Perforating and fracturing method with effect of increasing modification degree of tight oil horizontal well

A technology for horizontal wells and tight oil, which is applied in earthwork drilling, wellbore/well components, production fluids, etc. It can solve the problems of low probability of effective support, low single well production and design expectations, and achieve the goal of improving single well production and The degree of recovery, the improvement of plugging effect, and the effect of broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings.

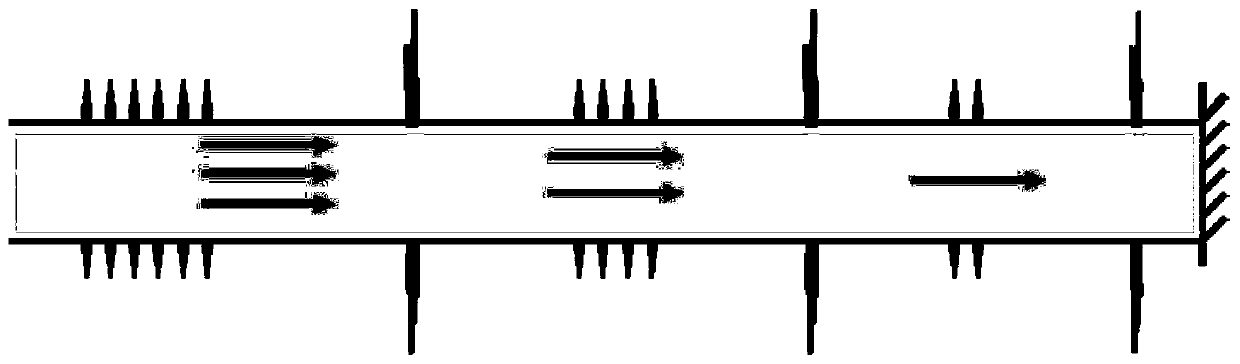

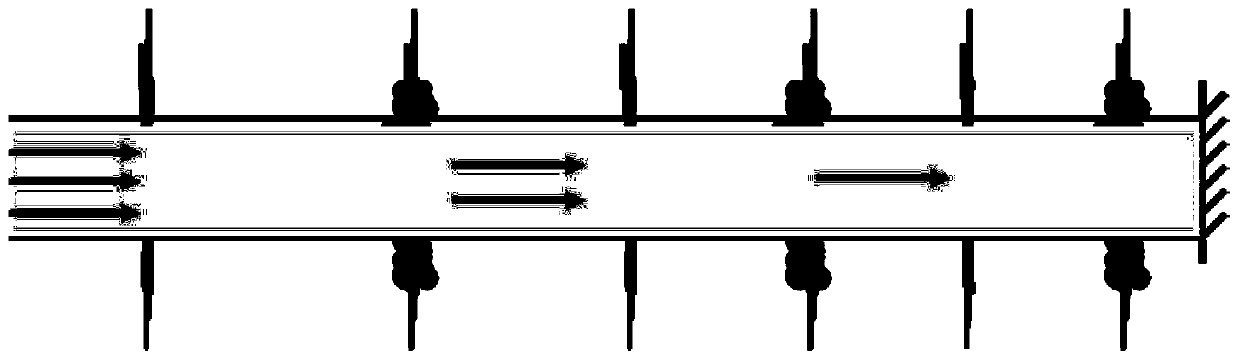

[0033] A differentiated perforation and dynamic multi-stage temporary plugging fracturing method for improving the stimulation degree of tight oil horizontal wells according to the present invention comprises the following steps:

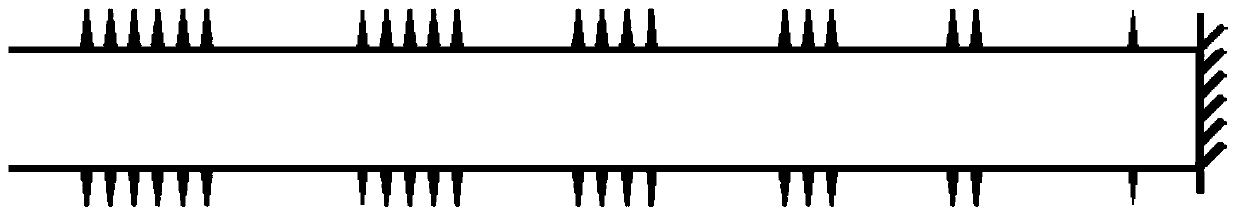

[0034] In step (1), the perforation position of each section is selected according to the interpretation results of reservoir logging, and each section has N clusters of perforation, and the minimum horizontal principal stress value of each cluster is calculated, and the length of each perforation section is optimized according to the minimum horizontal principal stress value and the number of perforation holes;

[0035] Among them, the calculation of the minimum horizontal principal stress adopts the formula (1):

[0036]

[0037] In the formula, σ h is the minimum horizontal stress, MPa; ν is Poisson’s ratio; α is Biot’s coefficient...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com