Method for detecting breakage of road surface manhole cover

A manhole cover and damage technology, which is used in the field of detecting the damage of road manhole covers, can solve the problems of small damage area of manhole covers, unavoidable safety hazards, and reduced strength of manhole covers, so as to achieve timely detection and evaluation, facilitate priority treatment, and have a wide range of applications. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

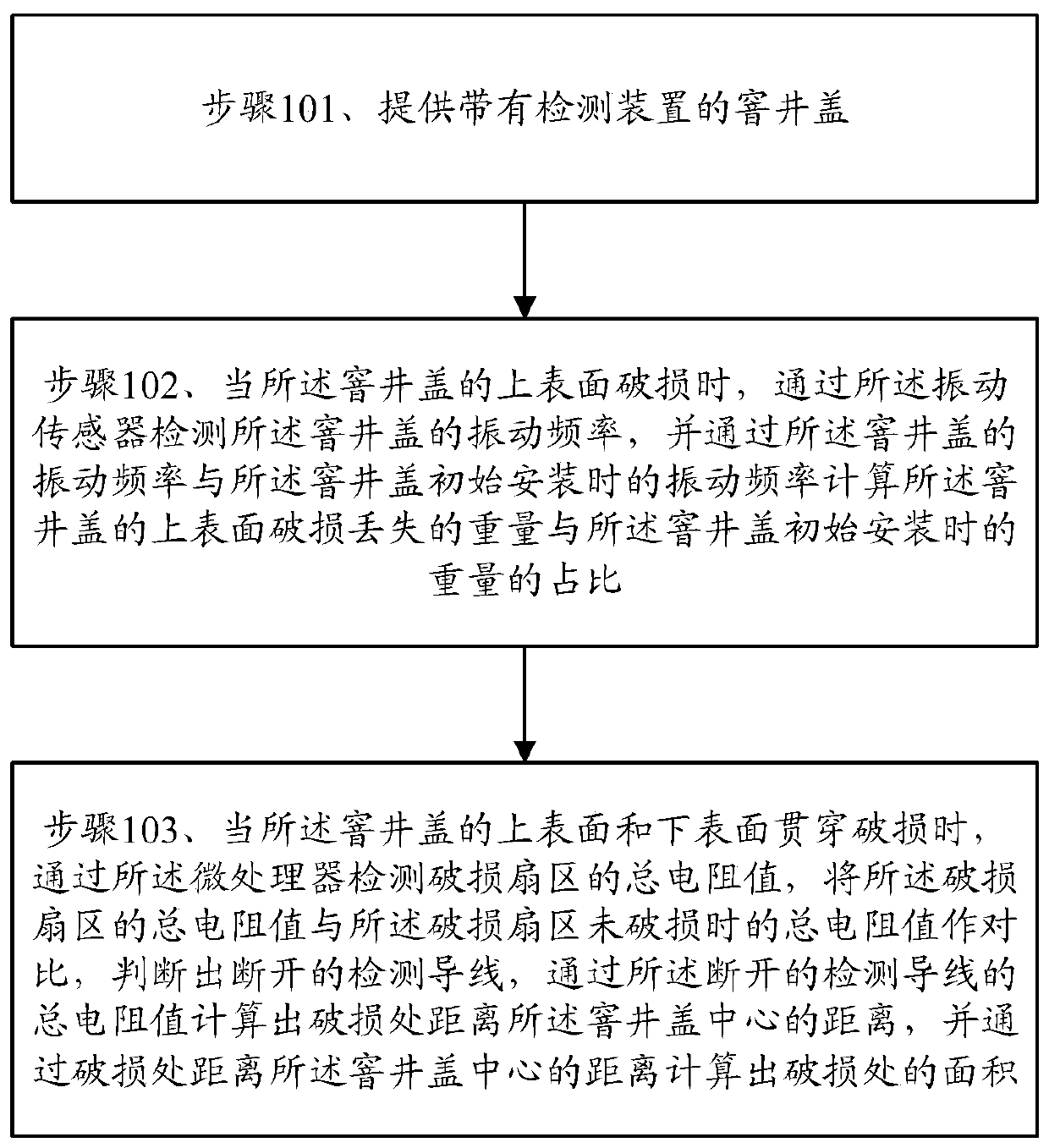

[0048] see figure 1 Shown is a specific embodiment of the method for detecting damage to the road surface manhole cover described in the present application, and the method includes steps:

[0049] Step 101, providing a manhole cover with a detection device, wherein,

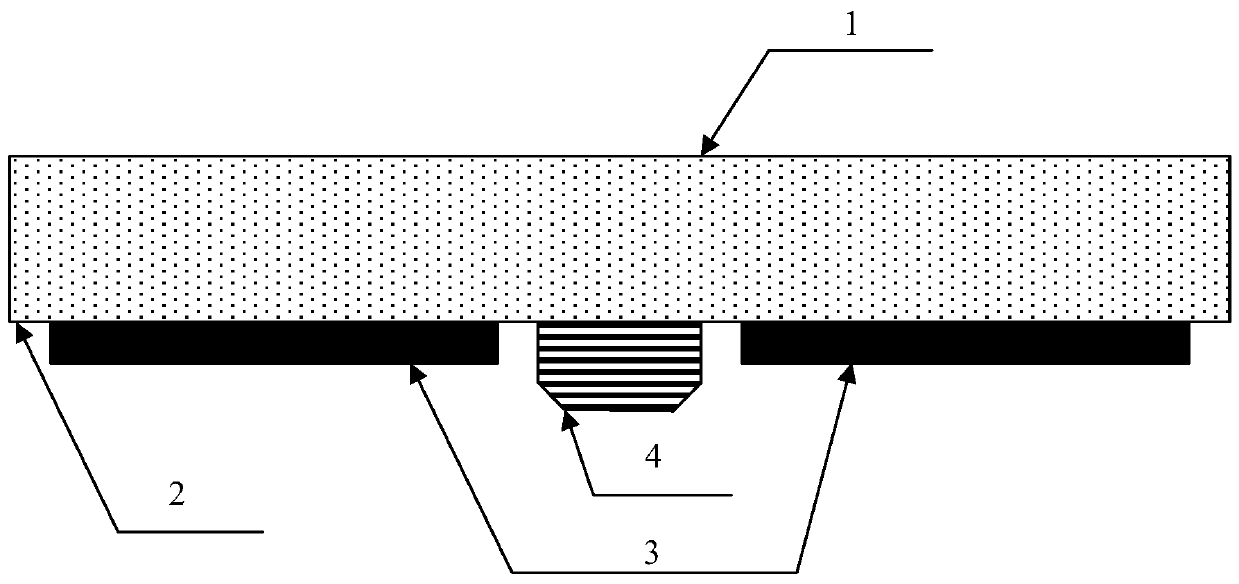

[0050]The manhole cover includes an upper surface 1 and a lower surface 2, the side of the manhole cover close to the road is the upper surface 1, and the side of the manhole cover away from the road is the lower surface 2; the detection device is located on the manhole cover The lower surface 2 includes a sector detection circuit 3 and a detection terminal 4, see figure 2 As shown; the detection terminal 4 is located in the middle of the lower surface 2 of the inspection shaft cover, including a battery, a microprocessor, and a vibration sensor; the sector is located on the lower surface 2 of the inspection shaft cover, surrounding the detection terminal 4 Arranged in equal parts, the number of sectors N 1 ...

Embodiment 2

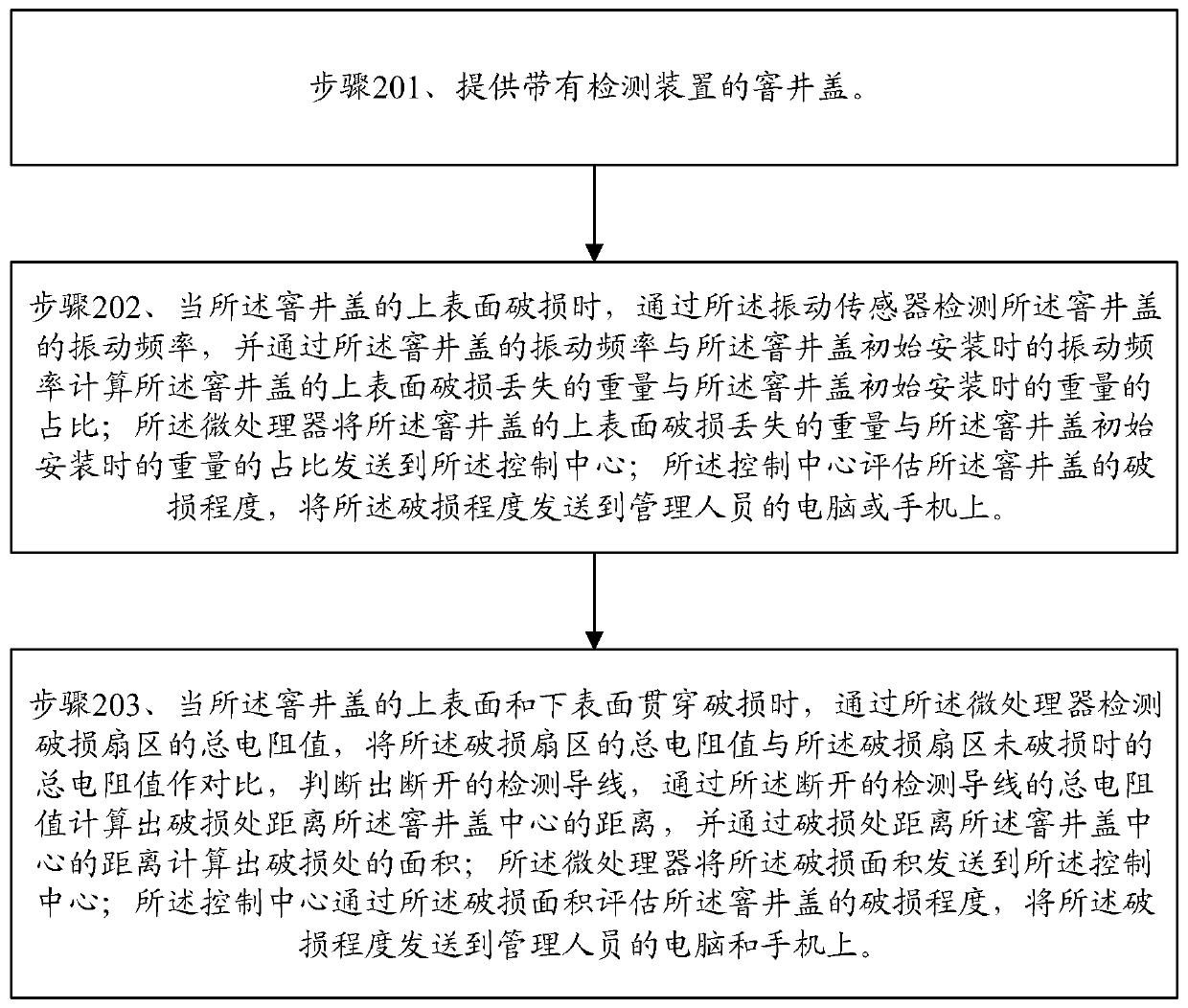

[0065] see image 3 Shown is another embodiment of the method for detecting damage to the road surface manhole cover provided by the present application, the method includes the steps of:

[0066] Step 201, providing a manhole cover with a detection device, wherein,

[0067] The manhole cover includes an upper surface and a lower surface, the side of the manhole cover close to the road is the upper surface, and the side of the manhole cover away from the road is the lower surface; the detection device is located on the lower surface of the manhole cover, It includes a sector detection circuit and a detection terminal; the detection terminal is located in the middle of the lower surface of the inspection shaft cover, including a battery, a microprocessor, and a vibration sensor; the sector is located on the lower surface of the inspection shaft cover, surrounding the The detection terminals are arranged in equal divisions, and the number of sectors N 1 ≥2; each sector include...

Embodiment 3

[0086] The present application provides a practical embodiment of a method for detecting damage to a pavement manhole cover. The method includes steps:

[0087] The purpose of this embodiment is to use a new manhole cover damage detection circuit and manhole cover damage assessment method to accurately locate the damaged position of the manhole cover, accurately estimate the damaged area of the manhole cover, and detect the manhole cover under the condition that the lower surface is not damaged. Damage to the upper surface of the manhole cover.

[0088]The purpose of this embodiment is achieved through the following scheme: a manhole cover damage detection network composed of a multi-sector detection circuit is used to calculate and accurately locate the area where the manhole cover is damaged and the position of the damaged point from the center of the manhole cover through the impedance of the circuit, so as to detect the manhole cover The damage degree of the manhole cove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com