Method for manufacturing temperature sensor and temperature sensor

A technology of temperature sensor and manufacturing method, applied in thermometer parts, thermometers, thermometers using directly heat-sensitive electrical/magnetic components, etc., can solve the problem of poor stability and low thermal conductivity of epoxy resin, which can only reach 150 ℃ and other problems, to achieve the effect of strong stability and good waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

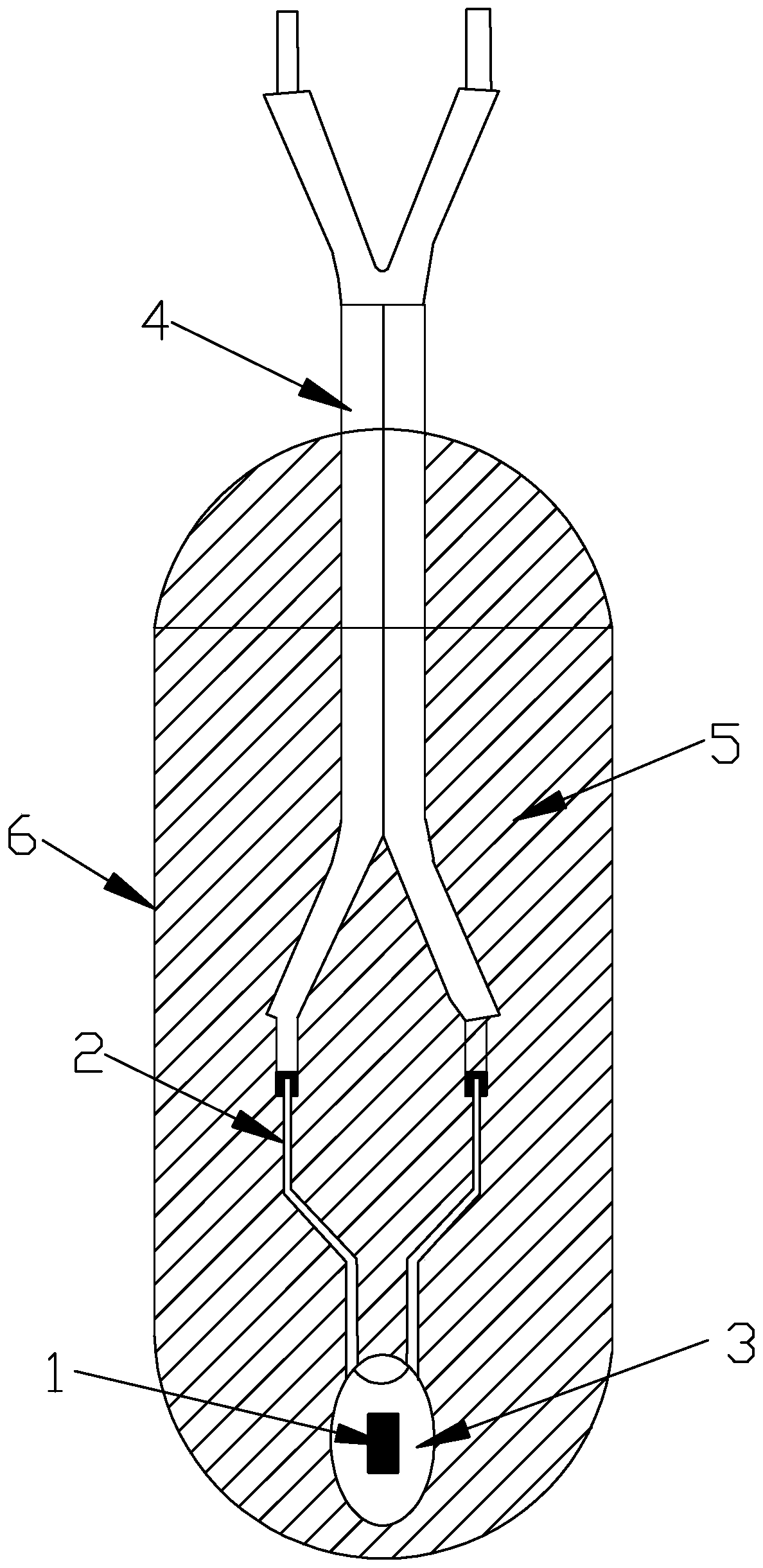

[0019] see figure 1 Shown: a temperature sensor, including a thermistor chip 1, lead wire 2, encapsulation layer 3, electronic wire 4, perfusion sealing layer 5, metal shell 6, thermistor chip 1 is an NTC thermistor chip, two The terminal electrodes are welded to the lead wires 2 respectively, the surface of the thermistor chip 1 is covered with the encapsulation layer 3, the lead wire 2 is fixedly connected to the electronic wire 4, and the metal casing 6 covers the thermistor chip 1, lead wire 2, and partly covered with metal On the outside of the electronic wire 4 in the housing, a potting sealing layer 5 is fixed between the thermistor chip 1 and the metal housing 6 .

[0020] The present invention provides a method for making the above-mentioned temperature sensor, comprising the following steps:

[0021] Step 1: Take the required type of thermistor chip 1 and the metal shell 6 with a cavity inside for use;

[0022] Step 2: spot welding the lead wire 2 on the thermistor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com