Wall decoration structure and its construction method

A decorative structure and wall technology, applied in the field of architectural decoration, can solve the problems of unfavorable human health, long construction period, cumbersome process, etc., and achieve the effects of good quality control, fast and convenient installation, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

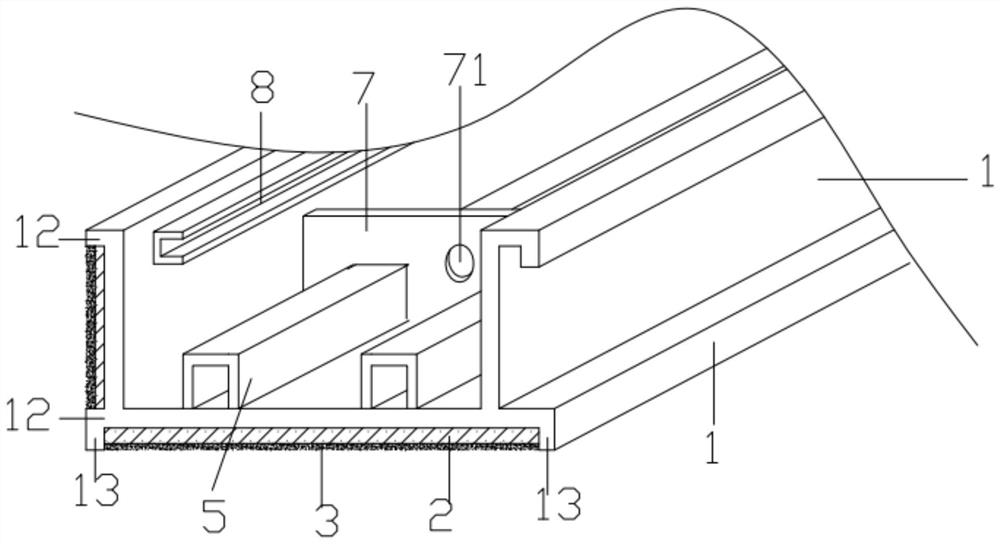

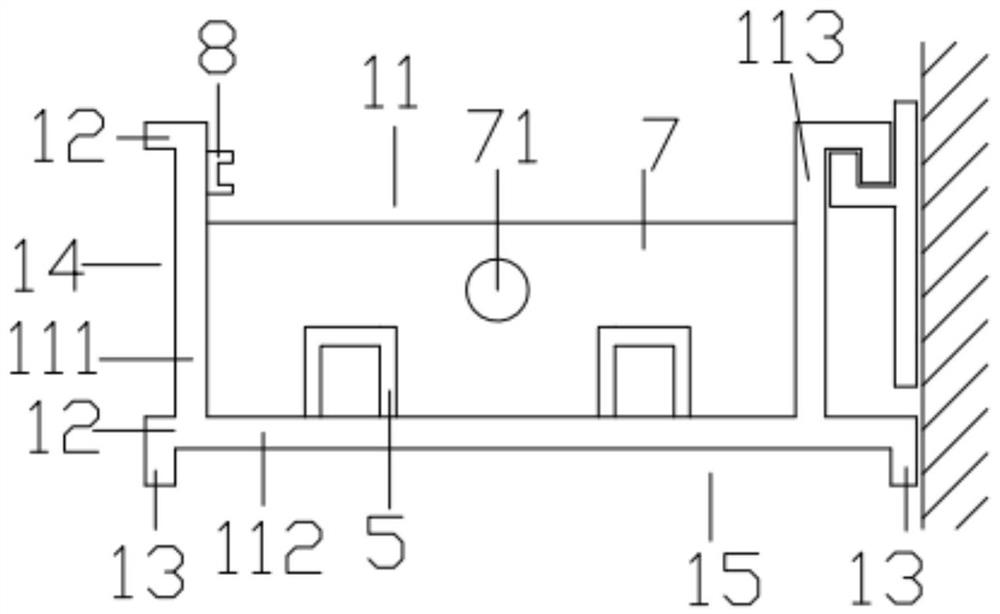

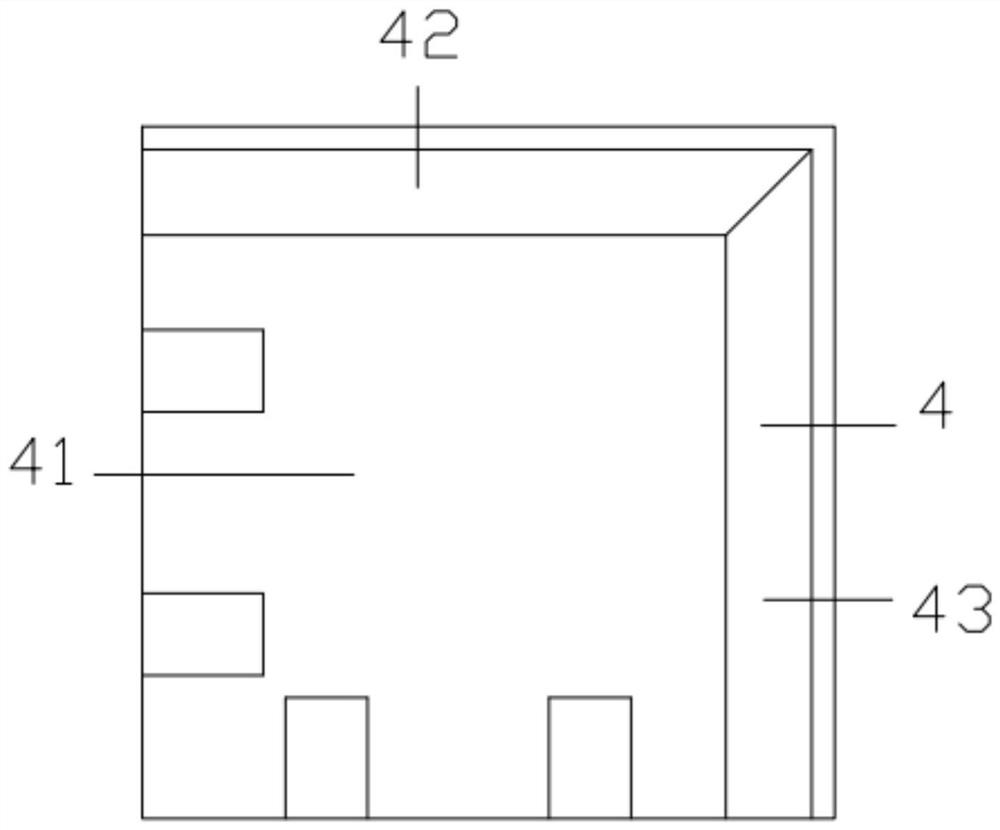

[0075] As an embodiment of the present invention, the ceiling frame body 1 can be uniformly installed in the factory with the light belt groove 8, the reinforcing rib 7 with the wire pipe through hole 71, and the light hole surrounded by the closed score line can be pressed. The cover plate 9 and the wall panel unit 6 can be uniformly installed in the factory with the reinforcing rib 7 having the wire pipe via hole 71, pressing the cover plate 9 surrounded by the closed score line, improving the integration degree of the wall decoration structure, and further Simplify the process, effectively shorten the construction time and reduce labor costs.

[0076] Further, a light strip groove 8 for accommodating an LED light strip is arranged in the groove cavity 11 , and the light strip groove 8 is arranged on the outer side plate 111 or the inner side plate 113 .

[0077] refer to Figure 1-Figure 2 As shown, as an embodiment of the present invention, the light belt groove 8 can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com