Wiring device for magnetic suspension bearing, compressor and refrigeration equipment

A magnetic suspension bearing and wiring device technology, applied in mechanical equipment, bearings, shafts and bearings, etc., can solve the problems of difficult fixing, easy breakage and complexity of lead wires, so as to improve reliability, prolong the service life of lead wires, and simplify wiring and lead wires. The effect of the operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

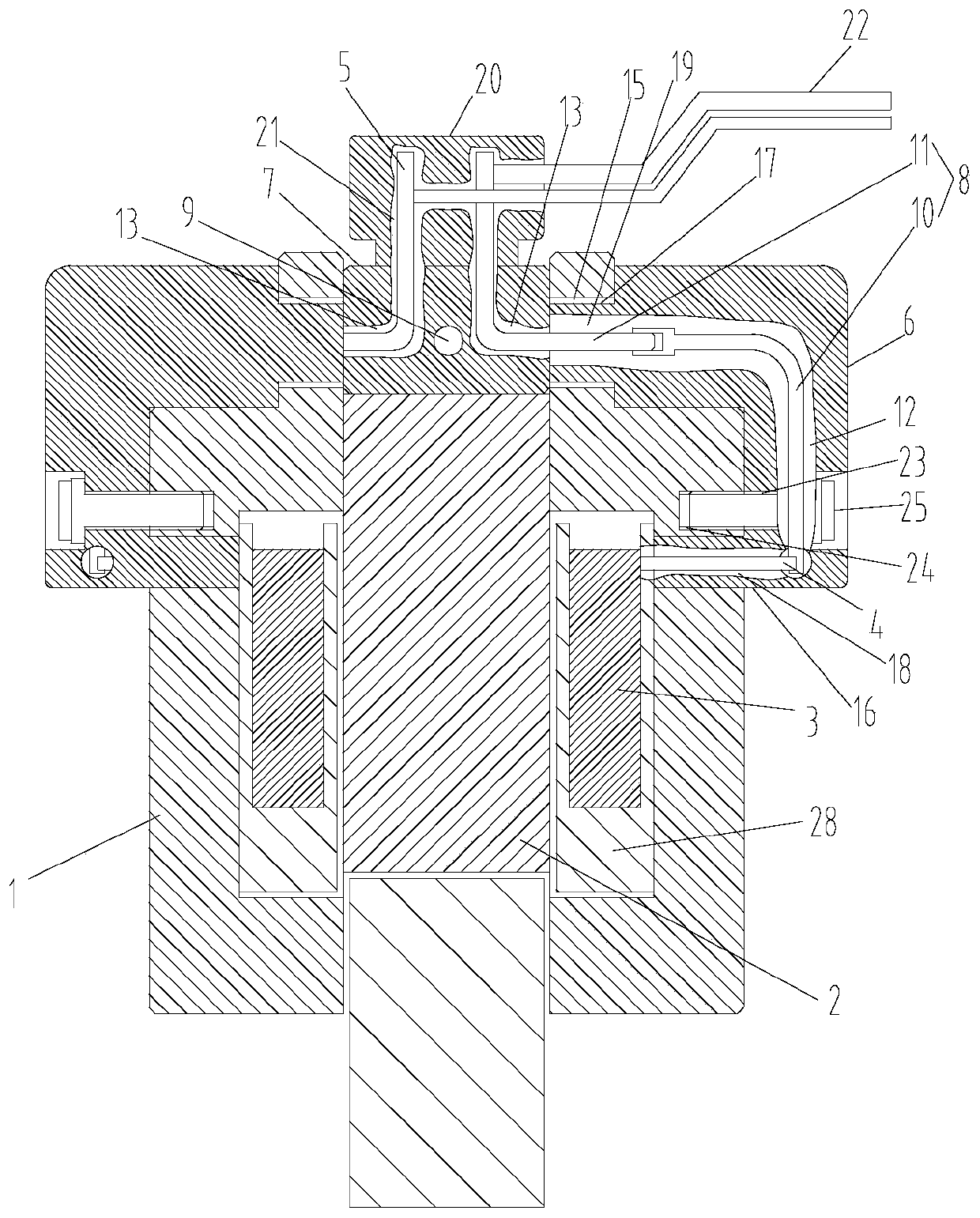

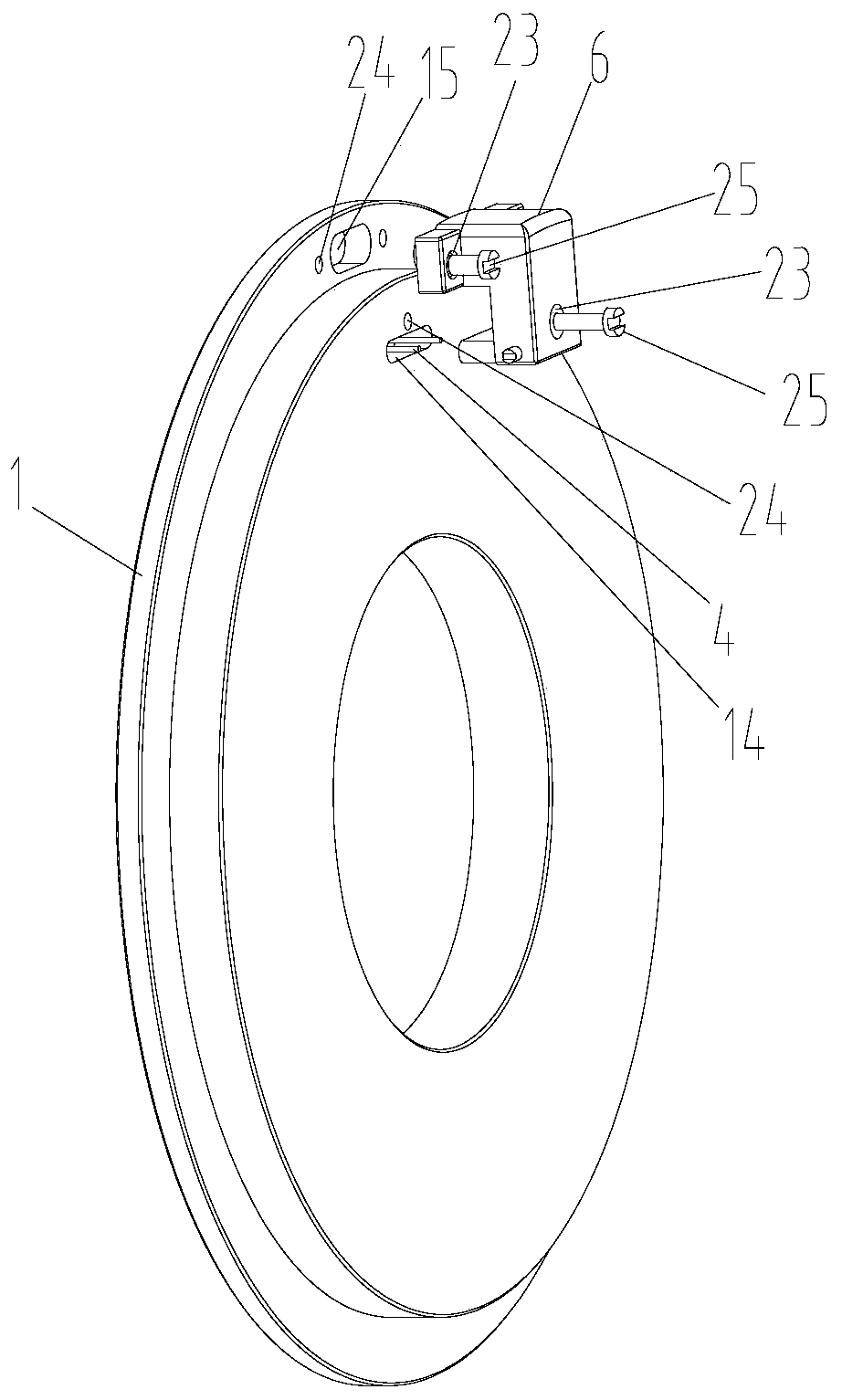

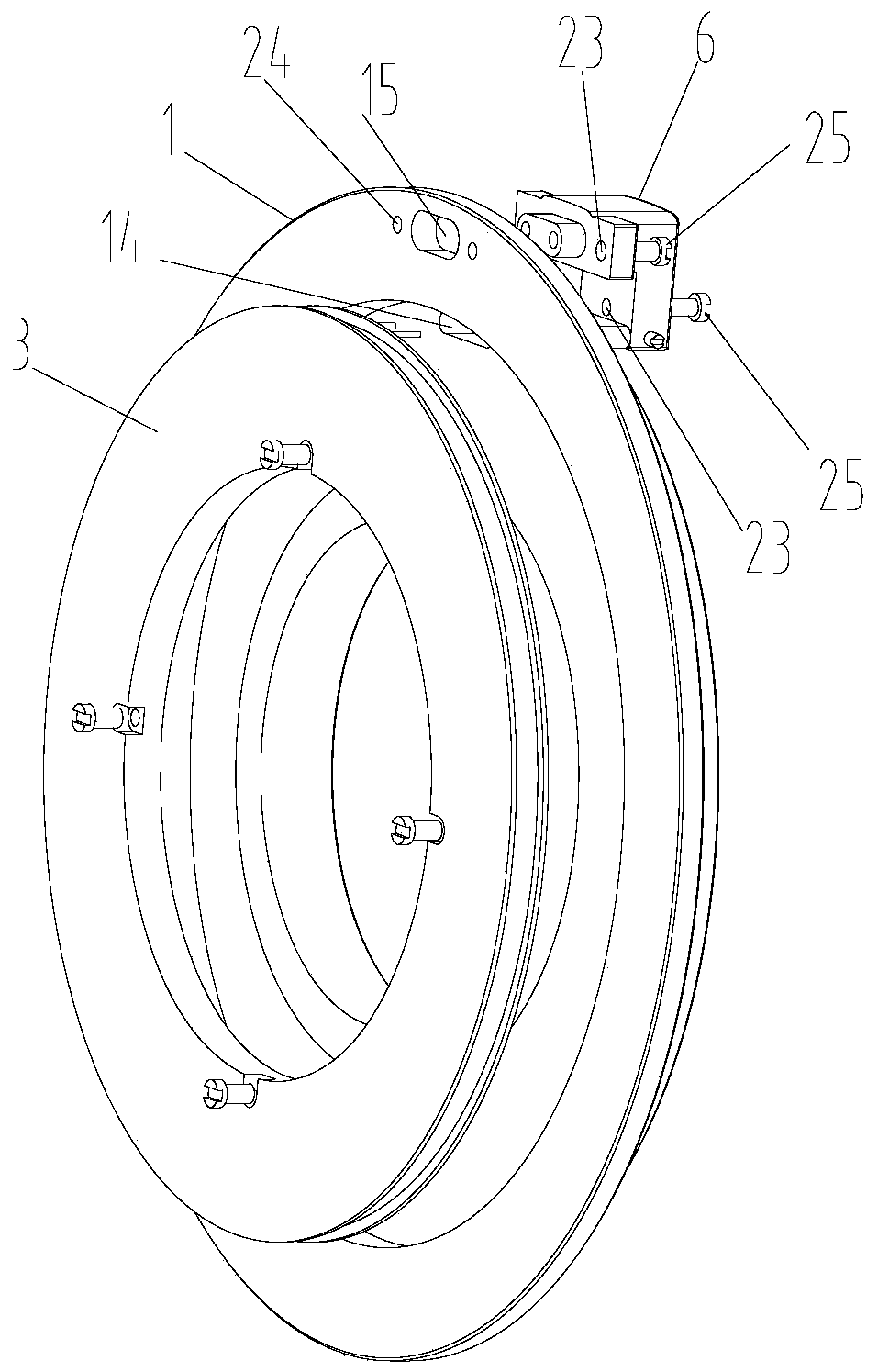

[0033] combined with Figure 1-9 As shown, this embodiment provides a wiring device for magnetic suspension bearings. In order to more clearly show the matching relationship between the wiring device and the magnetic suspension bearing, the attached figure 1 Also shows part of the magnetic suspension bearing, and by attaching figure 2 and 3 Further explain the relationship between the two.

[0034] combined with Figure 1-3 As shown, the magnetic suspension bearing of this embodiment includes an outer iron core 1, an inner iron core 2 and a control winding 3, the number of outer iron cores 1 is two, and the two outer iron cores 1 are symmetrically arranged on both sides of the inner iron core 2 , since the magnetic suspension bearing can be regarded as a symmetrical structure, so the figure 2 and image 3 Only one side of the outer core 1 is shown.

[0035] recombine figure 1 As shown, the control winding 3 of this embodiment is arranged between the two outer iron cor...

Embodiment 2

[0049] This embodiment provides a compressor, which has the wiring device and the magnetic suspension bearing as described in the first embodiment. Since the improvement of the compressor of this embodiment is only the wiring device and the magnetic suspension bearing, the rest of the structure of the compressor It is the same as the prior art, so this embodiment does not describe the compressor, nor describe other components of the compressor, but those skilled in the art can fully understand the above structure.

Embodiment 3

[0051] This embodiment provides a refrigeration device, which may be an air conditioner, which has the compressor described in Embodiment 2. Similarly, the improvement of the refrigeration device in this embodiment is only the wiring device of the compressor and magnetic suspension bearings, while the rest of the structure of the refrigeration equipment is the same as the prior art, so this embodiment does not illustrate the refrigeration equipment with drawings.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com