Auxiliary tool for welding cable

An auxiliary tool and welding cable technology, which is applied in the direction of circuits, connections, electrical components, etc., can solve the problems of poor welding quality, burns of welding personnel, and turning into liquid, so as to eliminate hidden dangers of accidents, improve work efficiency, and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

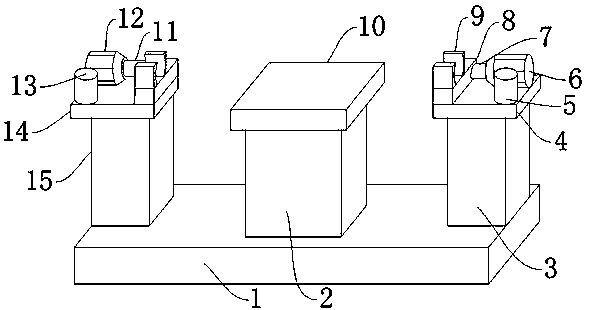

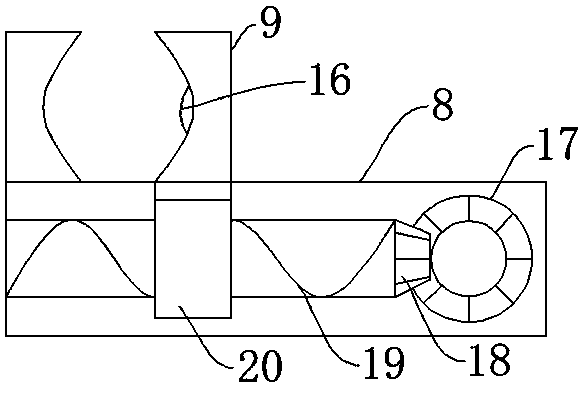

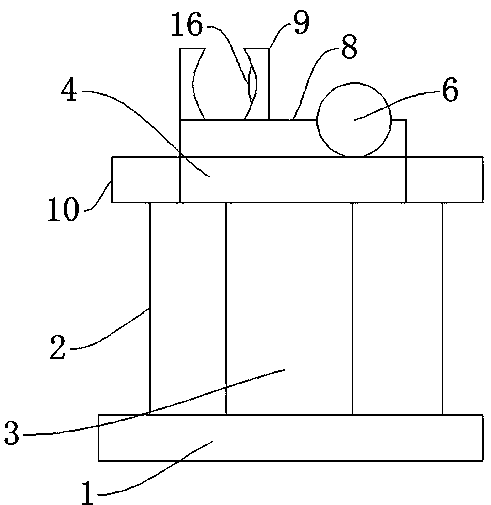

[0027] combine Figure 1-Figure 4 As shown, the specific structure of an auxiliary tool for welding cables is: including a base 1, a welding table 10, a semicircular buckle 9, a first motor 6, and a second motor 12, and the upper end of the base 1 is provided with a first support column 2 for use To support the welding platform 10, the first support column 2 is provided with a second support column 3 on one side, used to support the first fixed platform 4, and the first support column 2 is provided with a third support column 15 away from the second support column 3. To support the second fixed platform 14, the upper end of the first support column 2 is provided with a welding platform 10, which is used to place welding cables. The upper end of the second support column 3 is provided with a first fixed platform 4, and the upper end of the first fixed platform 4 is provided with The first control switch 5, the first motor 6 of model Y315L1-10 is provided on the rear side of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com