Chair back automatic drilling device

A punching device and chair back technology, applied to manipulators, fixed drilling machines, wood processing equipment, etc., can solve problems such as rework, installation is not easy to fasten, workers' physical hazards, etc., to achieve accurate positioning of incoming and outgoing materials , improve the overall processing efficiency, ensure the effect of quality and precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

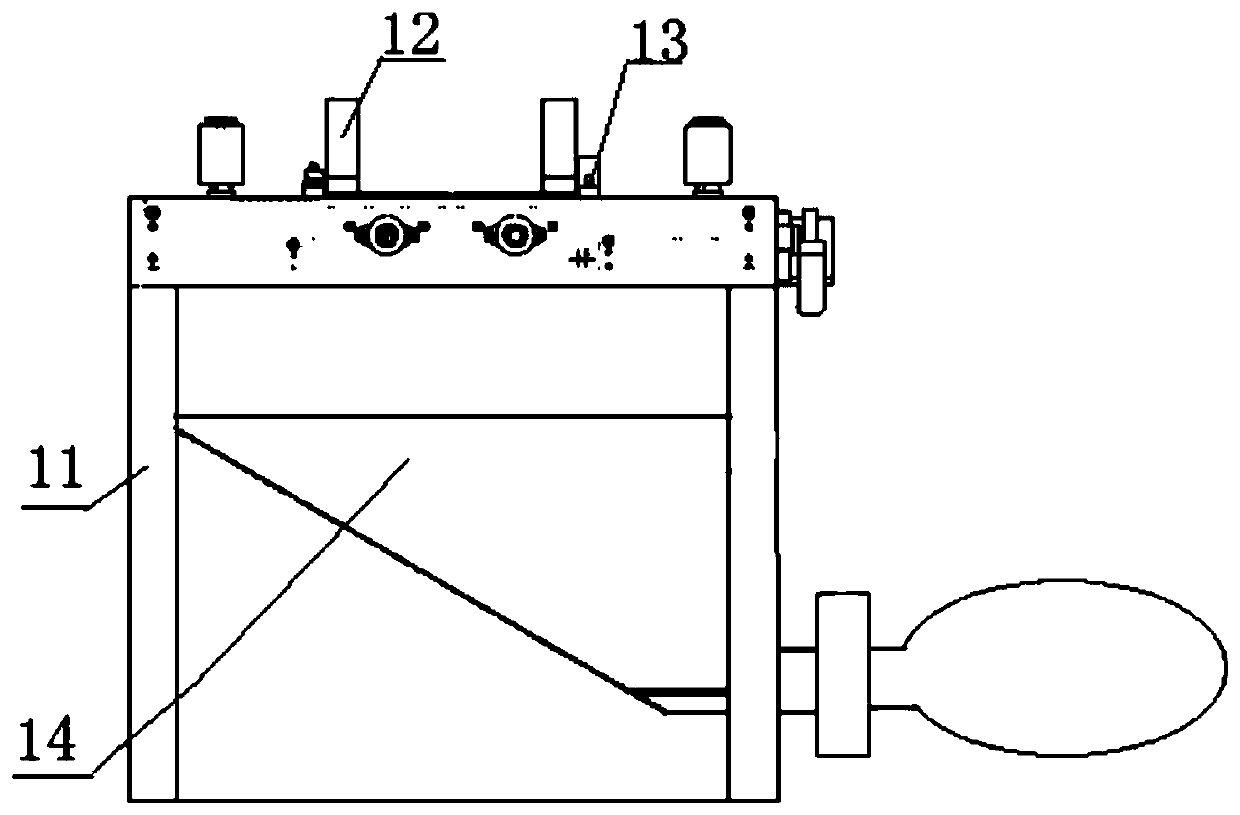

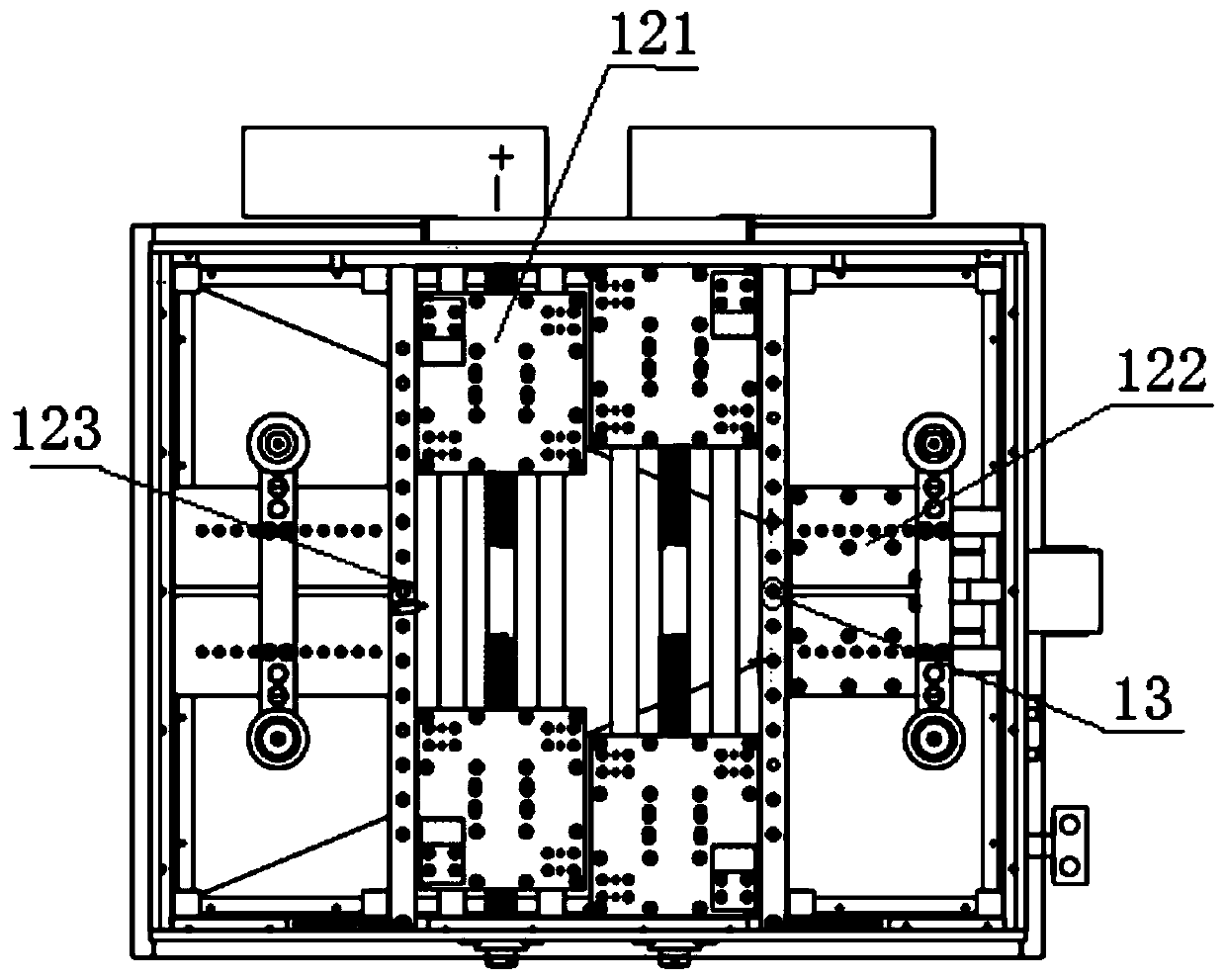

[0025] Such as Figure 1-Figure 5 As shown, the present invention schematically shows an automatic punching device for a chair back.

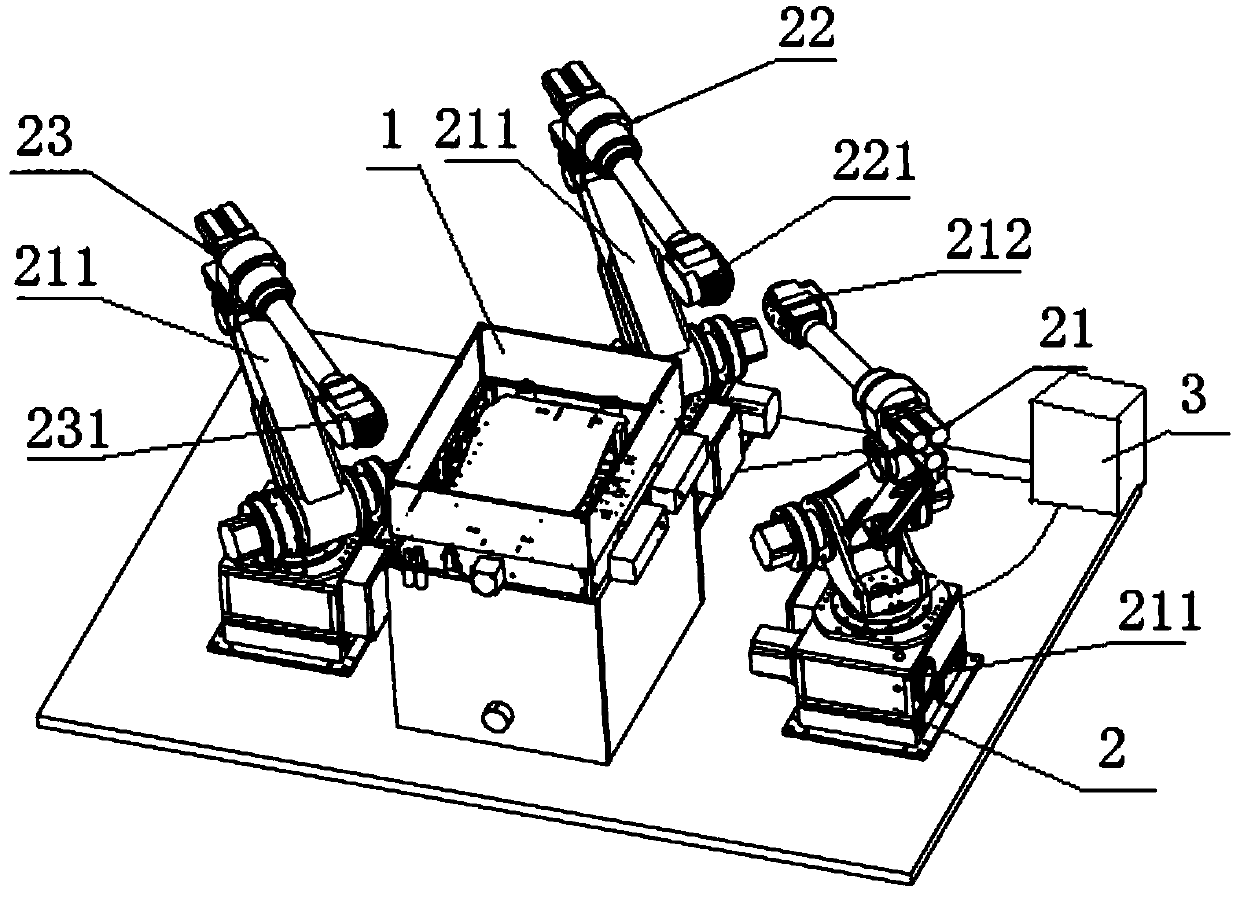

[0026] The invention discloses an automatic punching device for the back of a chair, such as figure 1 As shown, it includes a drilling platform 1, an auxiliary device 2 and a control device 3. The auxiliary device 2 is arranged around the drilling platform 1, and the control device 3 is located next to the auxiliary device 2 and the drilling platform 1. The auxiliary device 2 and the drilling platform 1 It is electrically connected with the control device 3, the punching platform 1 is used for clamping and fixing the back of the chair, the auxiliary device 2 ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap