Air-tight door and sealing method for large-scale additive manufacturing

An additive manufacturing and sealing door technology, applied in the field of sealing doors, can solve the problems of inconvenient movement, manual push and pull, and time-consuming, so as to ensure the sealing effect and opening and closing efficiency, reduce wasted time, and improve opening and closing efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

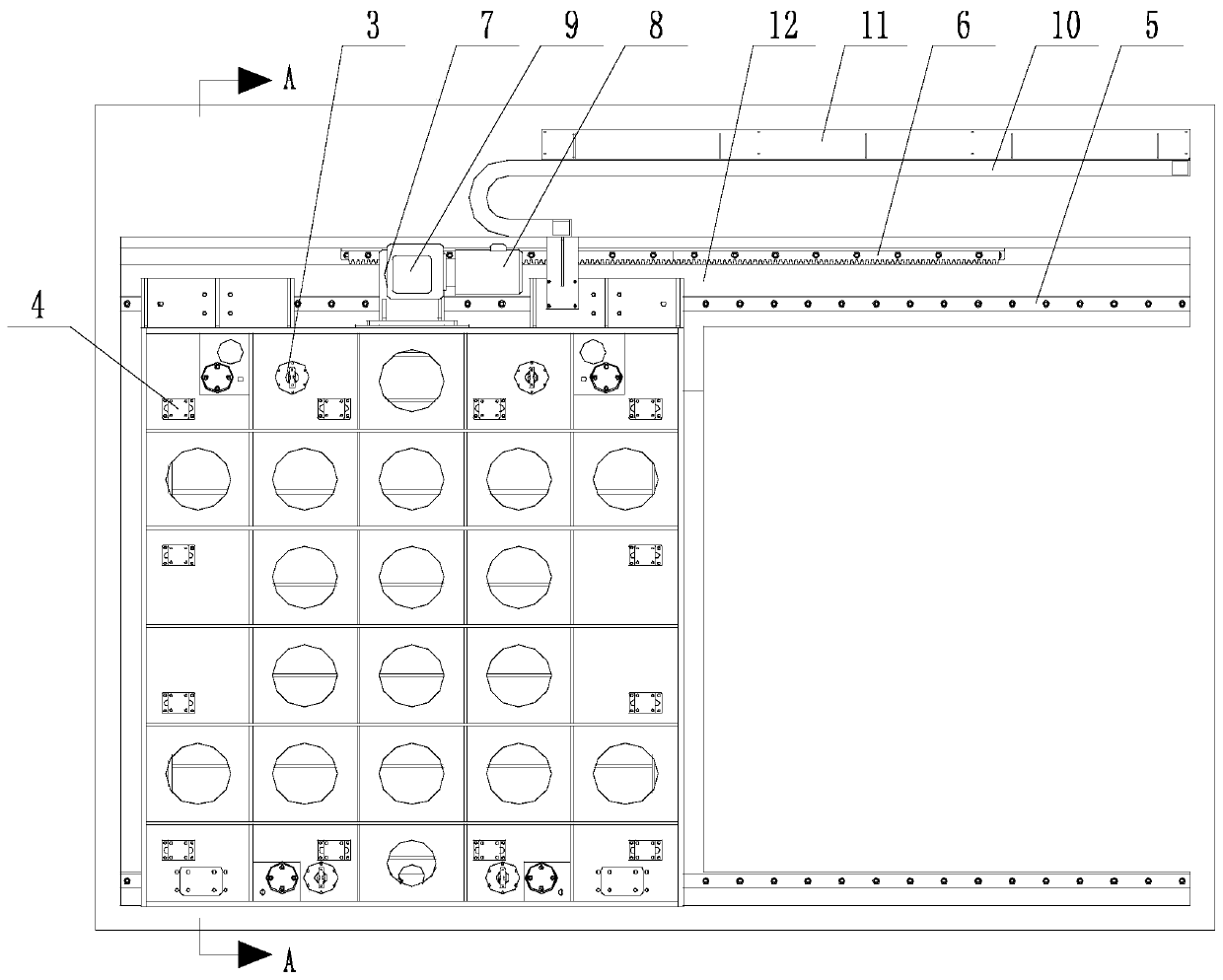

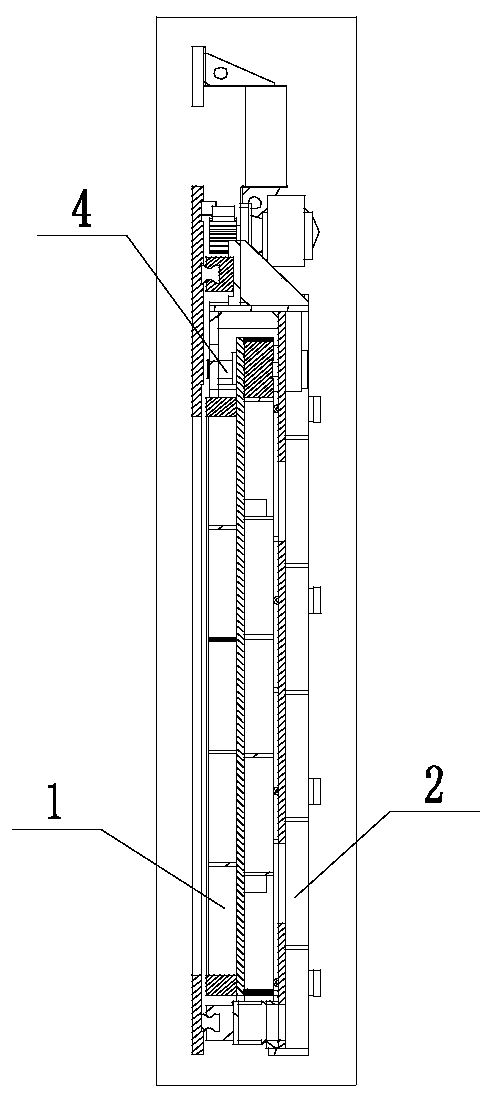

[0030] Such as figure 1 and figure 2 A hermetic door for large-scale additive manufacturing is shown, including an inner door 1 facing the additive manufacturing space, and an outer door 2 overlapping the outer side of the inner door 1, the outer door 2 and the inner door 1 They are connected by several tensioning mechanisms 3, and also include several tensioning mechanisms 4 located between the outer door 2 and the inner door 1, the said tensioning mechanisms 4 are used to push the inner door 1 towards the inner direction; the outer door 2 It can move along the linear guide rail 5, the linear guide rail 5 is horizontal, and the length direction of the linear guide rail 5 is perpendicular to the vertical line between the inner and outer 1 and the outer door 2, and also includes a function for driving the outer door 2 on the linear guide rail 5. Mobile drive mechanism.

[0031] A sealing method for large-scale additive manufacturing: the inner door 1 and the outer door 2 are o...

Embodiment 2

[0036] Such as figure 1 and figure 2 Shown is a hermetic door for large-scale additive manufacturing. On the basis of Embodiment 1, the drive mechanism includes a rack 6 parallel to the linear guide rail 5 and a gear meshed with the rack 6. 7. A power device for driving the gear 7 to rotate, and the power device is relatively fixed to the outer door 2 . The power device includes a motor 8 and a reducer 9 , the output shaft of the motor 8 is connected with the input end of the reducer 9 , and the output shaft of the reducer 9 is connected with the gear 7 . It also includes a drag chain 10 for installing the cables of the motor 8 . It also includes a drag chain installation plate 11 for installing the drag chain 10 . It also includes a main installation plate 12 for installing the linear guide rail 5 , and the main installation plate 12 is located above the outer door 2 . The rack 6 is also mounted on the main mounting plate 12 . The clamping mechanism 4 is an air cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com