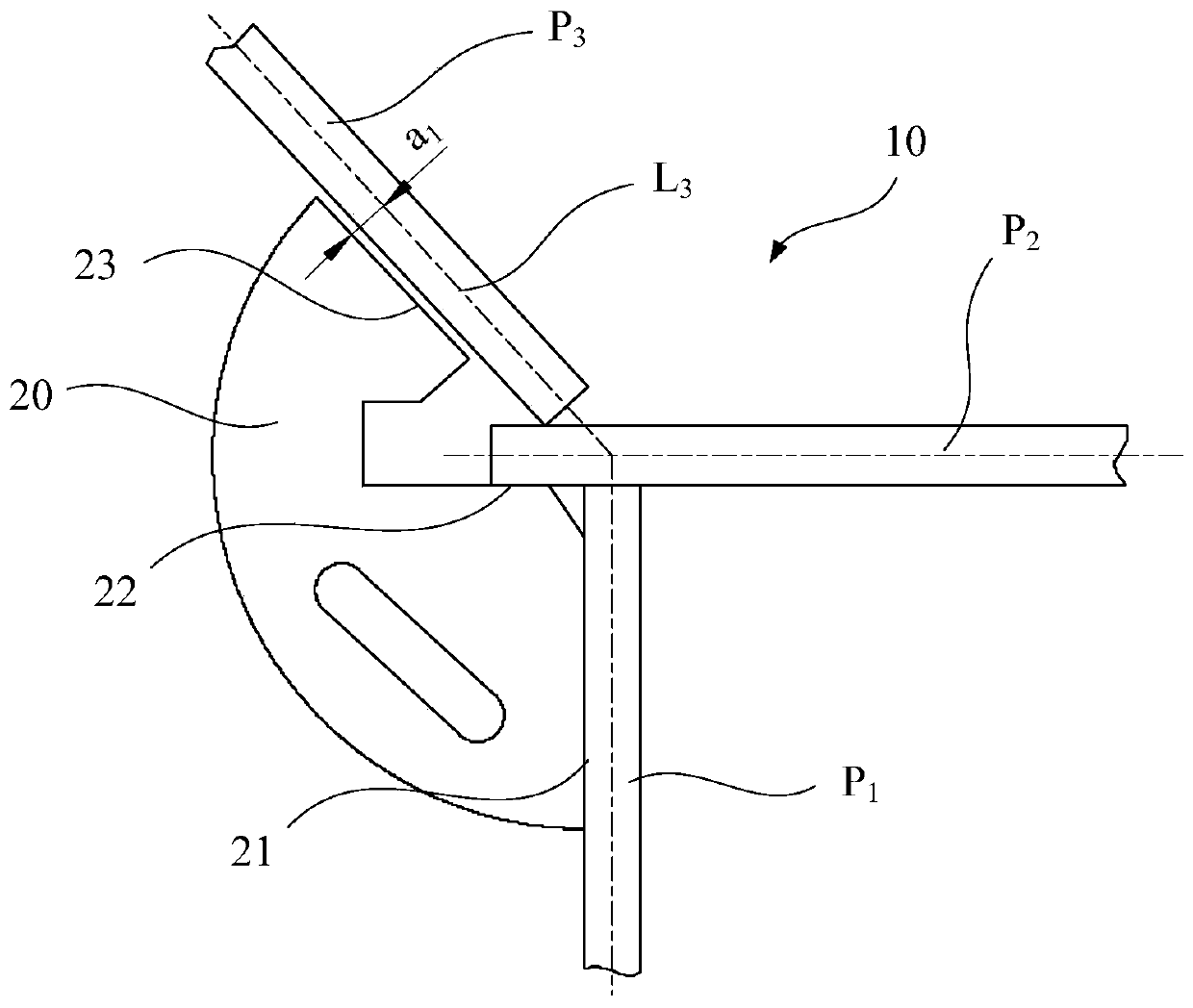

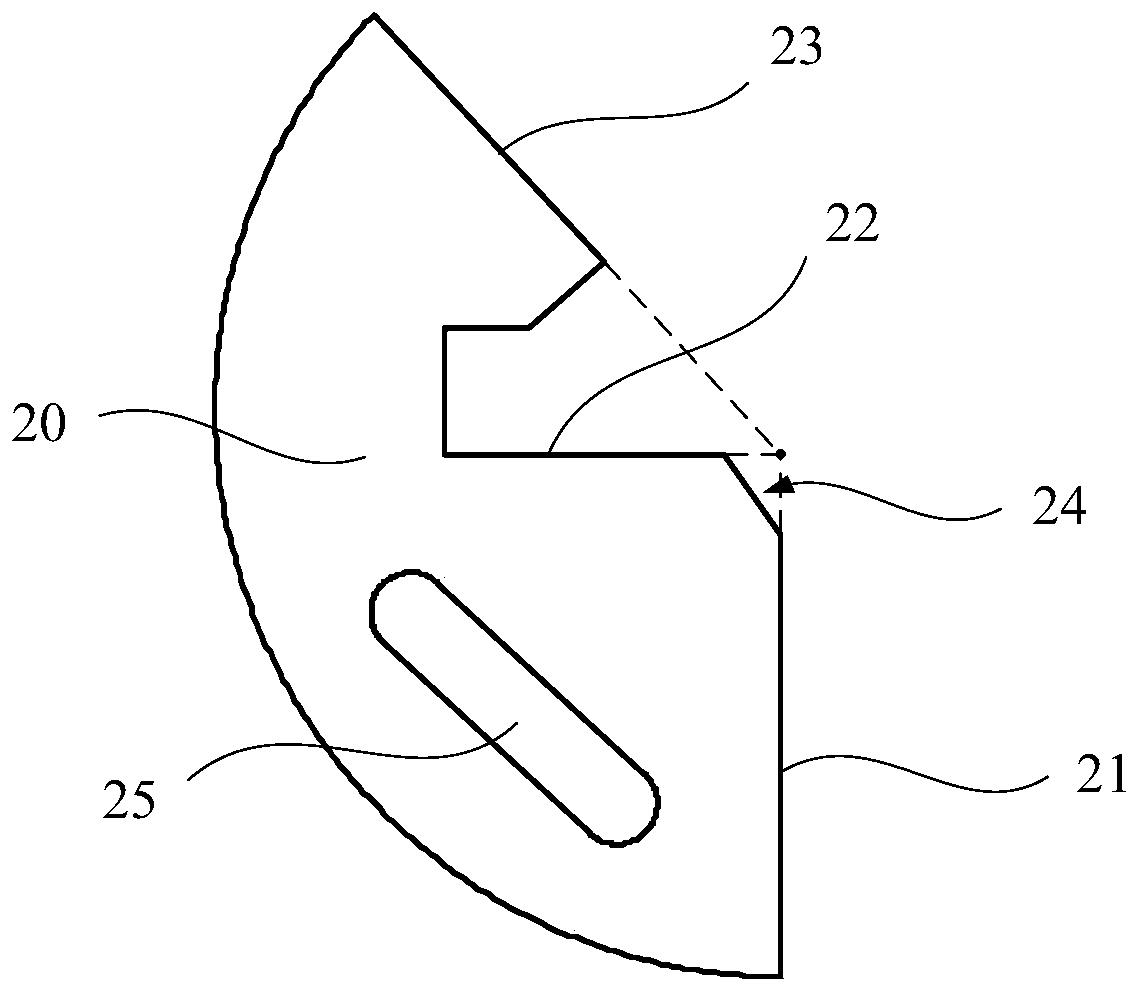

[0065] Such as figure 2 and image 3 As shown, the present invention provides a node deviation measuring instrument 20, which is used to measure the deviation of the cross joint 10. The node deviation measuring instrument 20 has a first reference edge 21, a second reference edge 22, a measurement reference line and a measurement edge twenty three. Wherein, the first reference edge 21 is used to abut against the first plate P of the cross joint 10 1 On the surface, the second reference edge 22 is used to abut against the second plate P of the cross joint 10 2 On the surface of , the measurement reference line is along the third plate P parallel to the cross joint 10 3 The center line L 3 Set, and the extension line of the measurement reference line intersects the intersection of the first reference edge 21 and the second reference edge 22, and the measurement edge 23 of the node deviation measuring instrument 20 coincides with the measurement reference line.

[0066] The ...

Embodiment 2

[0083] Such as image 3 , Figure 4 and Figure 6 As shown, this embodiment also provides a method for measuring the node deviation, which is used to measure the deviation of the cross joint 10. This method also uses the node deviation measuring instrument 20 as described in Embodiment 1. The specific steps of the method are as follows :

[0084] S201. Obtain the first plate P of the cross joint 10 to be measured 1 Thickness t 1 , the second board P 2 Thickness t 2 , the third board P 3 Thickness t 3 , the first board P 1 with the second plate P 2 The included angle β and the second plate P 2 with the third plate P 3 The included angle θ;

[0085] S202. Pass the first board P 1 Thickness t 1 , the second board P 2 Thickness t 2 , the third board P 3 Thickness t 3 , the first board P 1 with the second plate P 2 The included angle β and the second plate P 2 with the third plate P 3 Calculate the angle θ of the third plate P 3 The deviation reference value ...

Embodiment 3

[0094] This embodiment also provides a node deviation measuring instrument 20, which has roughly the same structure as that of the node deviation measuring instrument in Embodiment 1. The difference is that, in this embodiment, the measuring edge 23 of the node deviation measuring instrument 20 It is not coincident with the measurement reference line 231, but is arranged parallel to the measurement reference line 231 on the side away from the third plate. That is, the measuring edge 23 is kept parallel to the measuring reference line 231 , therefore, in the formula for calculating the deviation reference value a, the value of the distance z is not 0.

[0095] Specifically, in the cross joint 10 measured by the node deviation measuring instrument 20, the thickness t of the third plate 3 greater than the thickness t of the first plate 1 , or the thickness t of the second plate 2 When using the nodal deviation measuring instrument 20 provided by Embodiment 1, the following situ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com