Residue clearing device used after opening and drilling device

A technology of removing device and drilling device, applied in the field of drilling processing, can solve the problem that the residue cannot be taken out

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

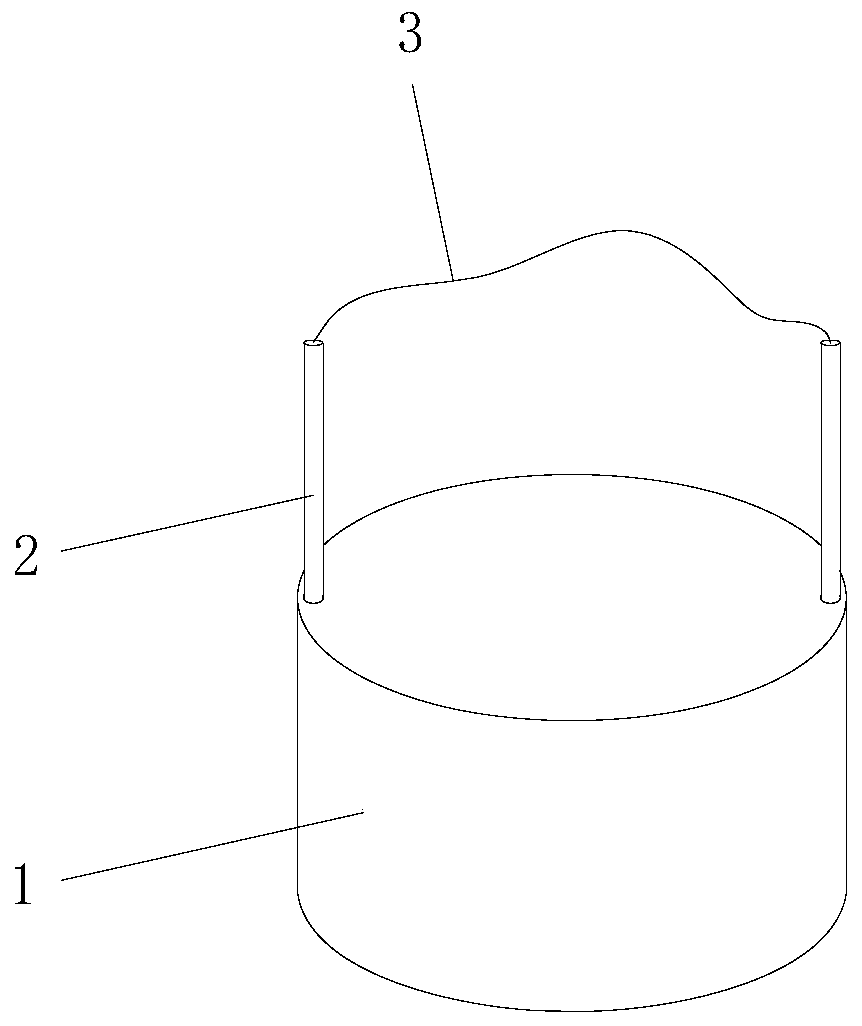

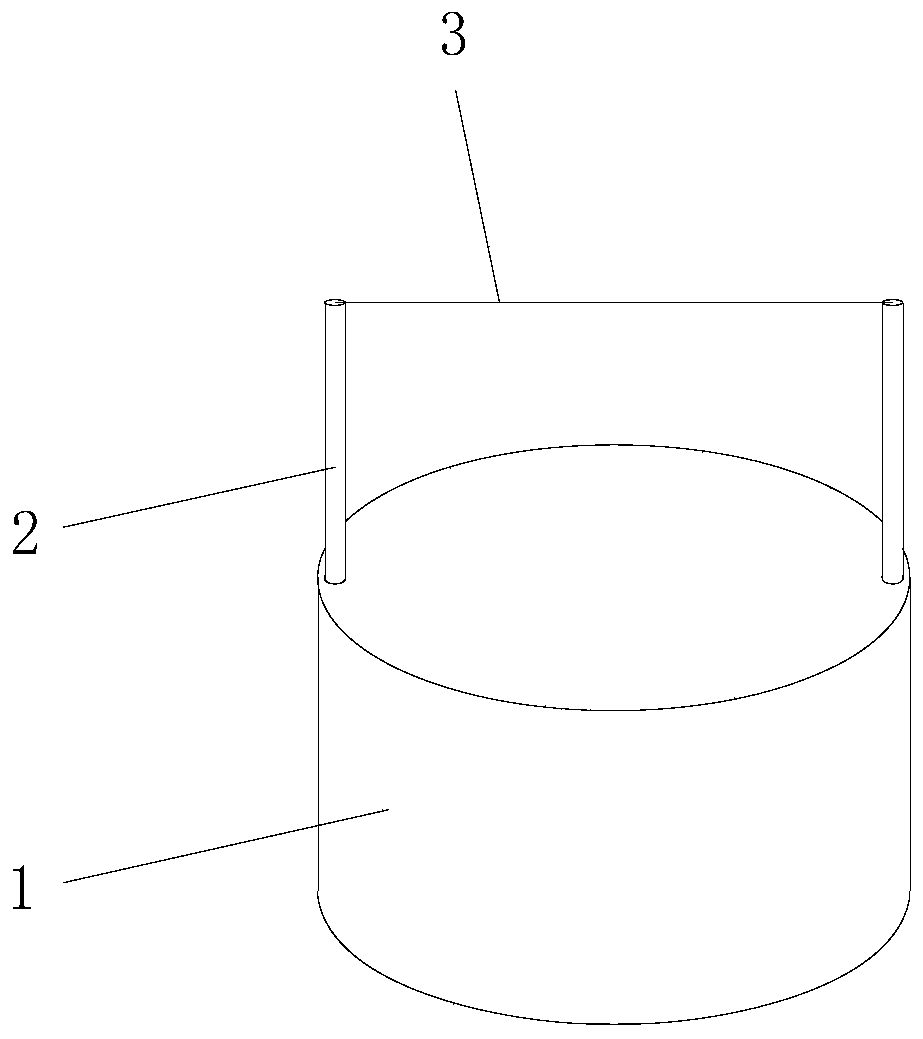

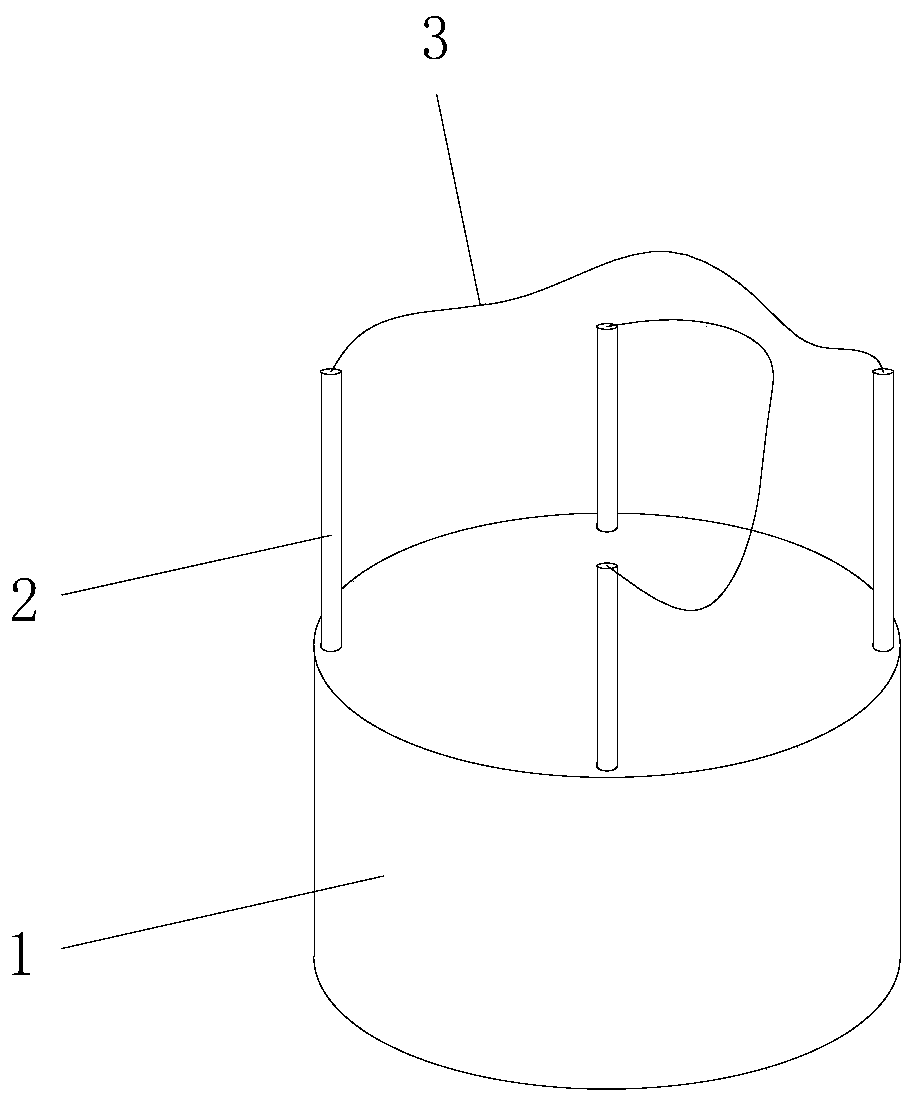

[0049] Such as figure 1 As shown, this embodiment provides a device for removing residues after opening a hole, which includes a base 1, a pipe body 2, a cutting line 3, and a driving mechanism installed in the base 1. The material of the tube body 2 is alloy steel, which has high hardness and strength. In this embodiment, the tube body 2 is provided with an even number, such as figure 1 with image 3 As shown, it can be two, four, six, etc., and the number of pairs of tube bodies 2 is set according to the hardness of the residue to increase the cutting speed and save processing time. This embodiment takes two as examples.

[0050] One end of the two pipes 2 is fixedly connected with one end surface of the base 1 and all the pipes 2 are distributed along the circumference of the base 1. In addition, the lengths of all tube bodies 2 extending from the base 1 are equal, and the angle formed between two opposite tube bodies 2 is 180°. The two ends of the cutting line 3 respectivel...

Embodiment 2

[0062] Such as Picture 8 As shown, this embodiment provides a drilling device, which includes a base 1, a pipe body 2, a cutting line 3, and a driving mechanism installed in the base 1. The serial numbers of the drawings in the second embodiment are the same as those in the first embodiment. One end of all the tube bodies 2 is fixedly connected to the center of one end surface of the base 1, and the end surface is provided with a through hole 18 communicating with the inner cavity of the base 1. The through hole 18 is far away from the tube body 2, and the distance between the through hole 18 and the tube body 2 is the maximum diameter of the opening. The two ends of the cutting line 3 respectively penetrate the base 1 from the pipe body 2 and the through hole 18 and are connected with the driving mechanism.

[0063] The specific structure of the driving mechanism is as follows:

[0064] Such as Picture 11 As shown, the driving mechanism includes a rack 5, a torque sensor 6, a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com