Starter

A technology of a starter and a starter claw, applied in the field of starters, can solve the problems of the influence of the stability of the starter and the starter cup, and the uneven force of the starter claw, so as to improve the coordination stability, uniform force and ensure stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

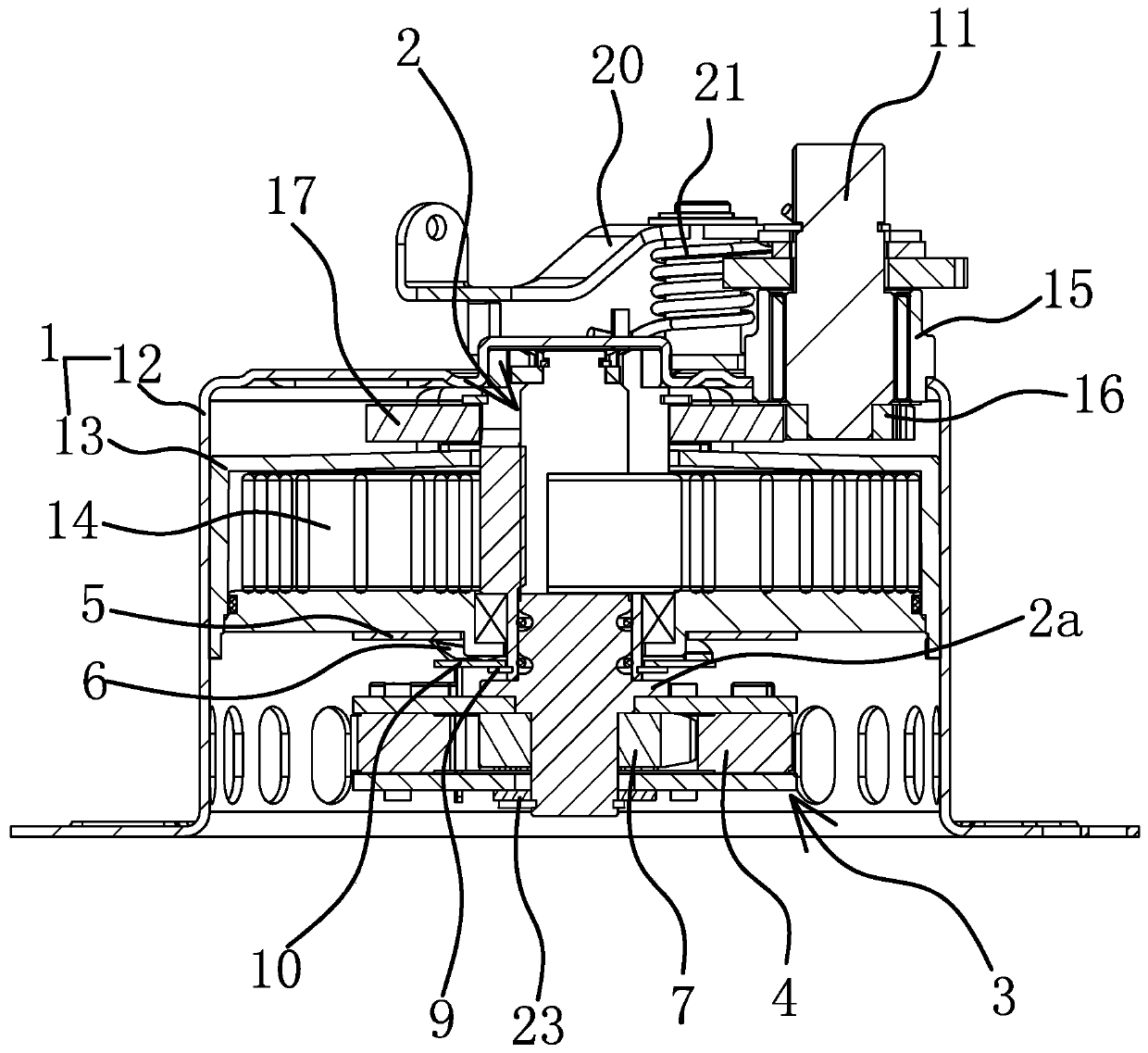

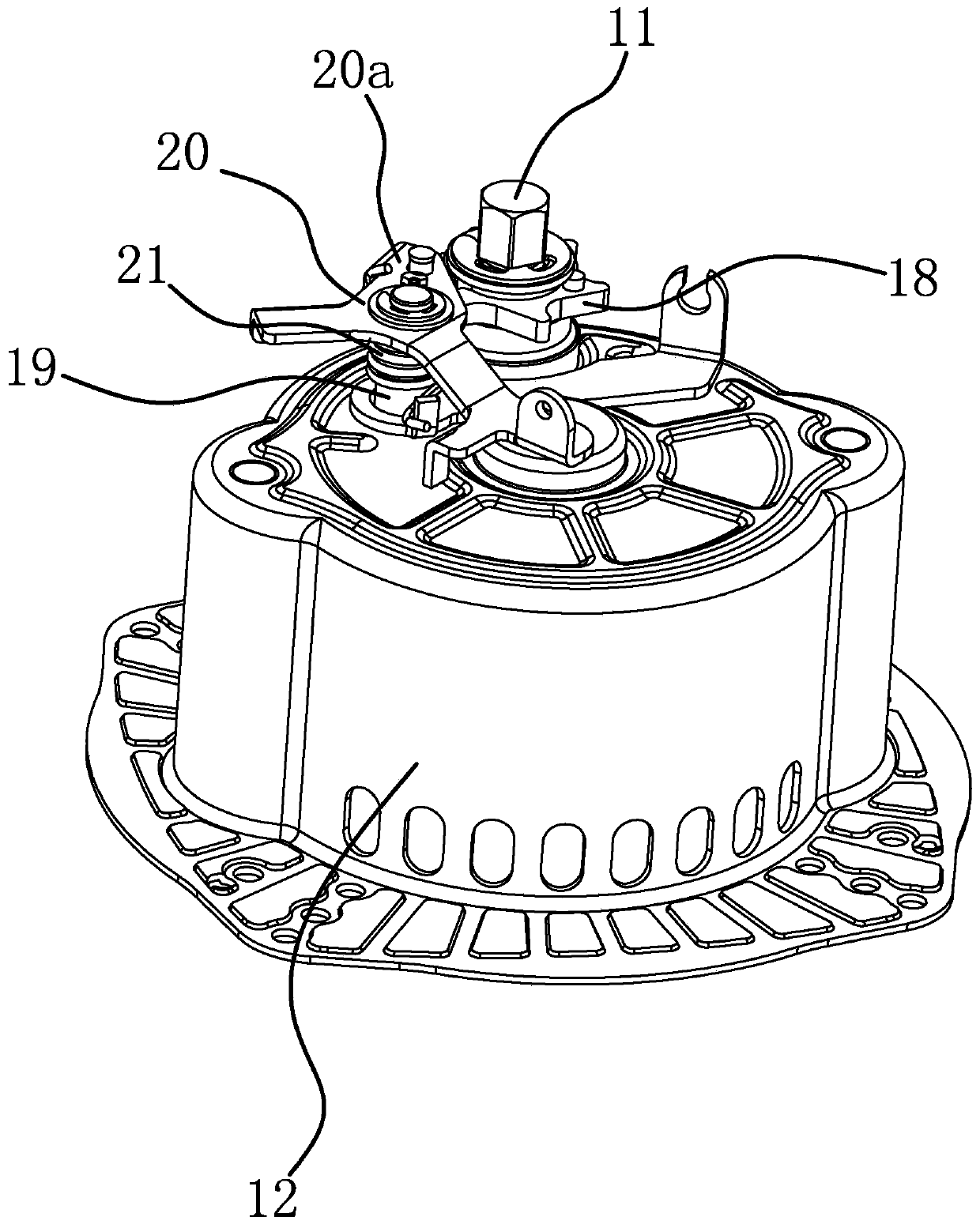

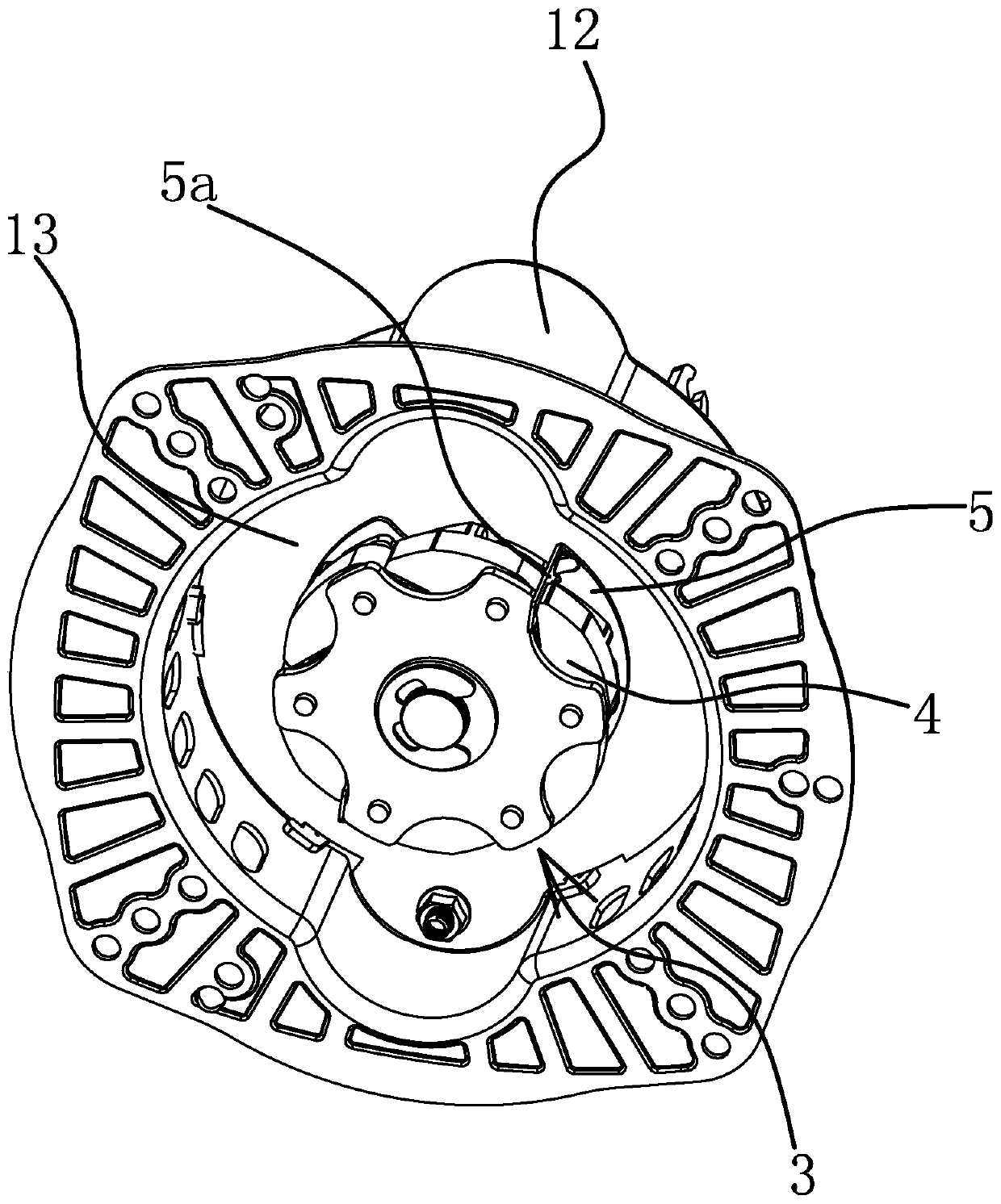

[0055] Such as figure 1 , figure 2 with image 3 As shown, a starter includes a body 1, a rotating shaft 2 disposed in the body 1 and capable of rotating, a starting shaft 11 disposed on the body 1 and capable of driving the rotating shaft 2 to rotate, and a clutch mechanism connected to the rotating shaft 2.

[0056] Such as figure 1 As shown, the body 1 includes a casing 12 with one end open and the other closed and a spring box 13 fixed in the casing 12. A scroll spring 14 is arranged in the spring box 13, and one end of the scroll spring 14 is fixed on the spring On the box 13 , the rotating shaft 2 passes through the center of the scroll spring 14 , and one end of the inner edge of the scroll spring 14 is connected to the rotating shaft 2 . A bearing seat 15 is fixed on the closed end surface of the casing 12. The starting shaft 11 is arranged in the bearing seat 15. One end of the starting shaft 11 extends into the casing 12 and is connected with a driving gear 16. O...

Embodiment 2

[0073] The structure and principle of this embodiment are basically the same as that of Embodiment 1, the difference is that in this embodiment, the elastic member 6 is a spring, one end of the spring leans against the blocking plate 10, and the other end of the spring leans against the friction plate 5 on.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com