Automatic labeling machine with self-inspection function

A labeling machine and labeling disc technology, which is applied in labeling machines, labels, packaging, etc., can solve the problems of unlabeled raw materials, unsuitable height of raw materials, and affecting the quality of labeling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

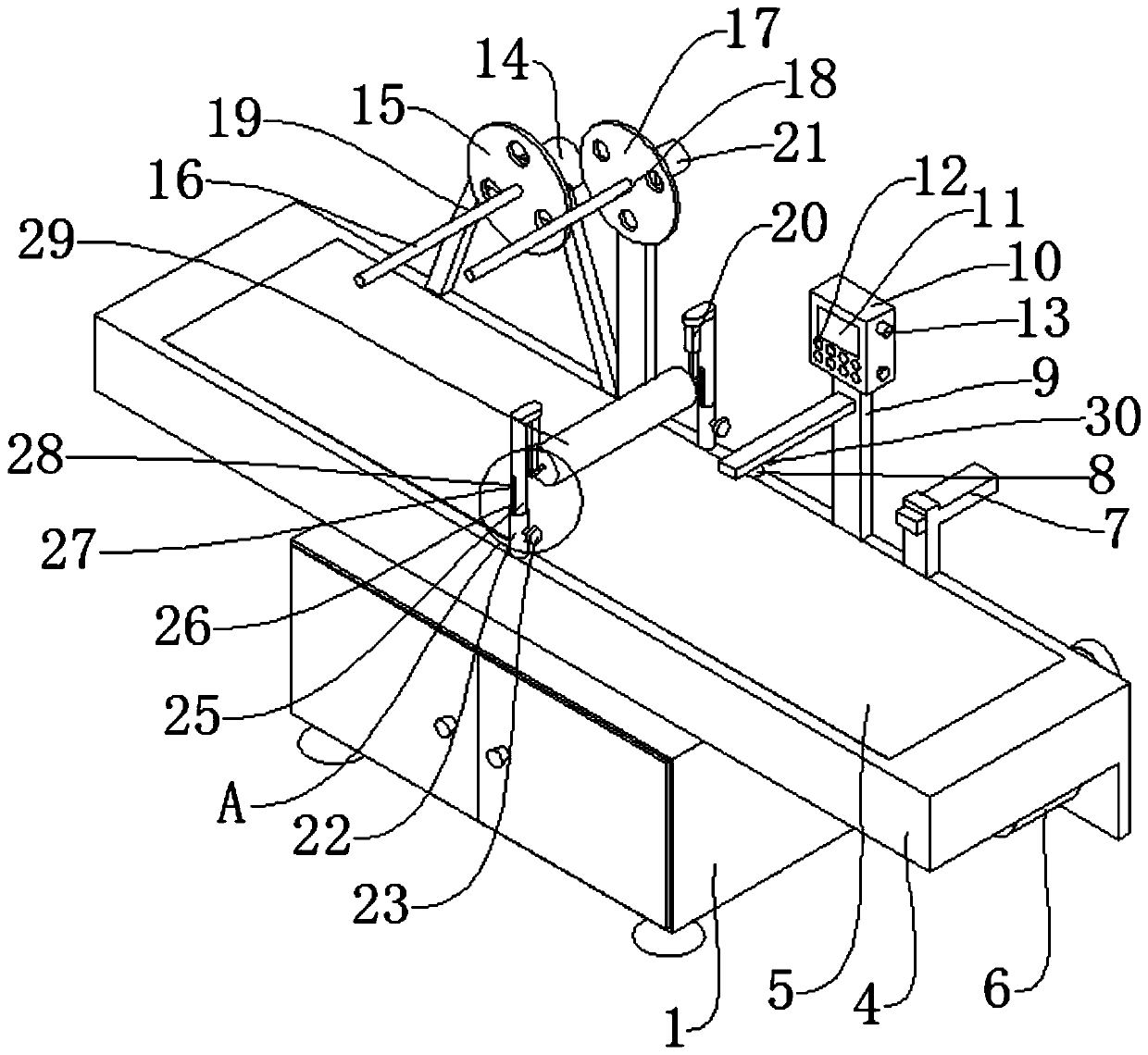

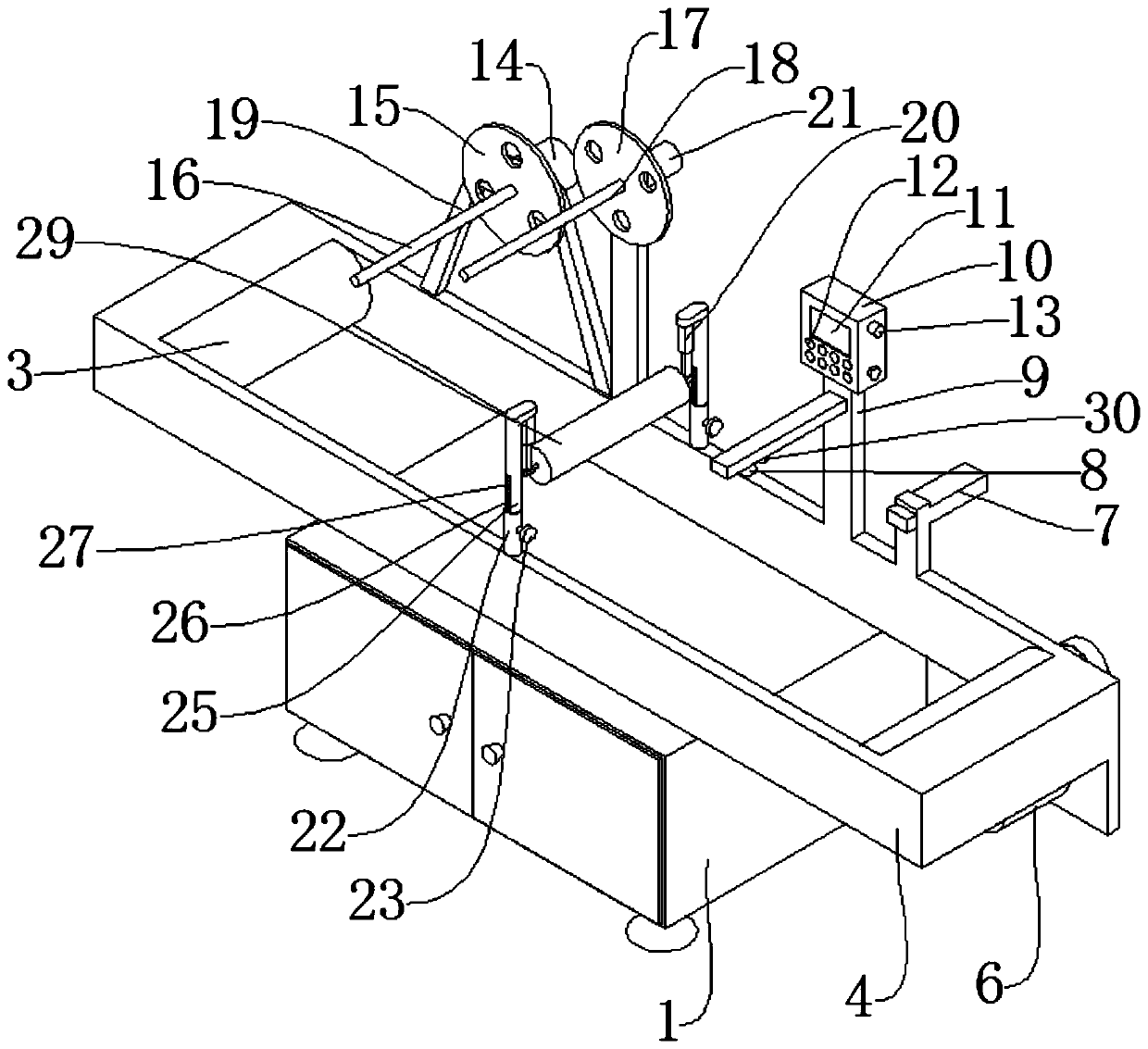

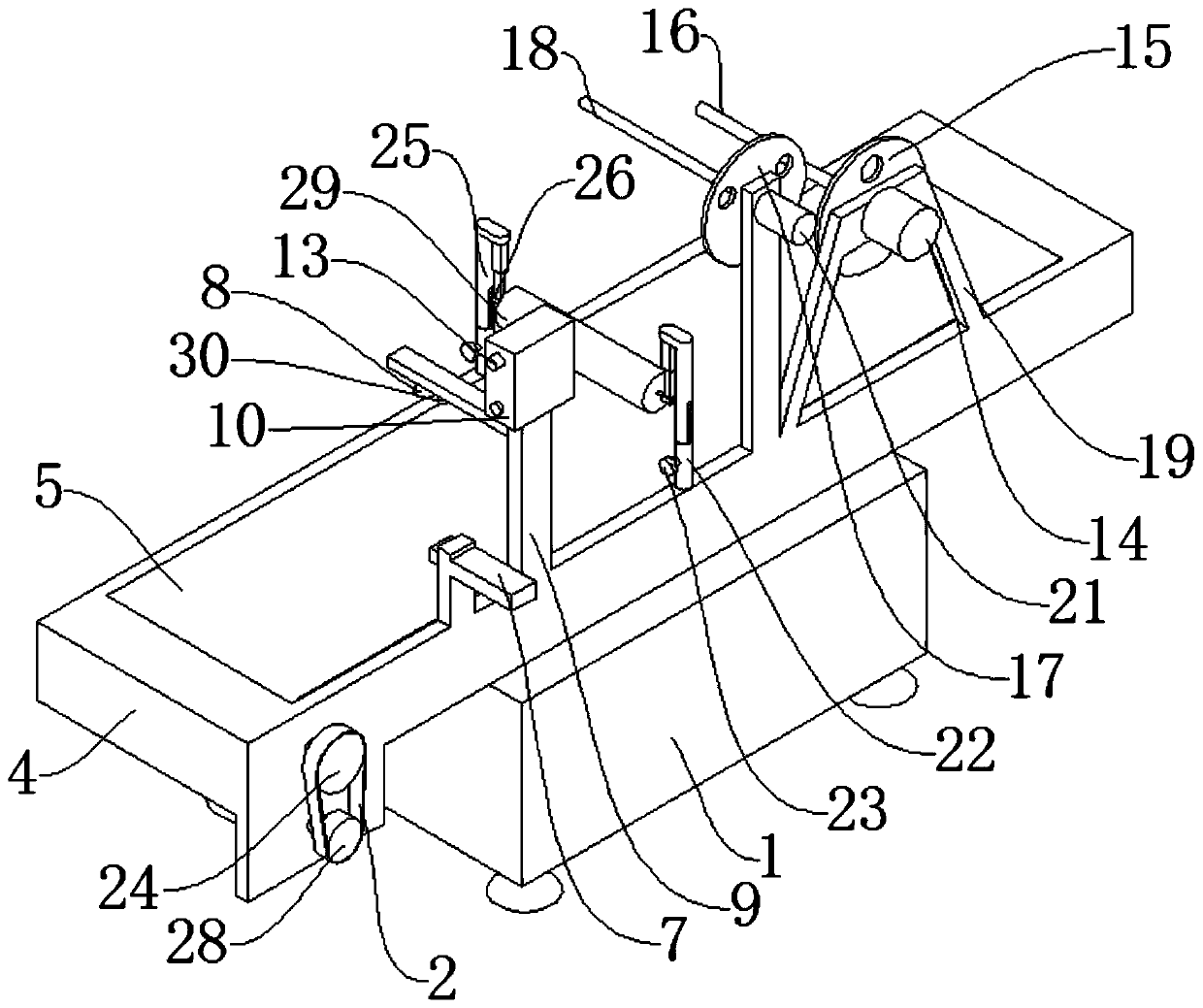

[0038] see Figure 1-Figure 6, the present invention provides a technical solution: an automatic labeling machine with self-inspection, including a bracket 1, a transport frame 4, a control chip 10, a recovery tray 15, and a finale 29. A transport frame 4 is arranged above the support 1, and the transport frame 4 The inner side is provided with a roller shaft 3, the roller shaft 3 is used to drive the conveyor belt 5 to rotate, the rear part of the roller shaft 3 is provided with a driven wheel 24, the driven wheel 24 is provided with a driving wheel 28 below, and a driving wheel 28 is arranged between the driving wheel 28 and the driven wheel 24. There is a belt 2, and the belt 2 is used to transmit the rotation of the driving wheel 28 so as to drive the driven wheel 24 to rotate. The front part of the driving wheel 28 is provided with a first motor 6, a conveyor belt 5 is provided between the roller shafts 3, and a conveyor belt 5 is provided above the conveyor frame 4. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com