Multi-speed transmission and automobile

A transmission and clutch technology, which is applied to gear transmissions, elements with teeth, belts/chains/gears, etc., can solve the problems of poor fuel economy, poor riding comfort, and large shift impact of the whole vehicle, and achieve a compact structure. , The effect of improving fuel economy and fast skipping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

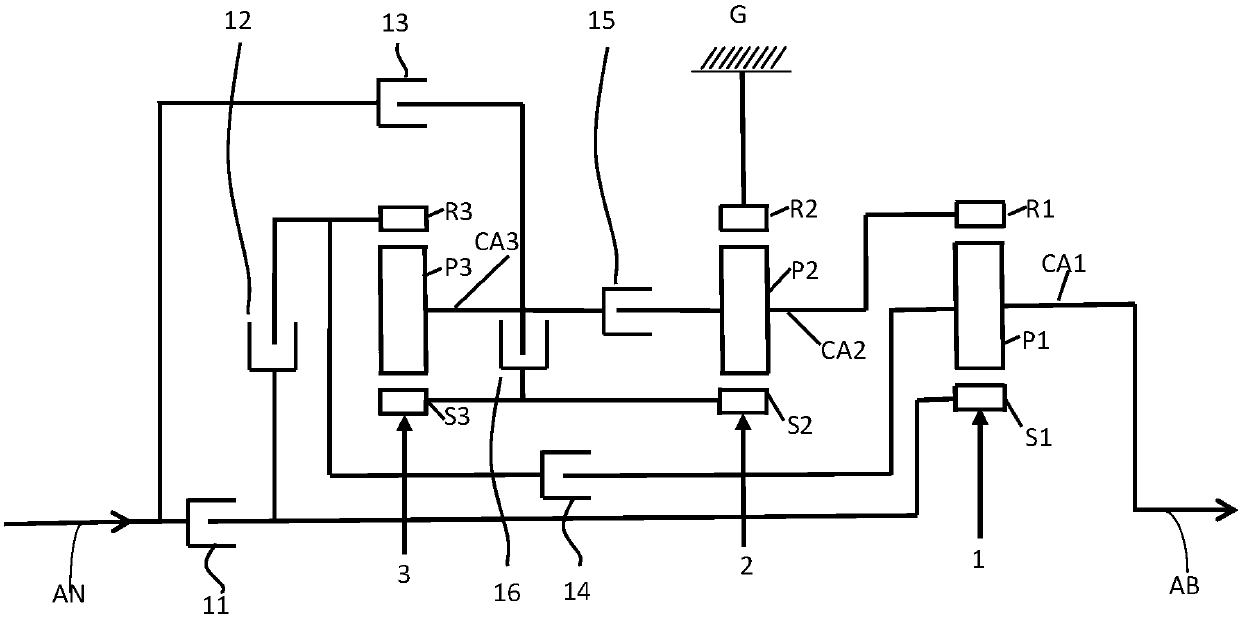

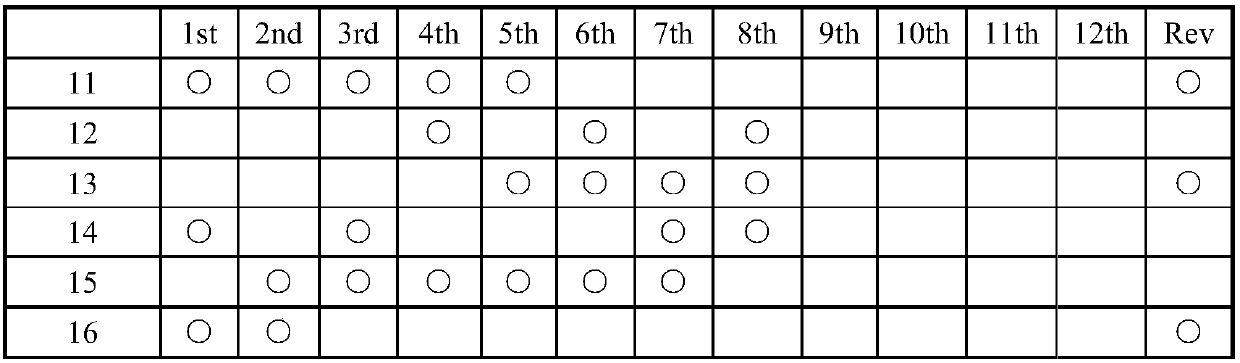

[0030] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0031] The present invention aims at the problems of the prior art multi-stage transmission, uses three planetary gear sets and five switching elements to realize six forward gears and one reverse gear, and realizes fewer gears, so that the engine cannot often work at its fuel economy Optimum area, resulting in poor fuel economy of the vehicle, large shifting impact, and poor ride comfort. Four planetary gear sets and six switching elements are used to realize nine forward gears and one reverse gear. The structure is relatively complicated and the volume is large. , more gear sets make the cost high; provide a multi-stage transmission, by using three planetary gear sets and six switching elements, at least eight forward gears and one reverse gear can be r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com