Nozzle bar for fiber processing with water jet

A nozzle beam, water jet technology, applied in the direction of jetting device, jetting device, textile and papermaking, etc., can solve problems such as increased pressure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

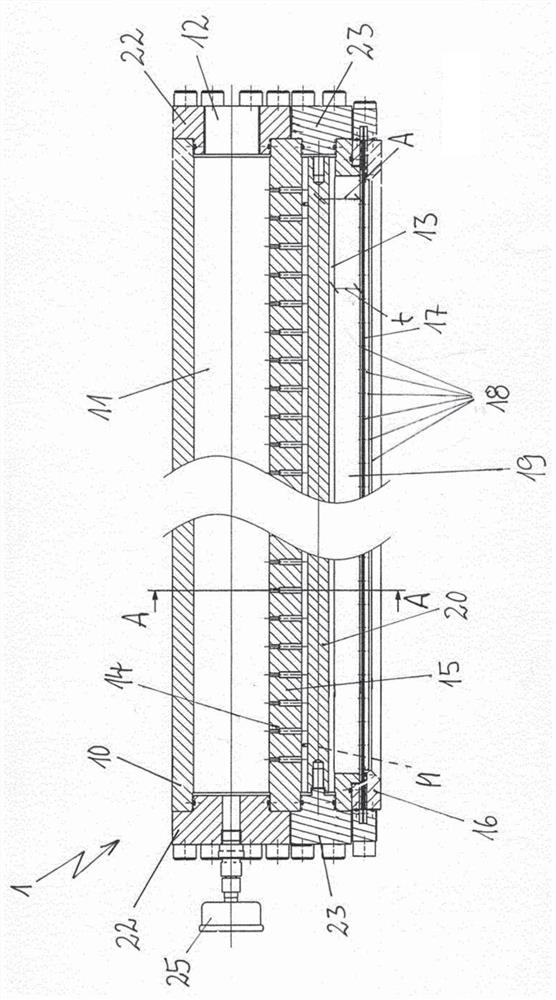

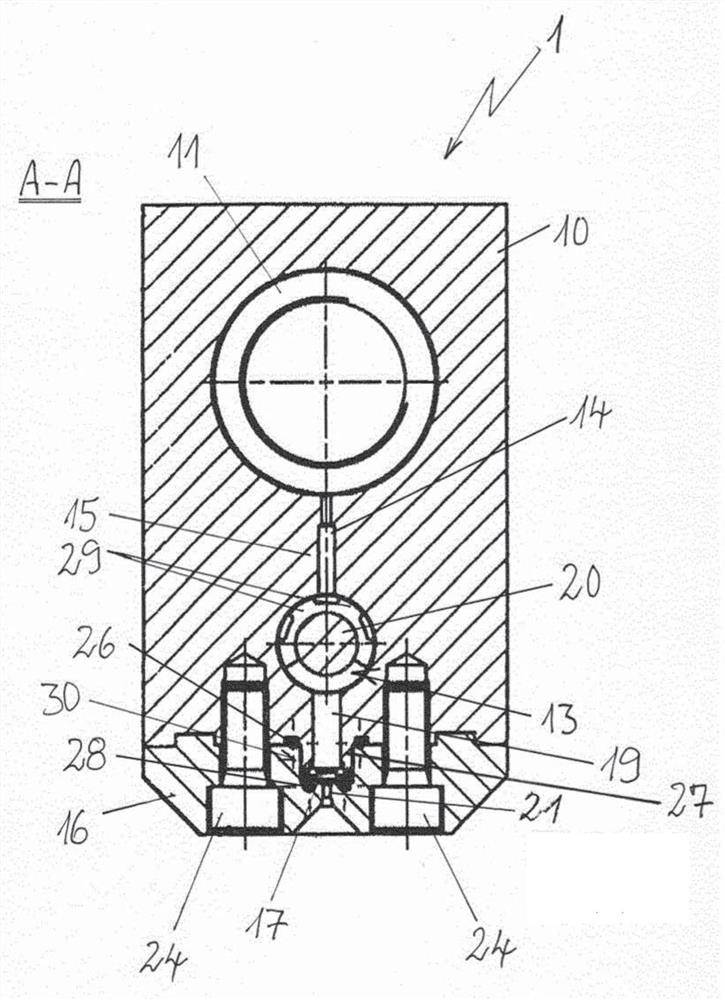

[0021] figure 1 shows a cross-sectional view of a nozzle bar 1 for processing fibers, such as textile webs, with water jets, and figure 2 Shows a sectional view of the nozzle beam 1 along the section line A-A, wherein the section line A-A intersects figure 1 nozzle beam. Combine below figure 1 and figure 2 The nozzle beam 1 will be further described.

[0022] The housing of the nozzle bar 1 has an upper part 10 which is screwed to a lower part 16 multiple times over its length by means of threaded fasteners 24 . The upper part 10 has two longitudinally extending perforations 11 and 13 , wherein the upper perforation 11 forms a pressure chamber and the lower perforation forms a pressure distribution chamber 13 . The pressure chamber 11 and the pressure distribution chamber 13 are open at the end of the upper part 10 and the pressure chamber 11 and the pressure distribution chamber 13 are closed liquid-tight with the closing element 22 and 23 . The closing element 22 for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com