Thick plate blank macrosegregation calculation method based on blank shell bulging and mechanical pressing

A calculation method and macro-segregation technology, applied in the direction of calculation, complex mathematical operations, special data processing applications, etc., can solve the problems that affect the accuracy of casting slabs and cannot accurately describe the shape of slab shell bellies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

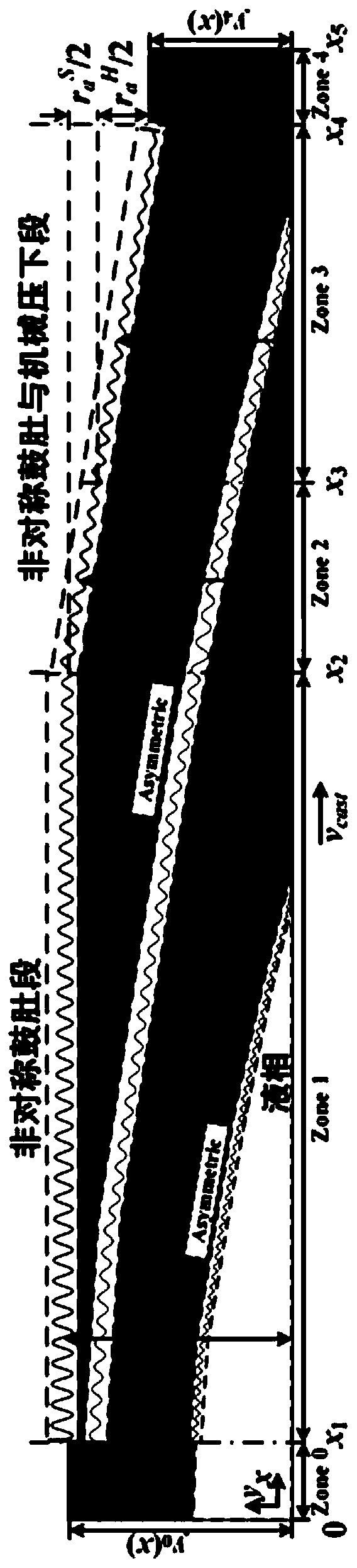

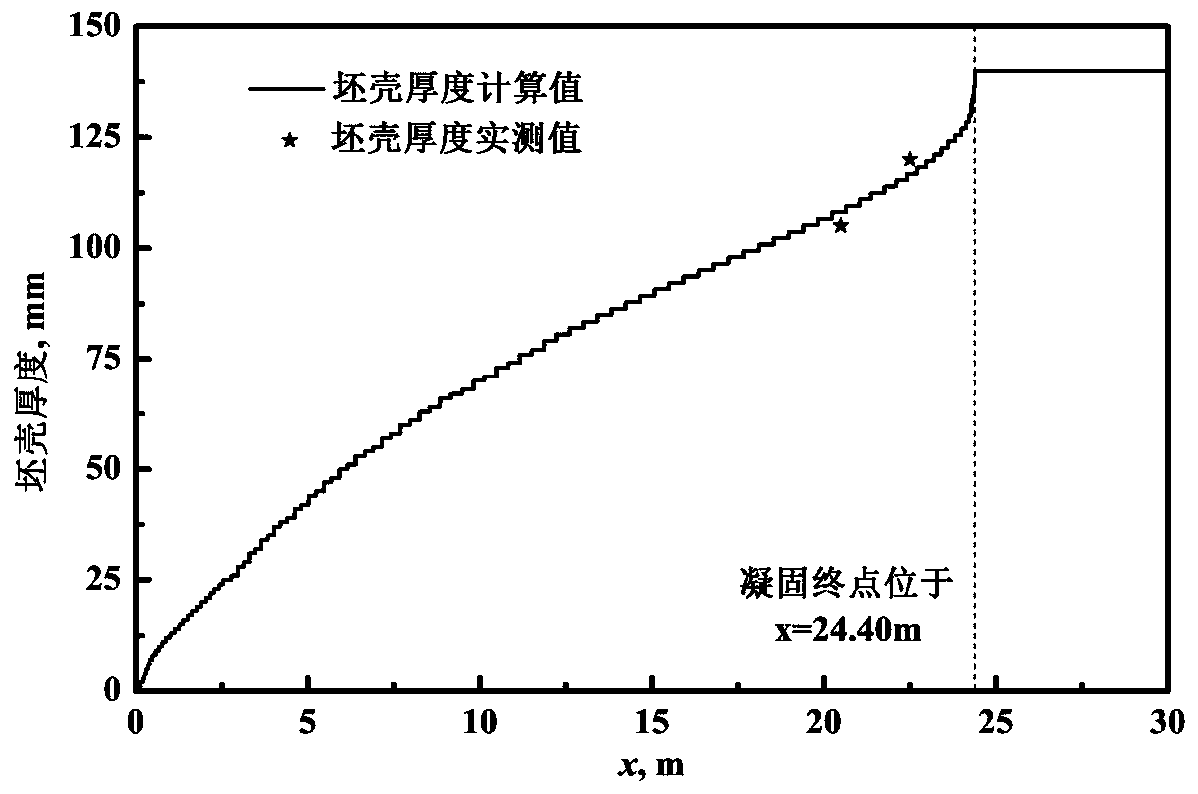

[0062] Such as figure 1 As shown, for the solidification process of continuous casting thick slabs, this example establishes a geometric calculation model that considers the deformation of the actual slab shell bulging and the mechanical pressing process at the end of solidification. In order to save storage space and calculation amount, the longitudinal section of the actual slab along the direction of casting stream is processed symmetrically. In this geometric model, the initial thickness of the thick slab is 140 mm, and the length of the continuous casting calculation zone is 30,430 mm. The number of grids in the entire calculation area is about 3,400,000, and the size of each grid is 5mm 2 . Combined with the actual on-site production, the corresponding vertical area division parameters of the model are shown in Table 3;

[0063] Table...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com