Waterproof structure of culvert and construction method thereof

A waterproof structure and culvert technology, applied in the field of culvert waterproofing, can solve the problems of affecting the traffic in the cave, reducing the life of the culvert, difficult to achieve sealing and waterproofing, etc., to achieve the effect of simple construction and installation, improved waterproof performance, and improved drainage effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

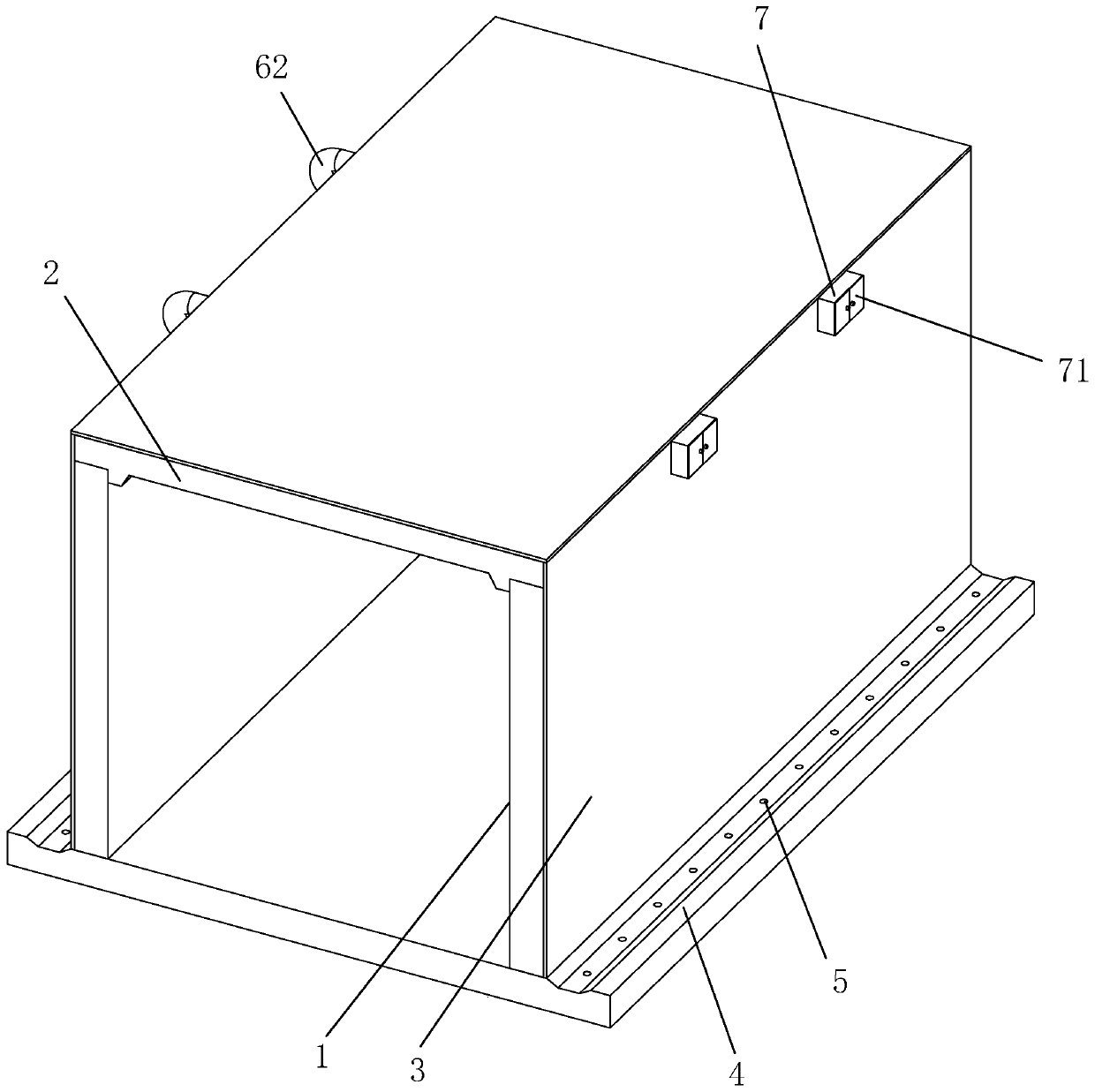

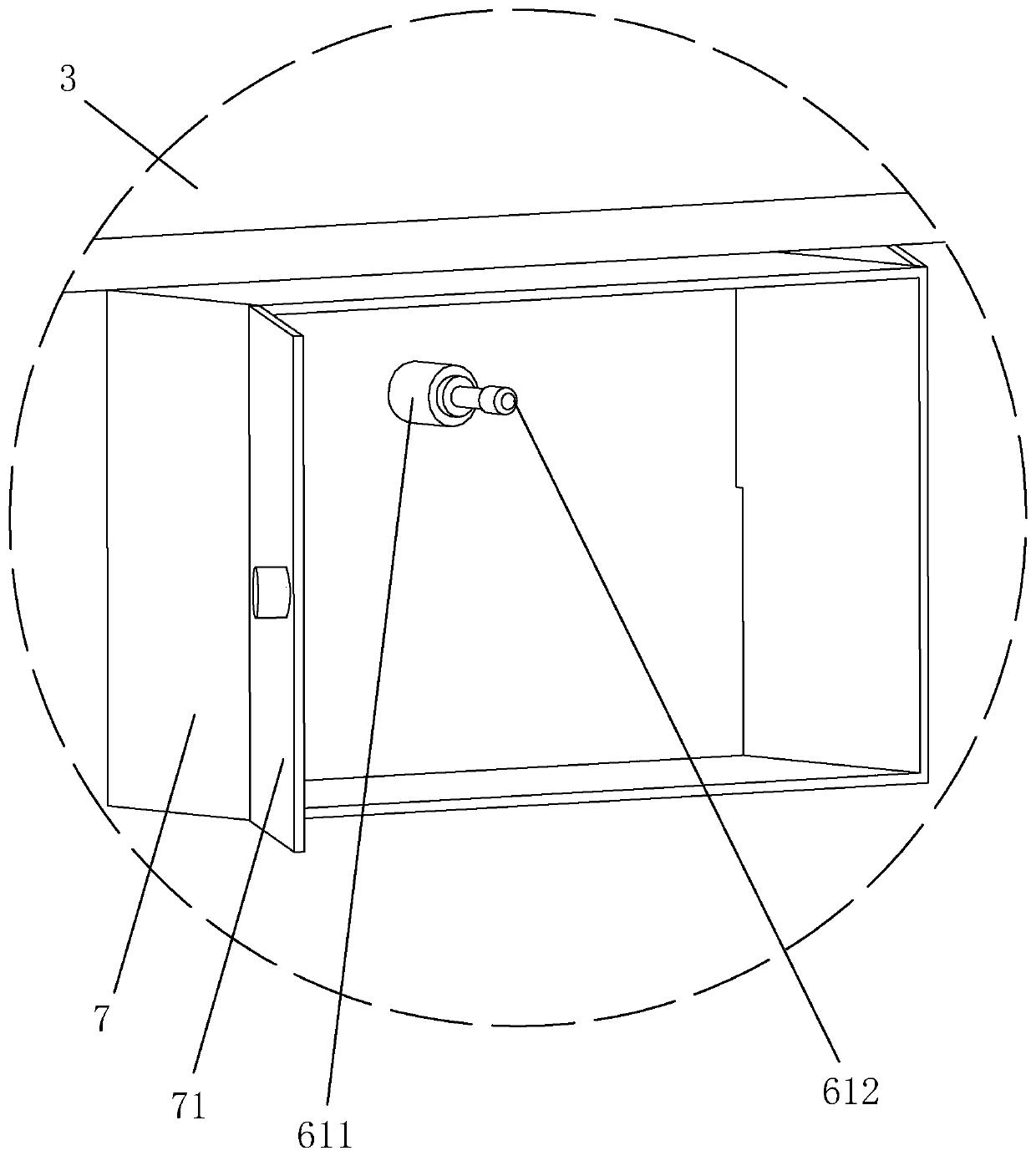

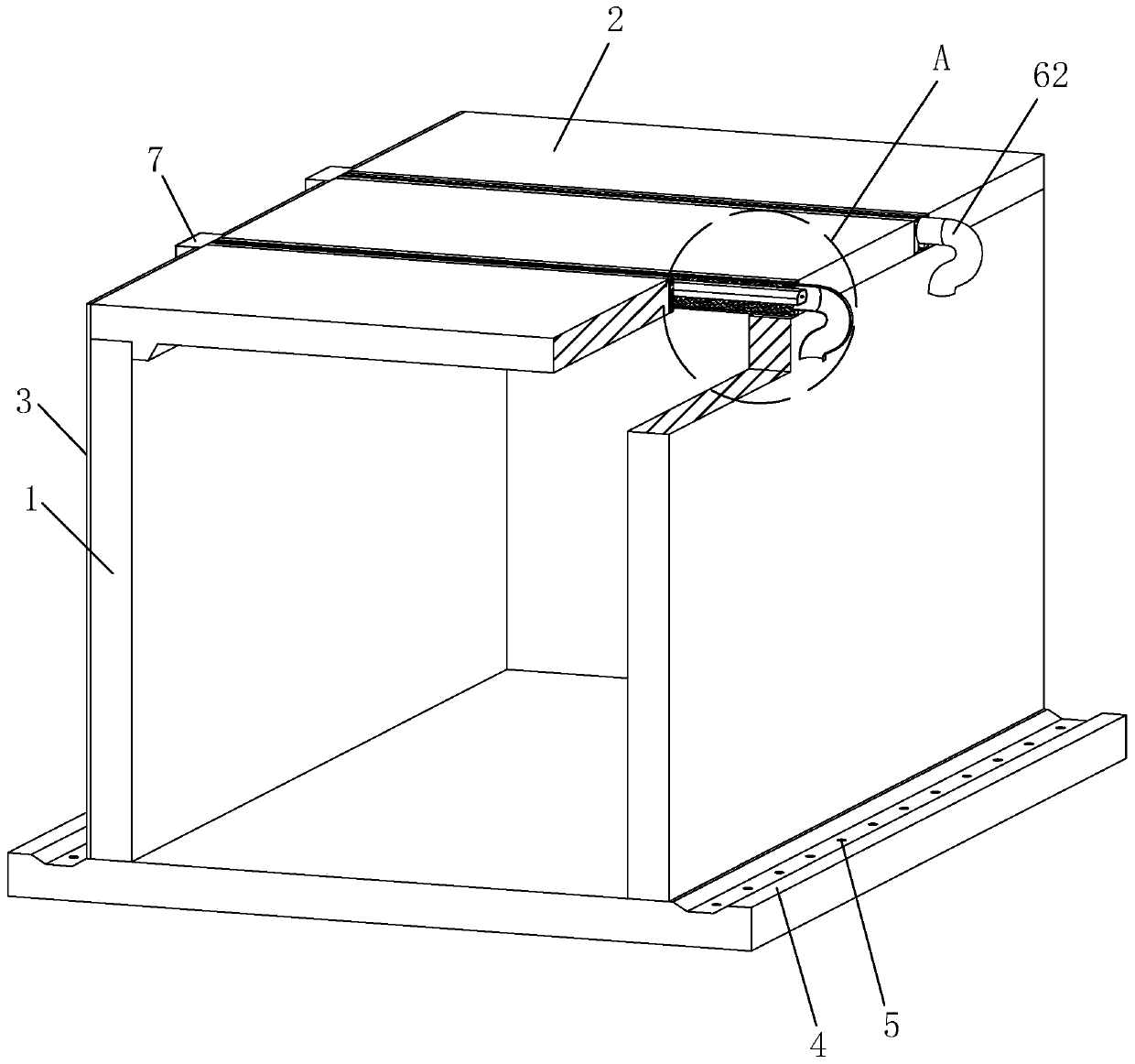

[0037] This embodiment 1 discloses a culvert waterproof structure, which is suitable for reinforced concrete cover culverts, such as figure 1 As shown, it includes two side walls 1 covering the body, a plurality of cover plates 2 covering the top of the side walls 1, a deformation joint waterproof structure arranged between adjacent cover plates 2, and covering the side walls 1 and cover plates 2 The waterproof board 3 on the outside, the bottom of the side wall 1 is provided with a drainage ditch 4, and a drainage hole 5 is dug in the drainage ditch 4, and the drainage hole 5 goes deep into the ground, so that the water in the drainage ditch 4 can be discharged into the ground. Such as figure 2 and Figure 5 As shown, the deformation joint waterproof structure includes a rubber air bag 61 and a drain pipe 62 that can be repeatedly inflated and deflated. The length direction of the rubber air bag 61 is consistent with the length direction of the gap between the cover plates ...

Embodiment 2

[0043] This embodiment 2 discloses a construction method of the culvert waterproof structure of embodiment 1, including the following process steps:

[0044] 1. Dig a foundation pit to the ground, pour concrete into the foundation pit on site, drop the side wall 1 into the foundation pit, and fix the side wall in the foundation pit through the poured concrete, and stand upright on the ground;

[0045] 2. Install the cover plate 2 on the top of the two side walls 1, anchor the steel bars at the connection between the cover plate 2 and the side wall 1, and fill in C30 micro-expanded fine stone concrete; A C-shaped channel steel 8 is pre-anchored on the side, and the notch of the channel steel 8 faces the outside of the cover plate 2, that is, it is set facing the gap between the cover plates 2; rubber is bonded in the segmental gap formed by multiple cover plates 2 Airbag 61, the bonding method is to apply BD803 rubber-metal adhesive in each channel steel 8, fill the rubber airb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com