Full-automatic weighing type fruit sorting device

A sorting device and fully automatic technology, applied in sorting and other directions, can solve problems such as difficult to accurately distinguish, low sorting levels, and single types of sorted fruits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

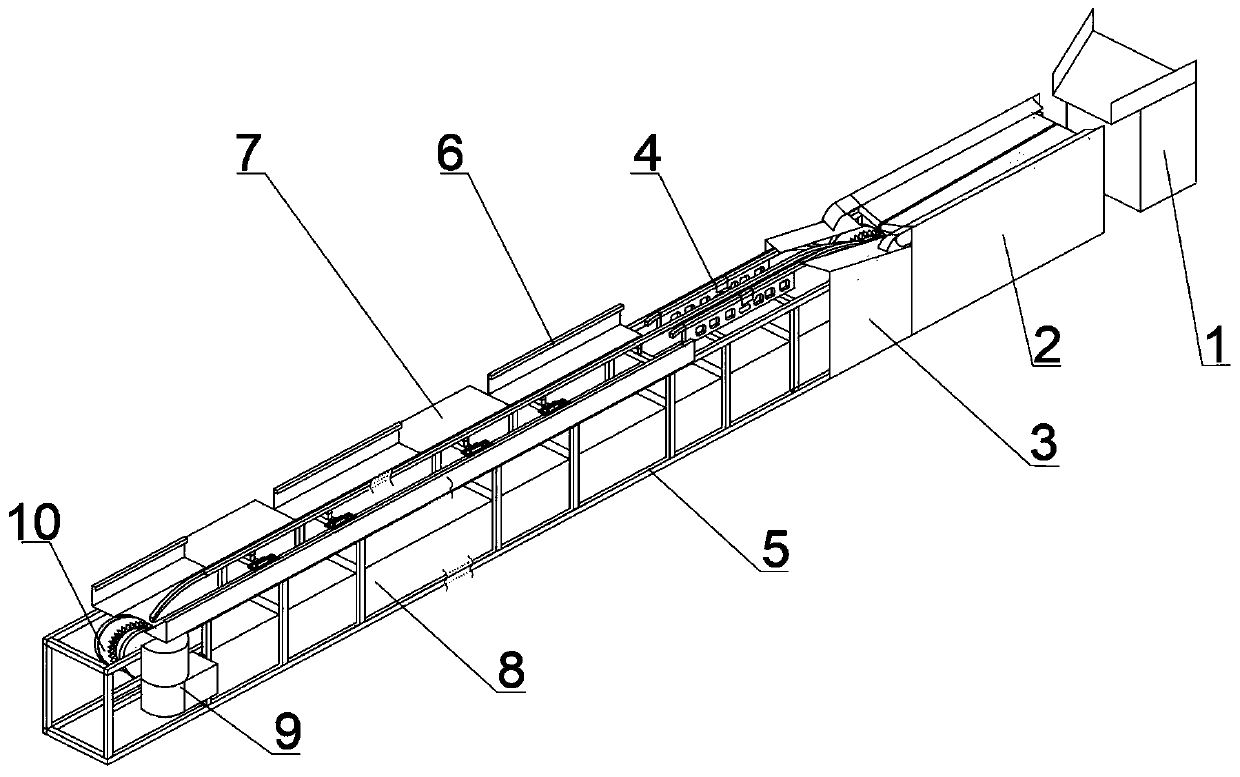

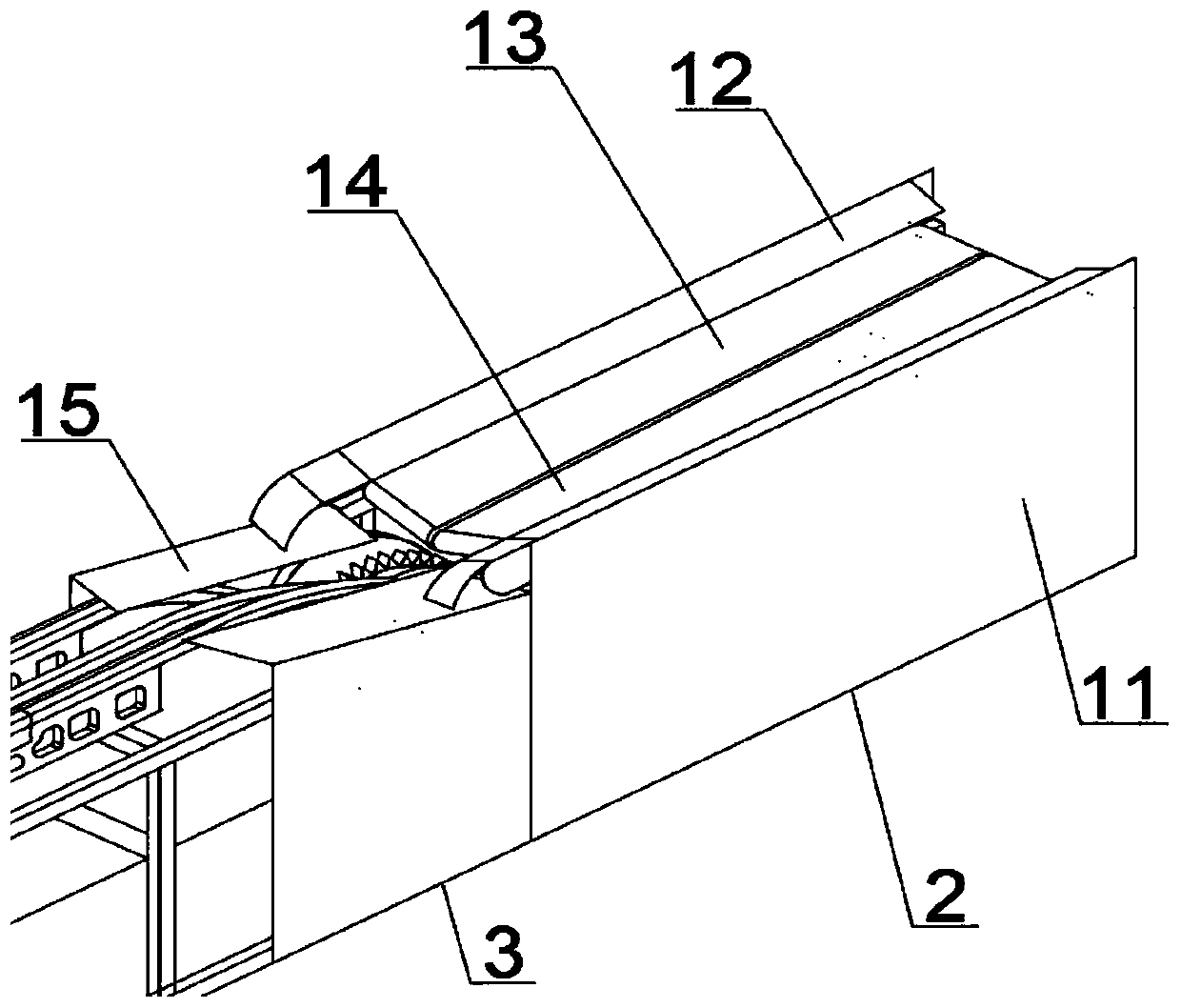

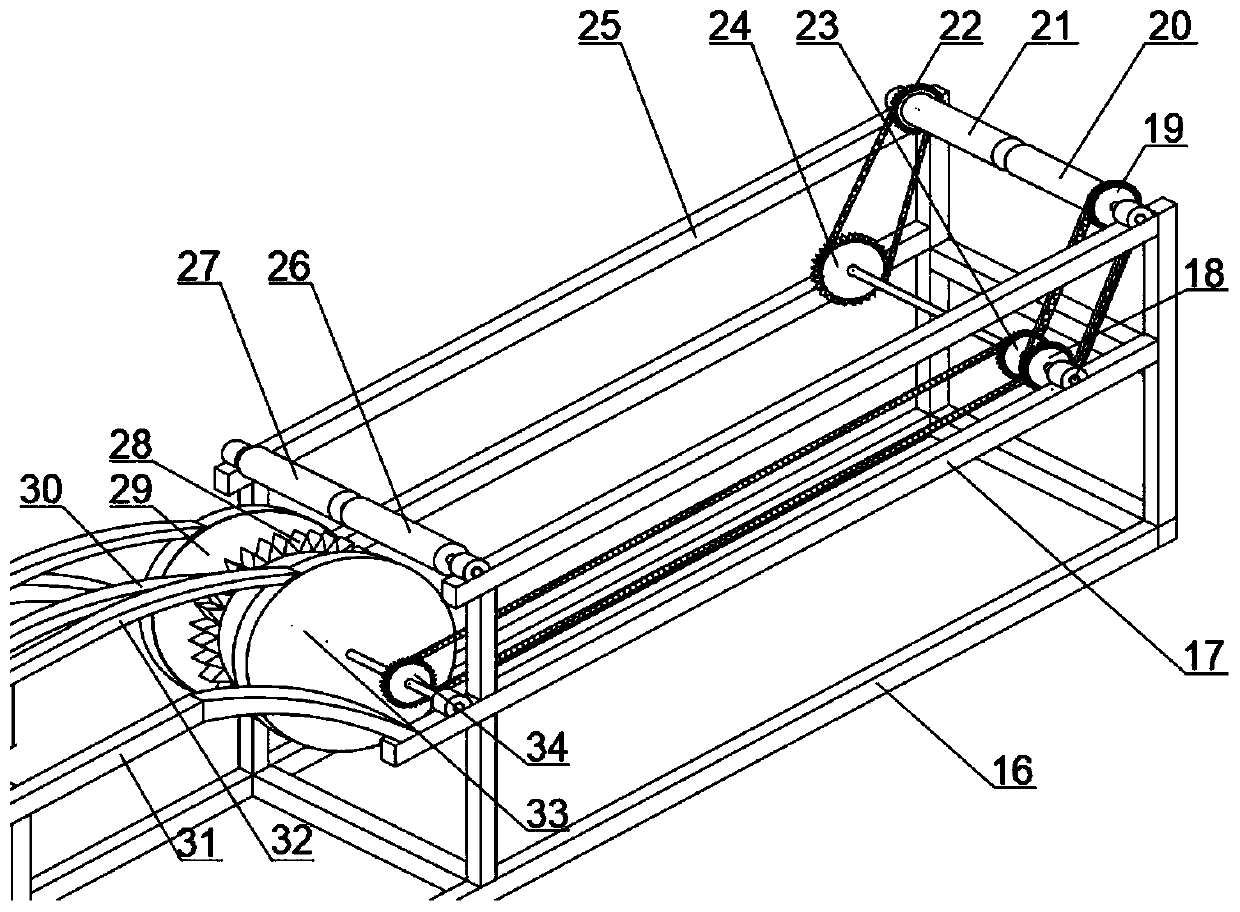

[0058]The fully automatic weighing type fruit sorting device involved in this embodiment has a main structure including a fruit delivery platform 1, an orderly delivery platform 2, a transmission part 3, a weighing platform 4, a sorting platform 5, a fruit protection shell 6, a sorting Picking mouth 7, belt conveyor box 8, motor 9, main rotating wheel 10, conveyor table shell 11, elastic shell 12, right conveyor belt 13, left conveyor belt 14, transmission part shell 15, transmission frame 16, middle support frame 17, left drive Wheel 18, left pulley 19, left drive shaft 20, right drive shaft 21, right pulley 22, rear drive wheel 23, right drive pulley 24, upper support frame 25, left transmission belt shaft 26, right transmission belt shaft 27, Main drive wheel 28, right rear leveling wheel 29, conveying rail 30, sorting rack 31, steady fruit rack 32, left rear leveling wheel 33, front drive wheel 34, fruit scale 35, fixed plate 36, rail bar 37, support Rail column 38, device...

Embodiment 2

[0069]A kind of fruit sorting control system based on the console 80 involved in this embodiment is used in conjunction with a fully automatic weighing fruit sorting device, and its main structure is divided into an interval setting module, a weight acquisition module, and a weight positioning module according to functions , weight classification module, weight processing module, speed acquisition module, popper control module and report generation module; the interval setting module is used to set the threshold range of multi-level weight intervals and each weight interval, and the interval setting module will The set interval parameters are transmitted to the weight classification module and the weight processing module, and the output terminals of the interval setting module are respectively connected with the receiving end of the weight classification module and the receiving end of the weight processing module; the weight classification module will obtain the weight signal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com