Embedded load sensor

A load sensor and embedded technology, applied in the direction of instruments, measuring devices, measuring force, etc., can solve the problems of poor applicability and achieve the effect of easy processing and manufacturing, small size and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to better explain the present invention and facilitate understanding, the present invention will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

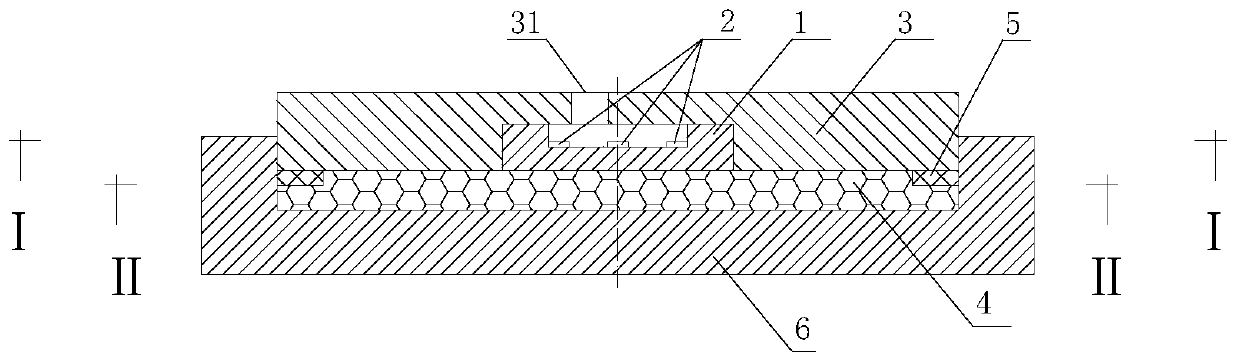

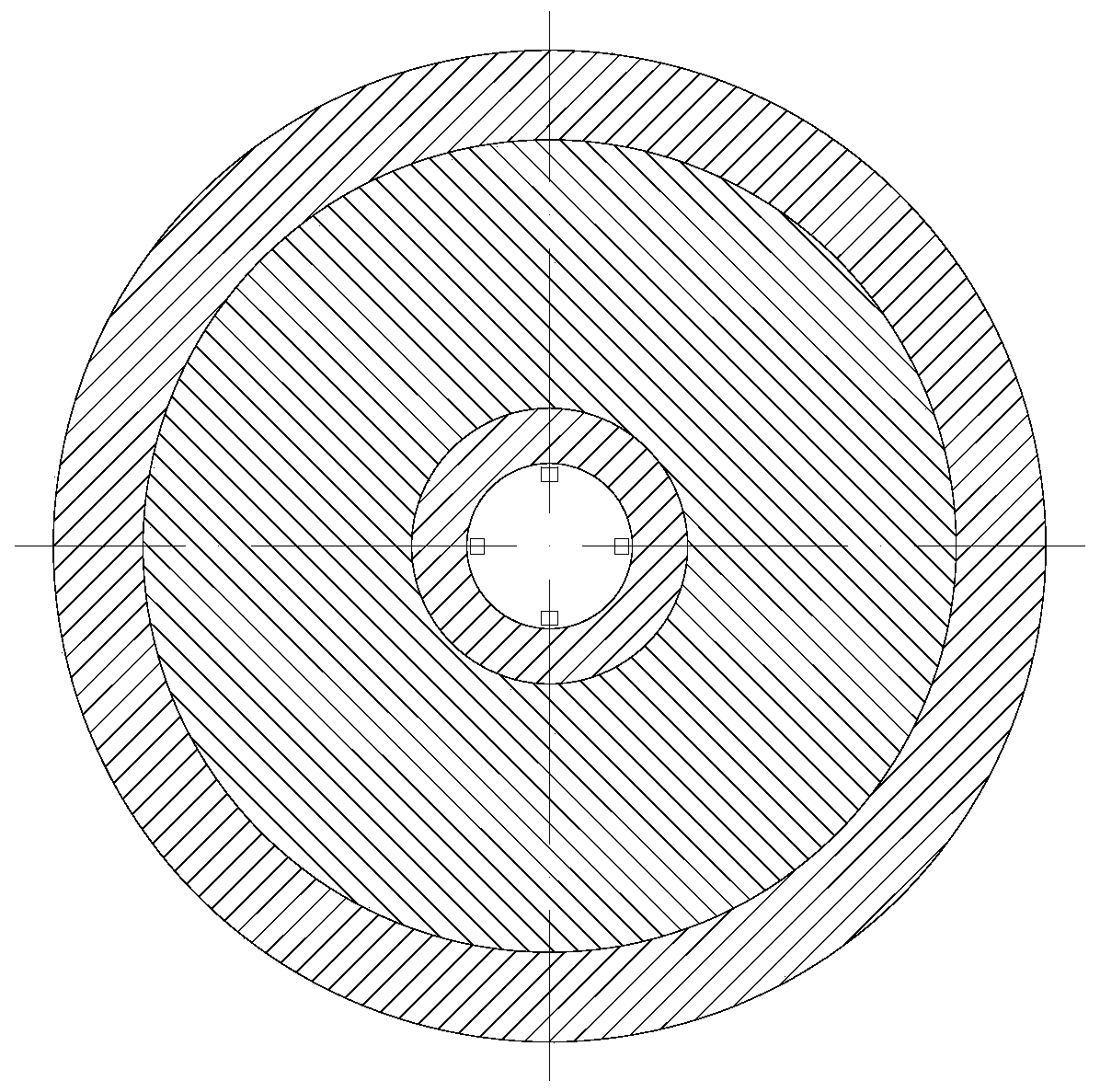

[0038] like Figure 1 to Figure 3 As shown, the present invention discloses an embedded load sensor, which includes a metal elastic body 1 , a strain gauge 2 , a substrate 3 , a solid rheological body 4 and a base 6 .

[0039] The substrate 3 is provided with a groove, and the metal elastic body 1 is embedded in the groove, and the lower surface of the metal elastic body 1 and the lower surface of the substrate 3 are in the same plane.

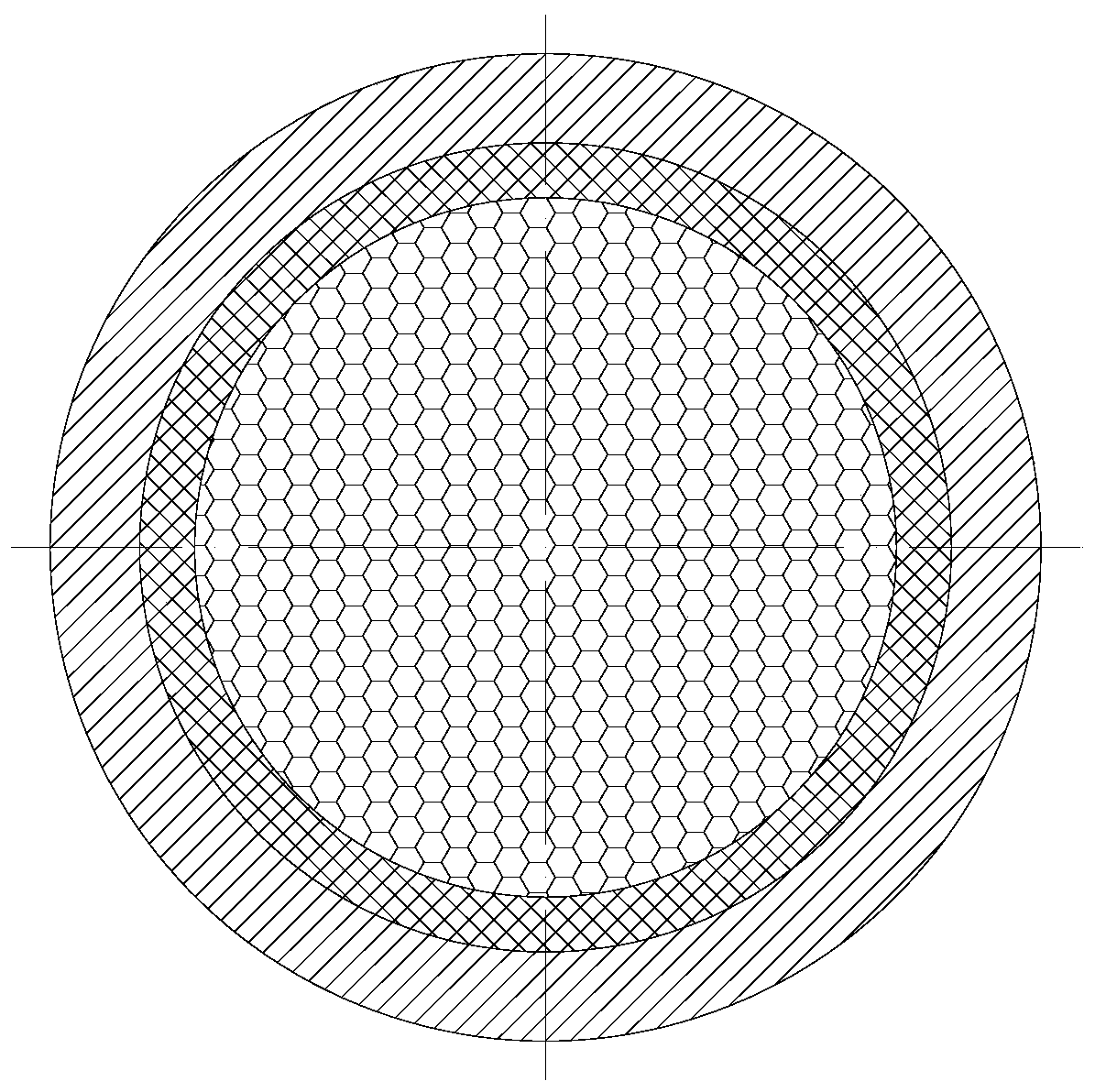

[0040] A closed space is formed between the substrate 3 and the base 6, and the solid rheological body 4 is arranged in the closed space.

[0041] A first groove is provided on the surface of the metal elastic body 1 away from the base 6 , and a plurality of strain gauges 2 are arranged at the bottom of the first groove.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com